Surface roughness measuring method and apparatus and turbine deterioration diagnostic method

A technology of surface roughness and measurement method, applied in measurement devices, mechanical equipment, engine components, etc., can solve problems such as expensive, large lens parts, and optical devices susceptible to vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

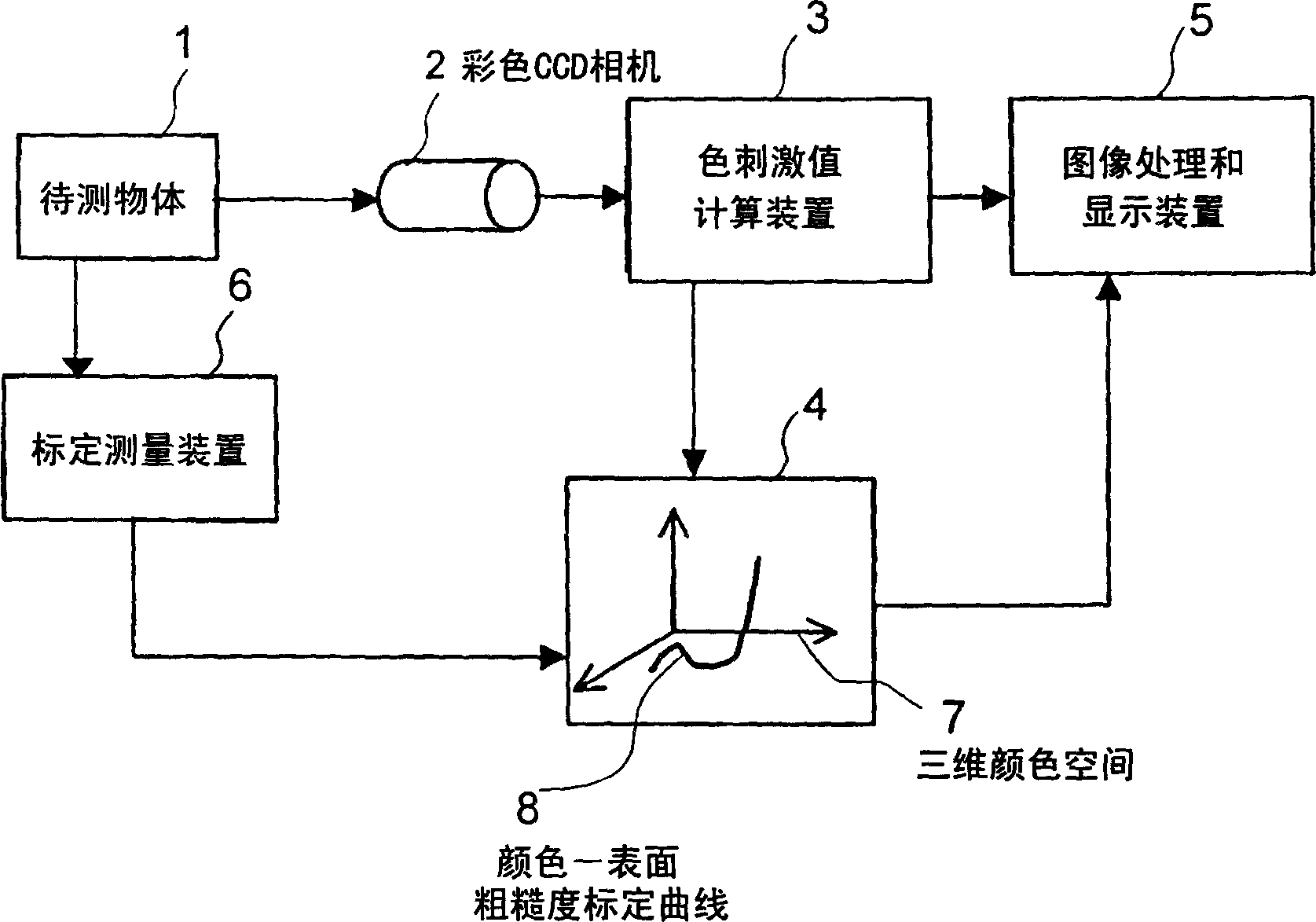

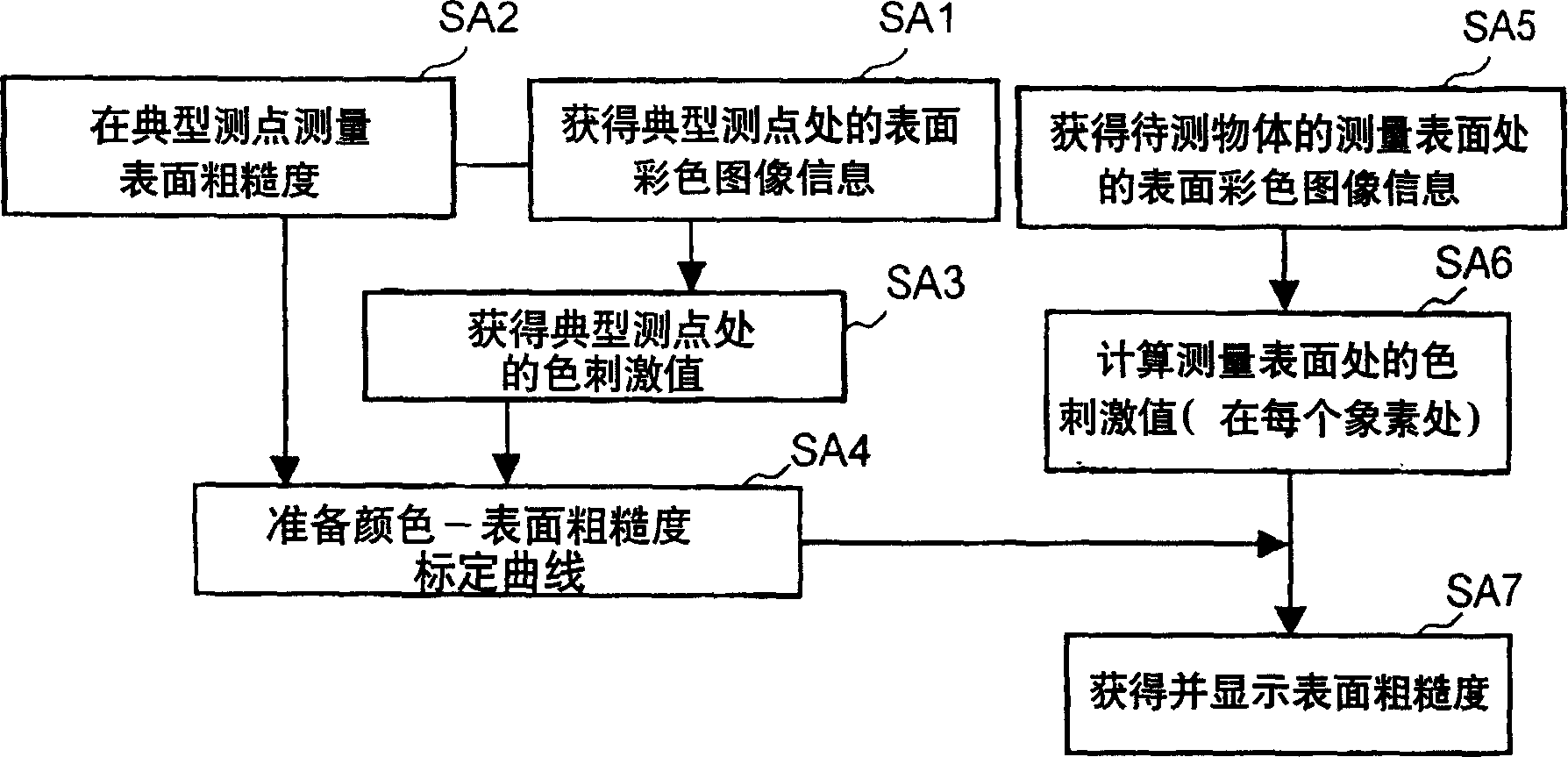

[0035] figure 2 is a block diagram showing a surface roughness measuring device according to a first embodiment of the present invention. This embodiment comprises color CCD (charge-coupled device) camera 2, color stimulus value calculation device 3, database 4, graphics processing and display unit 5 and calibration measurement device 6, wherein color CCD camera 2 is a color imaging device, and it is installed on the The opposite side of the measuring object 1 such as a turbine blade.

[0036] As the color CCD camera 2, a digital still camera or a digital television camera for easy data transfer with an image processing and display device 5 such as a personal computer is used. The color CCD camera 2 includes many pixels, and acquires color image information of the surface of the object 1 to be measured, such as a turbine blade. The color stimulus value calculation section 3 performs various image processing such as noise processing and averaging processing for color image i...

