LED structure

A light-emitting diode, N-type technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of maintaining light-emitting/illumination performance, insufficient light-emitting diode structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention will now be described with reference to the drawings. Among them, different parts of some components are not drawn according to actual size. Certain dimensions are shown exaggerated in relation to other parts to provide a clearer description and to assist those skilled in the art in understanding the present invention.

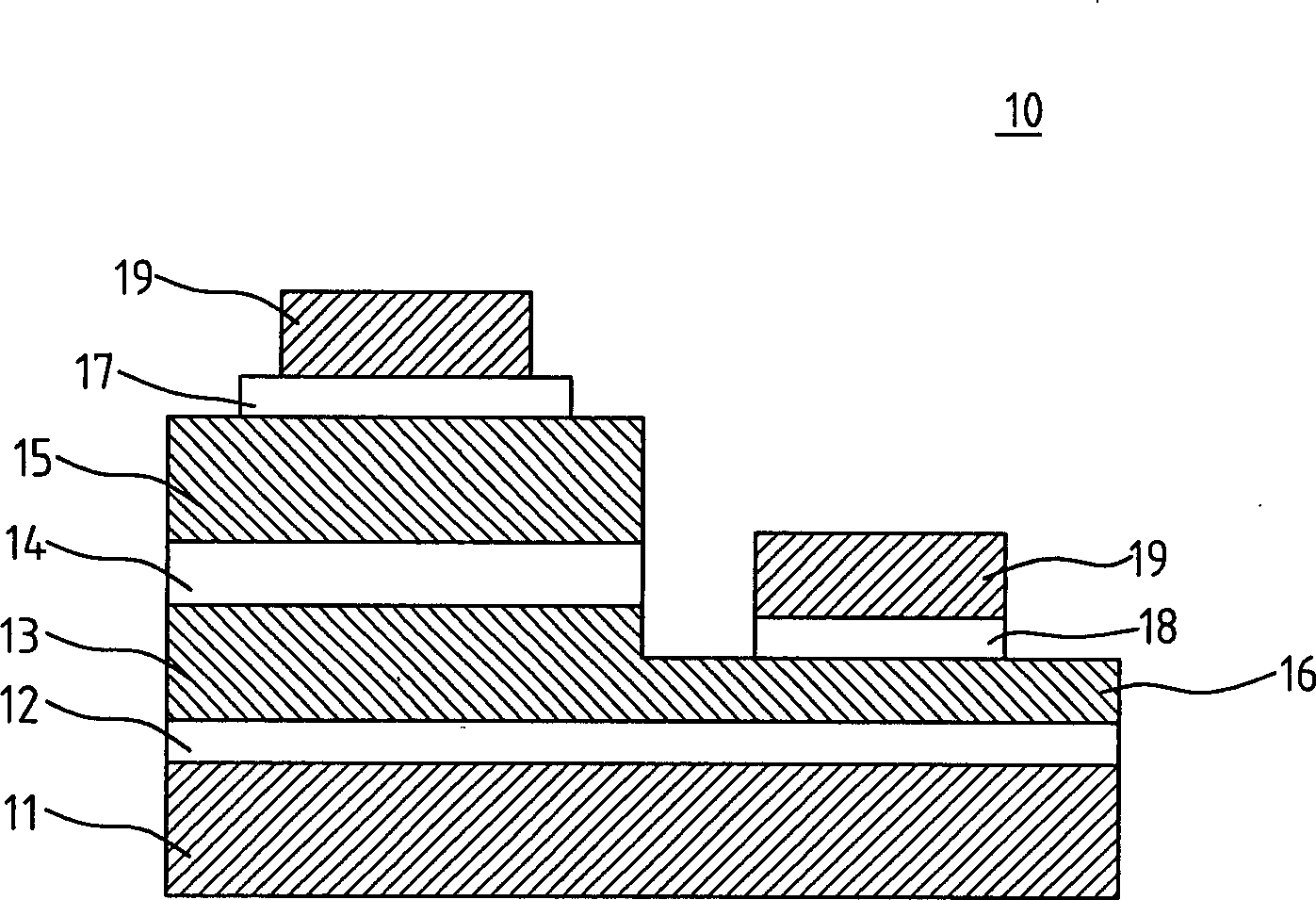

