Broken stream type aerating apparatus of laying air in two layers

A technology of aeration device and air distribution, which is applied in aeration device, double-layer air-distributing diffuse-flow aeration device, and sewage biochemical treatment engineering field, can solve the problem of insufficient uniform aeration, aeration dead zone, and poor dissolved oxygen performance. It can improve the dissolved oxygen performance, avoid dead zone, uniform gas change and scouring effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

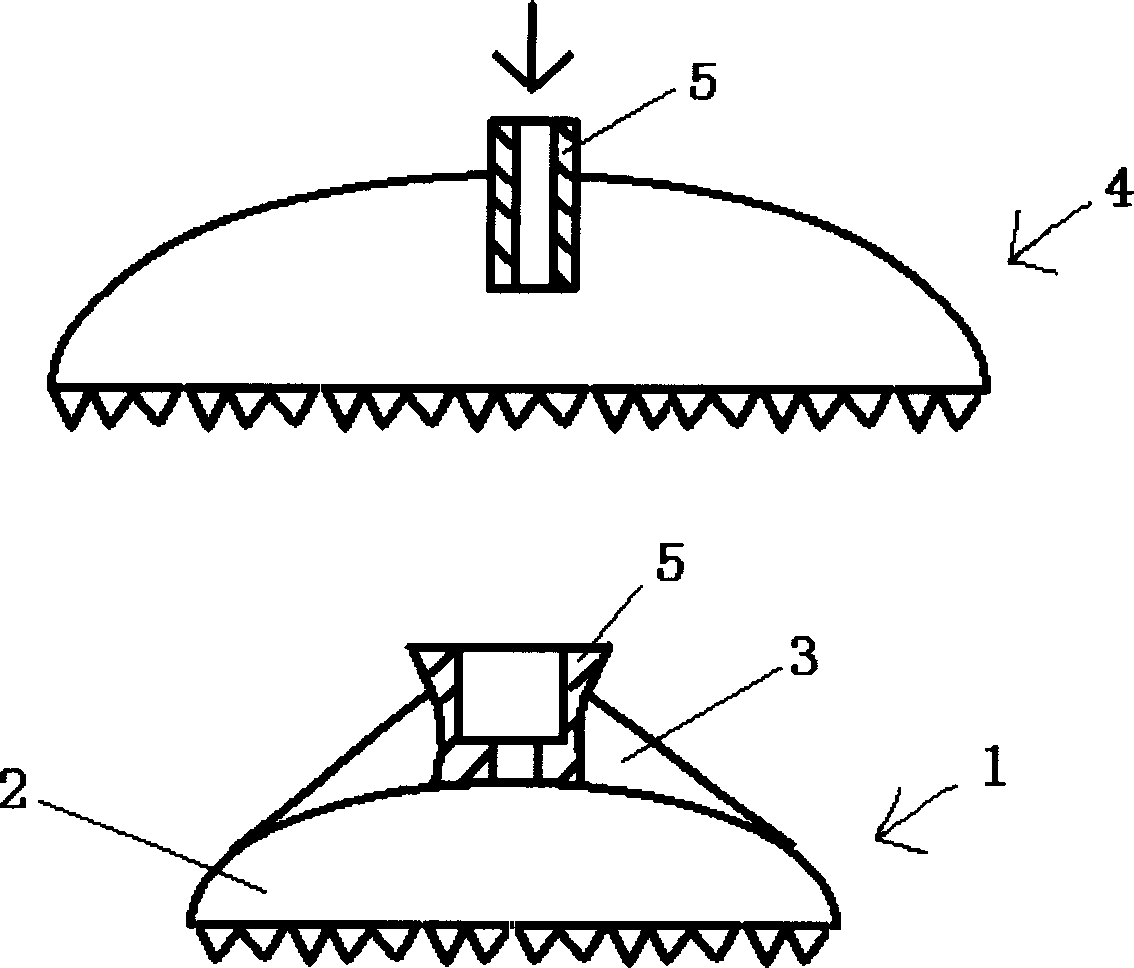

[0013] Such as figure 1 , figure 2 and image 3 As shown, a double-layer air distribution and diffuse flow aeration device of the present invention includes a zigzag air distribution head 1, and the zigzag air distribution head 1 is provided with a sawtooth air distribution plate 2 and an air distribution plate 2 on the periphery. The upper end surface of the board is vertically connected with a flow guide partition 3, wherein a zigzag diffuser 4 is covered on the zigzag air distribution head 1, and the zigzag diffuser 4 is concave Disc shape, and is provided with a plurality of sawtooth around it, and said sawtooth diffuser cover 4 is connected with the sawtooth air distribution head 1 through the center pipe 5 at its center.

[0014] Further, a plurality of small aeration holes 6 are provided in the middle of the zigzag diffuser 4 .

[0015] Further, 60 sawtooths are arranged around the sawtooth diffuser 4 .

[0016] Furthermore, 12 small aeration holes 6 are provided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com