no. 2 example

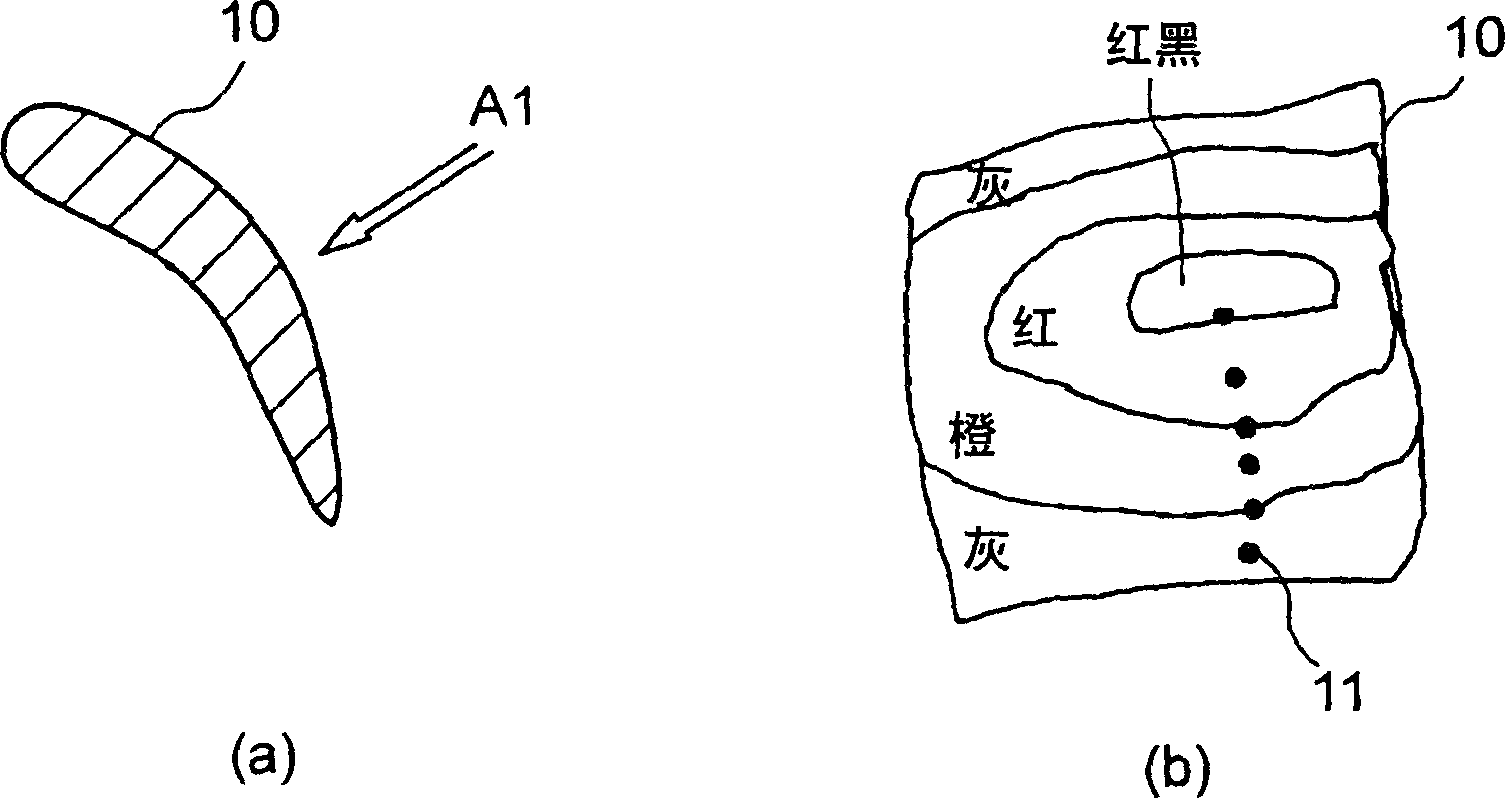

[0043] Figure 4 is schematically shown when passing through the color CCD camera 2 pairs of figure 1 The correspondence of pixels 12 to typical measuring points 11 is shown for measurements taken on the backside of a turbine blade 10 . exist Figure 4 Among them, (a) is a graph showing a state where the axis of the coordinate system is set on the surface of the turbine blade 10, and (b) is a graph showing a state where pixels are set in (a). Suppose the backside of the turbine blade 10 is measured at pixel 100(X)×100(Y), and as a typical measuring point 11 on the backside of the blade, for example, the gray part 11-1 corresponds to the pixel position (X, Y ) = the area at (80, 10). The color information (for example, red, green and blue values) of the pixel area is acquired and recorded by the color CCD camera 2 and the color stimulus value calculation device 3 . When the region extends across multiple pixels, red, green and blue values corresponding to each pixel are ...

no. 3 example

[0047] Figure 6 The database shown in uses the red, green and blue values as the tristimulus values, and forms the RGB space as the three-dimensional space 7 constituted by the axes of the coordinate system of the red, green and blue color stimulus values, and relies on The red, green and blue values of the surface color that vary depending on the surface roughness of the object 1 to be measured are plotted in the space. Here, mark O denotes data obtained by interpolation with a predetermined roughness interval. In the second embodiment shown above Figure 5 In , the relationship between red, green, blue values and surface roughness is reasonably arranged in two-dimensional space, however in Figure 6 In , the exact same data is rationally rearranged in three-dimensional space. exist Figure 6 In , point A represents the position where the surface roughness is the smallest, and point D represents the position where the surface roughness is the largest. here, Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com