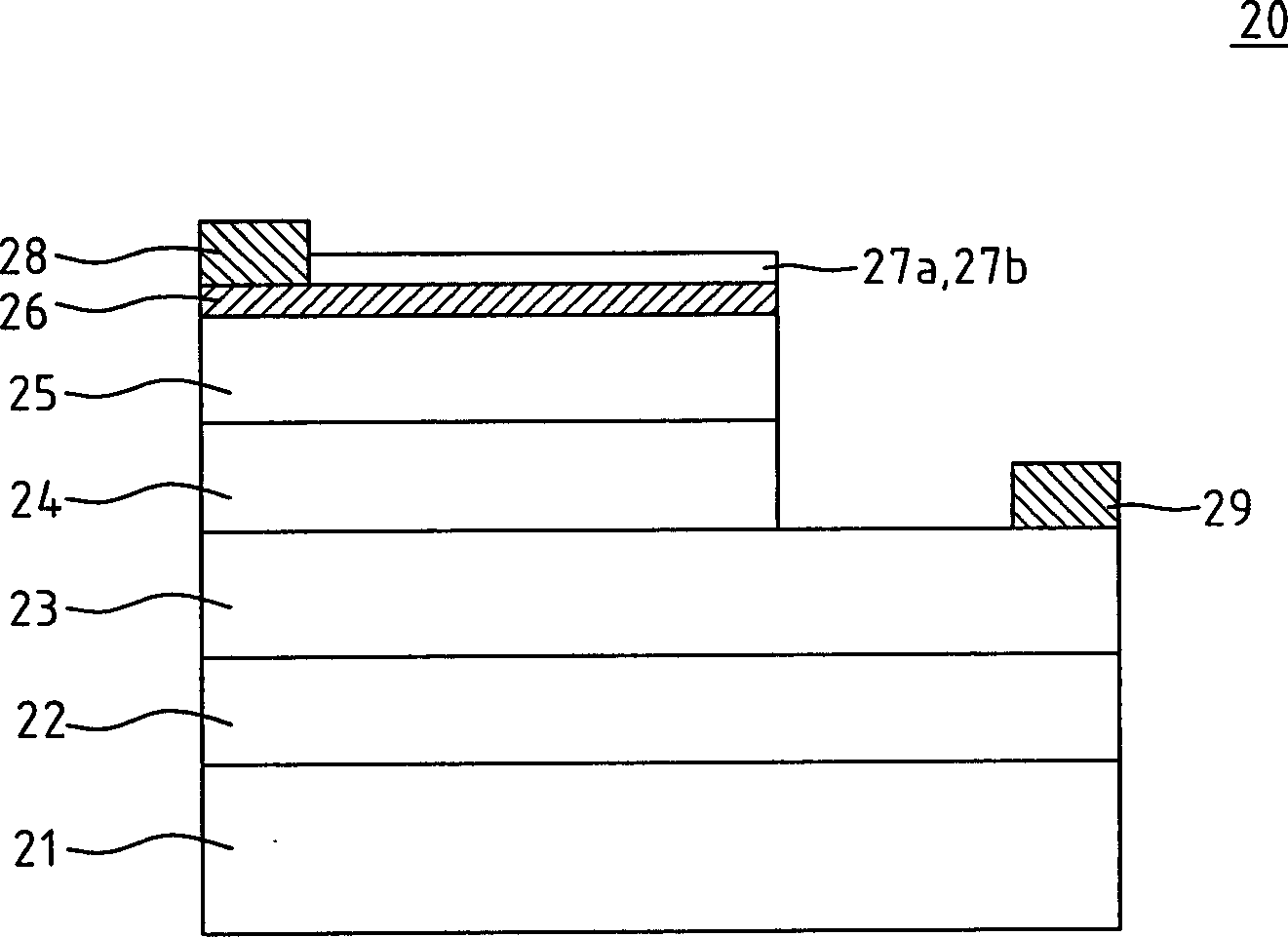

[0055] First, please refer to figure 2 . figure 2 shows a gallium nitride-based light-emitting diode structure 20 according to an embodiment of the present invention with improved reverse voltage and antistatic functions, which includes: a substrate 21, a buffer layer 22, an N-type gallium nitride-based (GaN) layer 23, a light-emitting Stack layer 24 , P-type gallium nitride (GaN) layer 25 , digital pass-through layer 26 , transparent conductive layer 27 a or transparent conductive oxide layer 27 b , first ohmic electrode 28 , and second ohmic electrode 29 .

