Chassis base assembly, method of manufacturing the chassis base assembly and plasma display panel (PDP) assembly using the chassis base assembly

A technology of plasma and plate assembly, which is applied in the manufacture of ships or lead-in wires, pipe structure parts, solid cathode parts, etc., and can solve problems such as the inability to maintain consistent rib heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

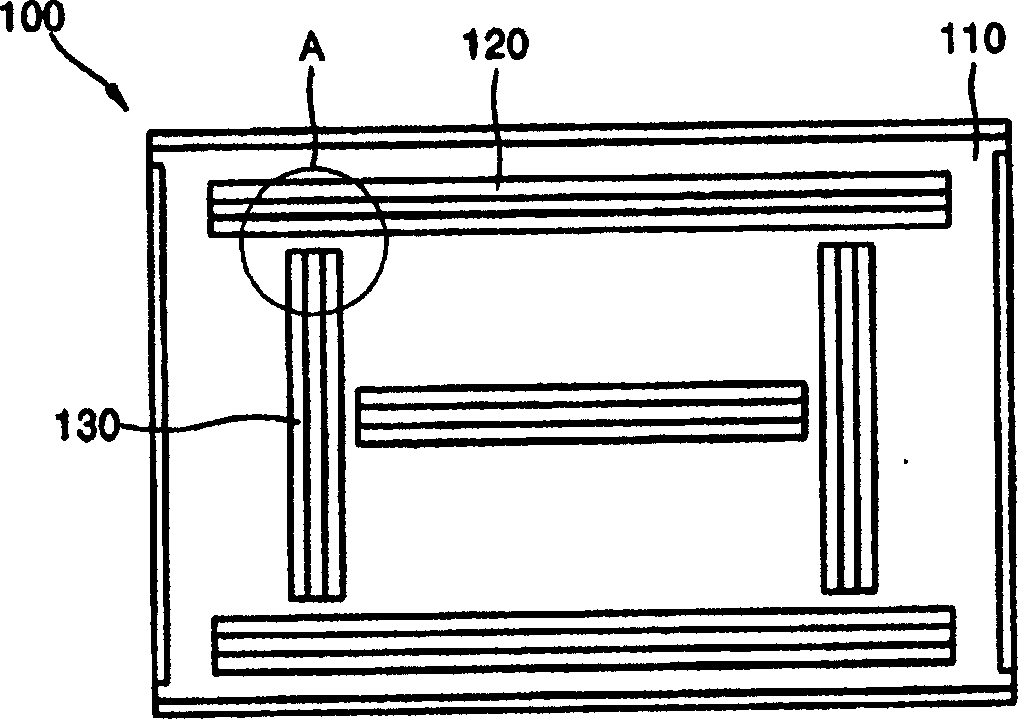

[0028] refer to figure 1 , the floor assembly 100 includes a floor 110 and first and second floor reinforcing members 120 and 130 attached to a rear surface of the floor 110 .

[0029] First and second floor reinforcing members 120 and 130 are attached to the floor 110 to reinforce the strength of the floor 110 . The first floor reinforcement members 120 are horizontally attached to upper and lower ends of the rear surface of the floor panel 110 , and the second floor reinforcement members 130 are vertically attached to left and right ends of the rear surface of the floor panel 110 . Each of the first and second floor reinforcement members 120 and 130 is respectively formed in a bar shape and independently attached to the floor 110 .

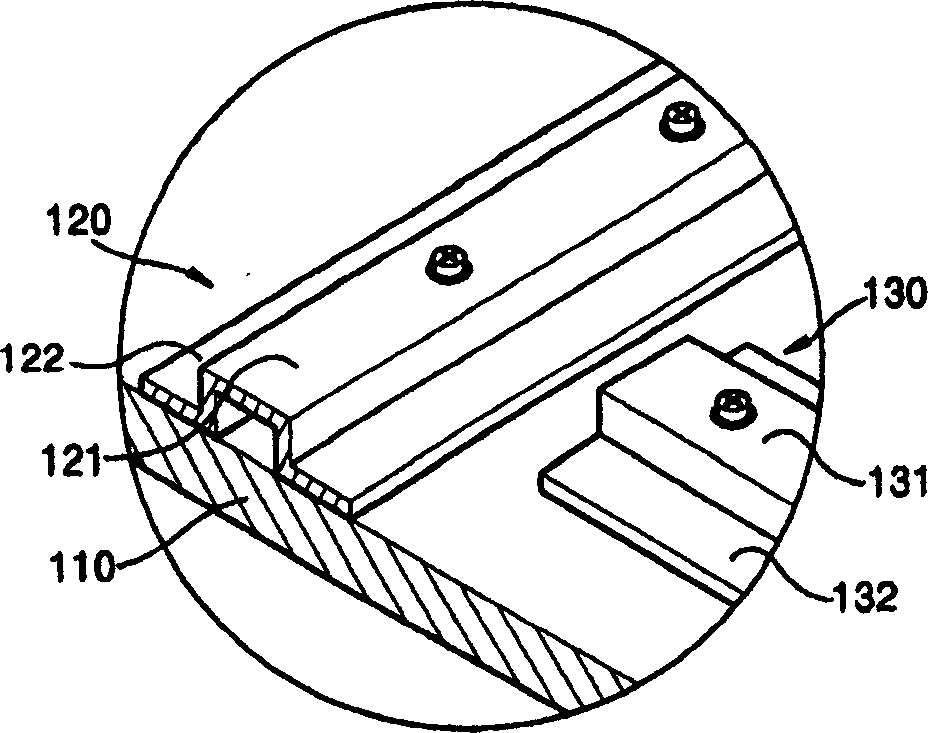

[0030] refer to figure 2 , each first floor reinforcing member 120 includes a first rib 121 having a bar shape and first flanges 122 bent from both ends of the first rib 121, and each second floor reinforcing member 130 includes a bar-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com