Full automatically punching binding equipment and method thereof

A binding equipment, fully automatic technology, applied in binding and other directions, can solve the problems of low life, various faults, and the inability to realize automatic punching and binding, etc., and achieve the effect of high thickness, simple and reasonable structure, which is beneficial to environmental protection and human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

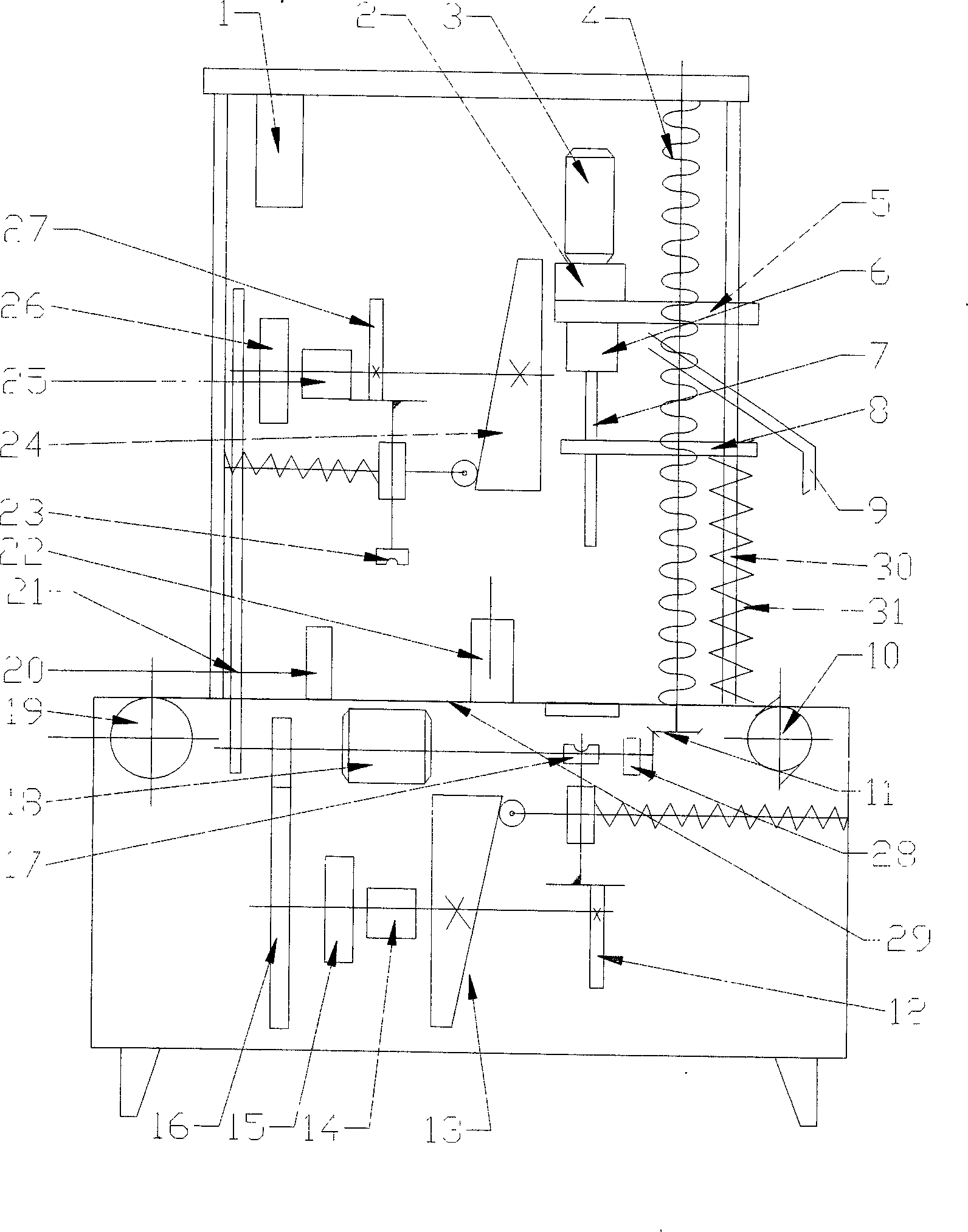

[0048] Below in conjunction with accompanying drawing, the utility model is described in further detail.

[0049] Such as figure 1 , Figure 3-1 and Figure 3-2 As shown, the punching and binding machines in the prior art generally use a gear-rack transmission system in the punching process, and the main problem of its existence is that under the rated punching depth (ie, binding thickness) The failure rate of transmission parts of the system is high. The performance is: the meshing gap of the open rack and pinion transmission is unstable, and the teeth on the gear or rack are deformed or broken. Its reason is: when the binding paper intensity is higher, along with hollow drill bit 7 drills deeply, the resistance of paper to drill bit becomes larger, when shredded paper scraps are discharged from hollow drill bit 7, also further increased the drill bit. Resistance, therefore, makes the above-mentioned problems occur in the pinion-rack feeding system that requires high inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com