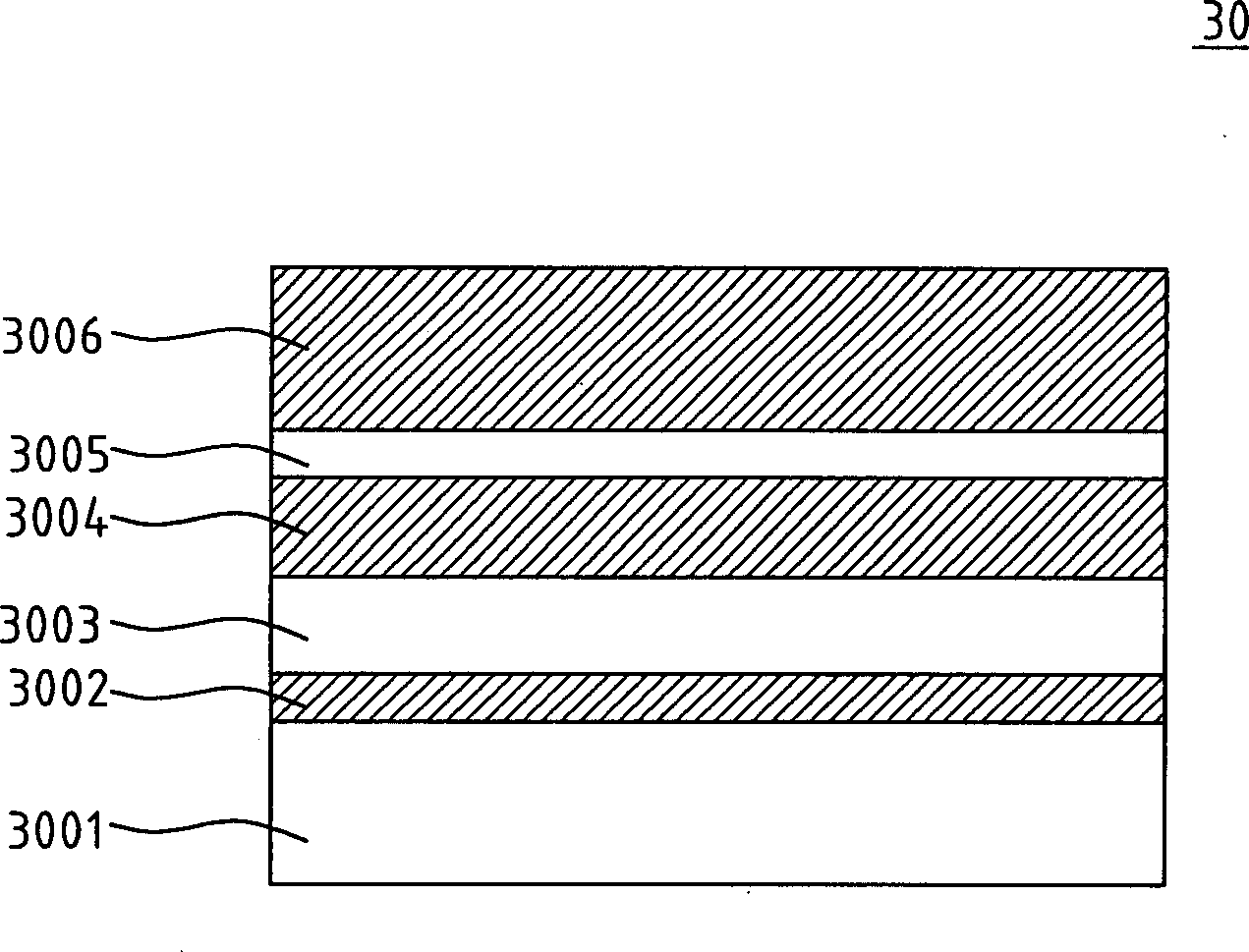

[0056]In the above structure, the bottom layer of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com