Plant for the preparation of materials

A material processing and equipment technology, applied in the field of material processing equipment, can solve problems such as difficulty in combining additional processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

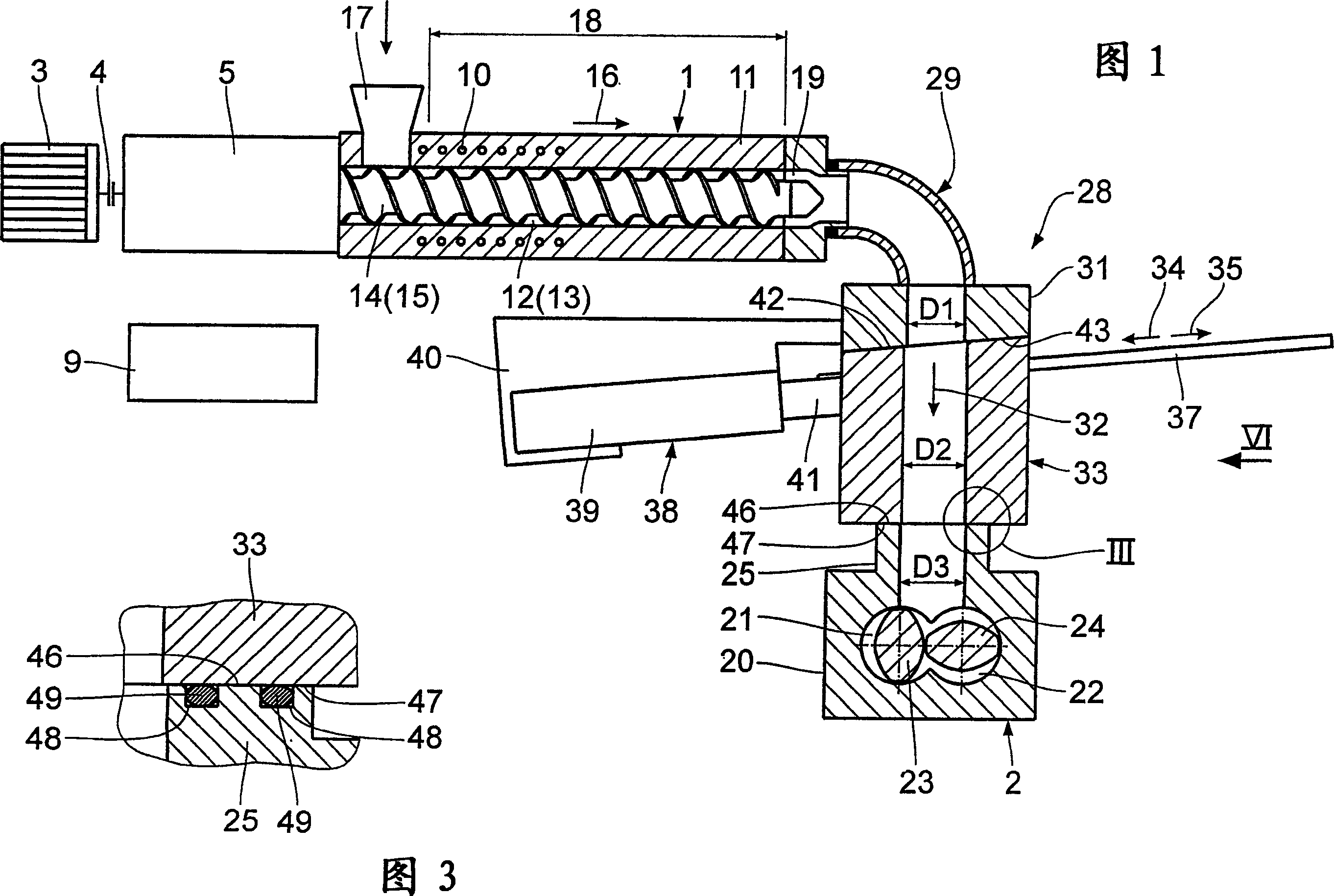

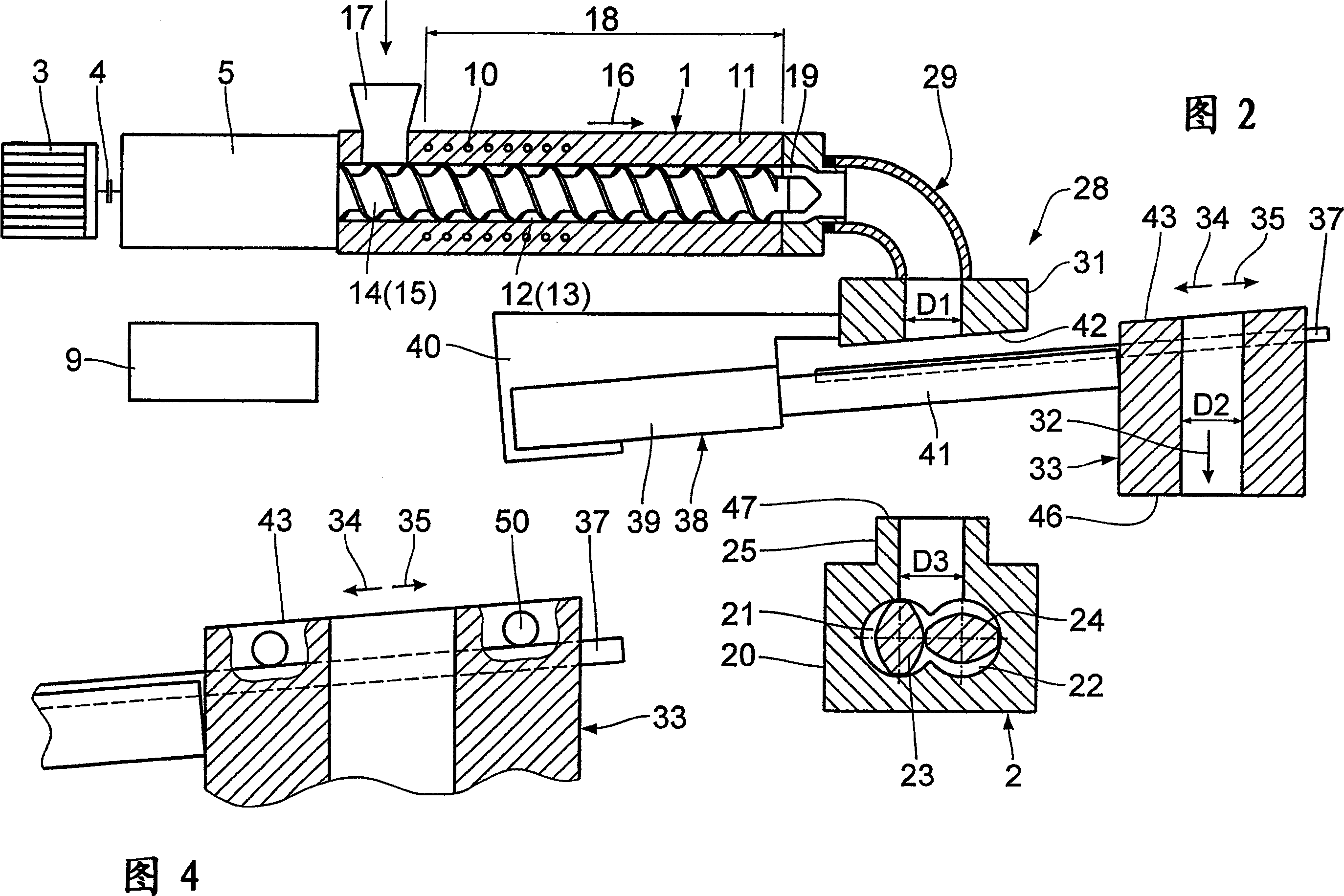

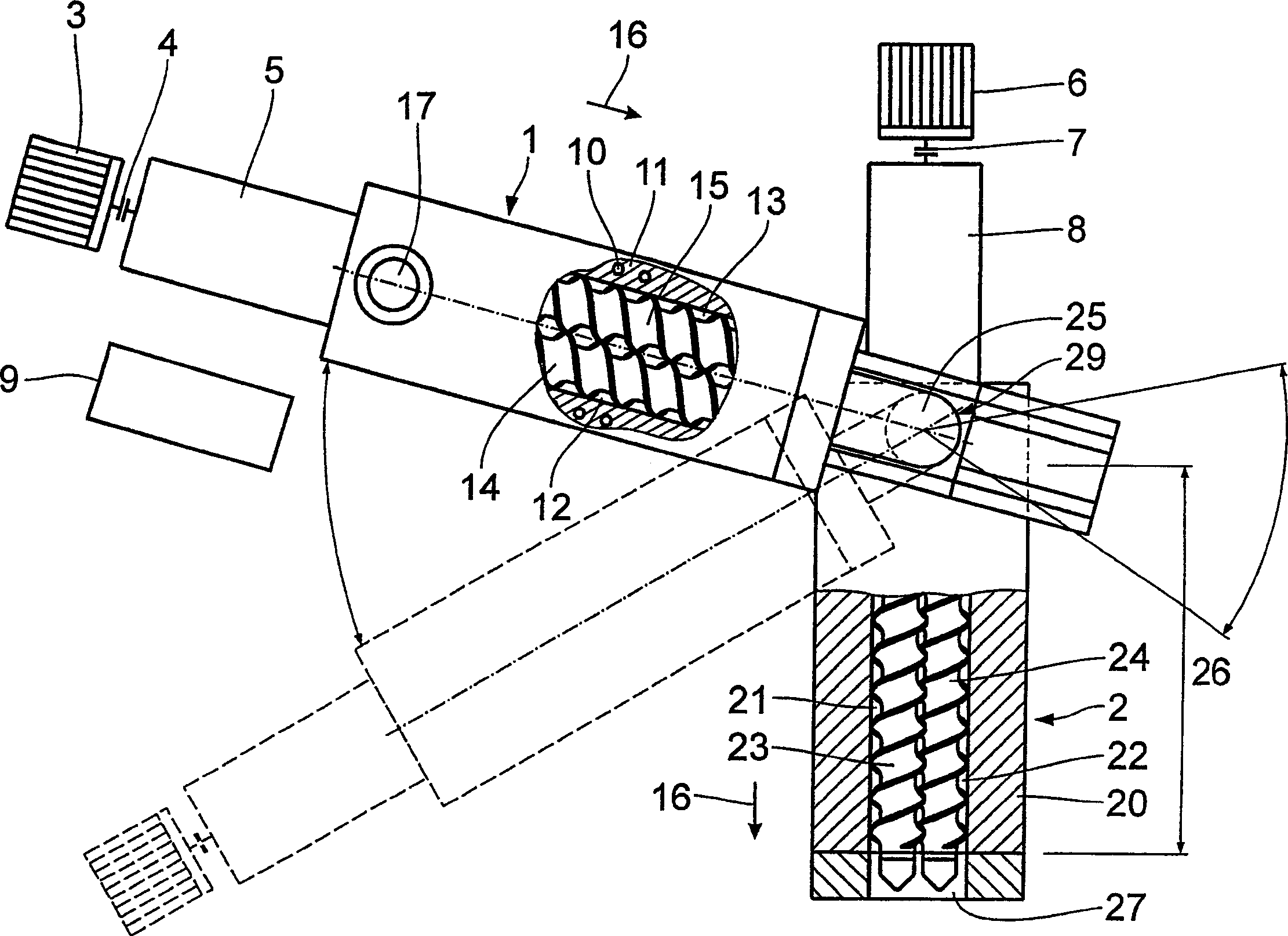

[0025] The first exemplary embodiment shown in FIGS. 1 to 5 includes a first extruder 1 and a second extruder 2 . The first extruder 1 is arranged above the second extruder 2 . The first extruder 1 is driven by a first electric motor 3 via a first coupling 4 and a first transmission 5 . The second extruder 2 is driven by a second electric motor 6 via a second coupling 7 and a second transmission 8 . The electric motors 3 and 6 are controlled by a control device 9 .

[0026] The first extruder 1 comprises a housing 11 provided with a heating system 10, in which are formed two first housing holes 12, 13 extending parallel to each other and joining each other in an approximately "8" shape. The two first screw shafts 14 , 15 , which are coupled to the first transmission 5 , are arranged in the two housing bores 12 , 13 . The screw shafts 14, 15 are driven in the same or opposite directions. The first extruder 1 comprises a downstream feed hopper 17 arranged in the conveying di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com