Cold xtrusion manufacturing method of cylindrical commutator

A manufacturing method, a cylindrical technology, applied in the manufacturing field of cylindrical commutators, which can solve problems affecting the performance of motors, poor outer roundness of commutators, complex sheet arrangement procedures, etc., to improve material utilization and production efficiency , Small radial runout, uniform arrangement of sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

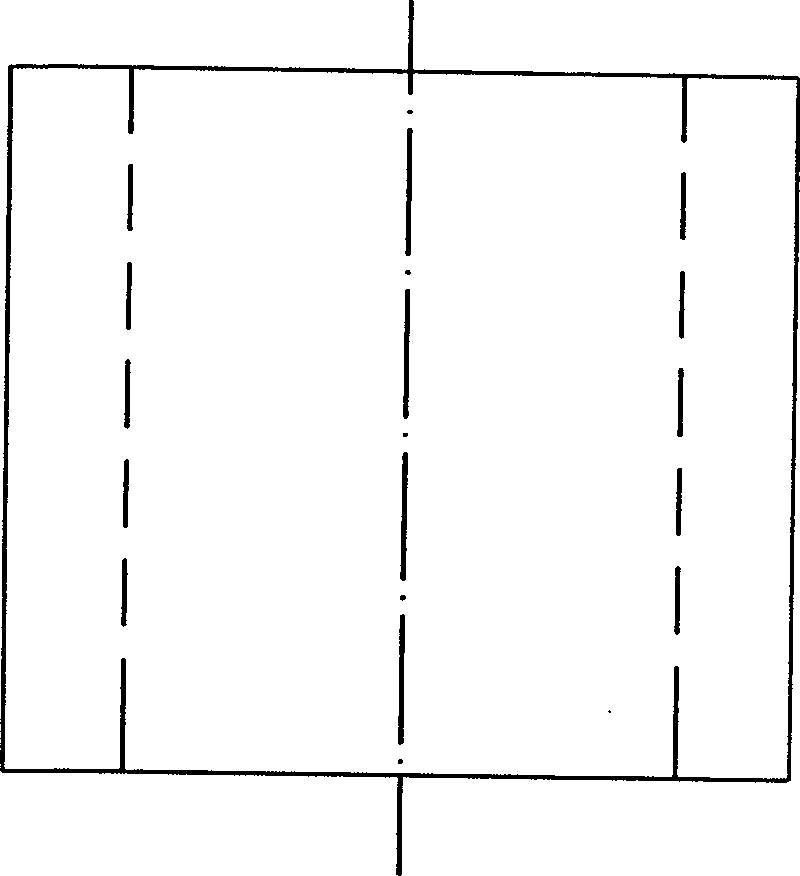

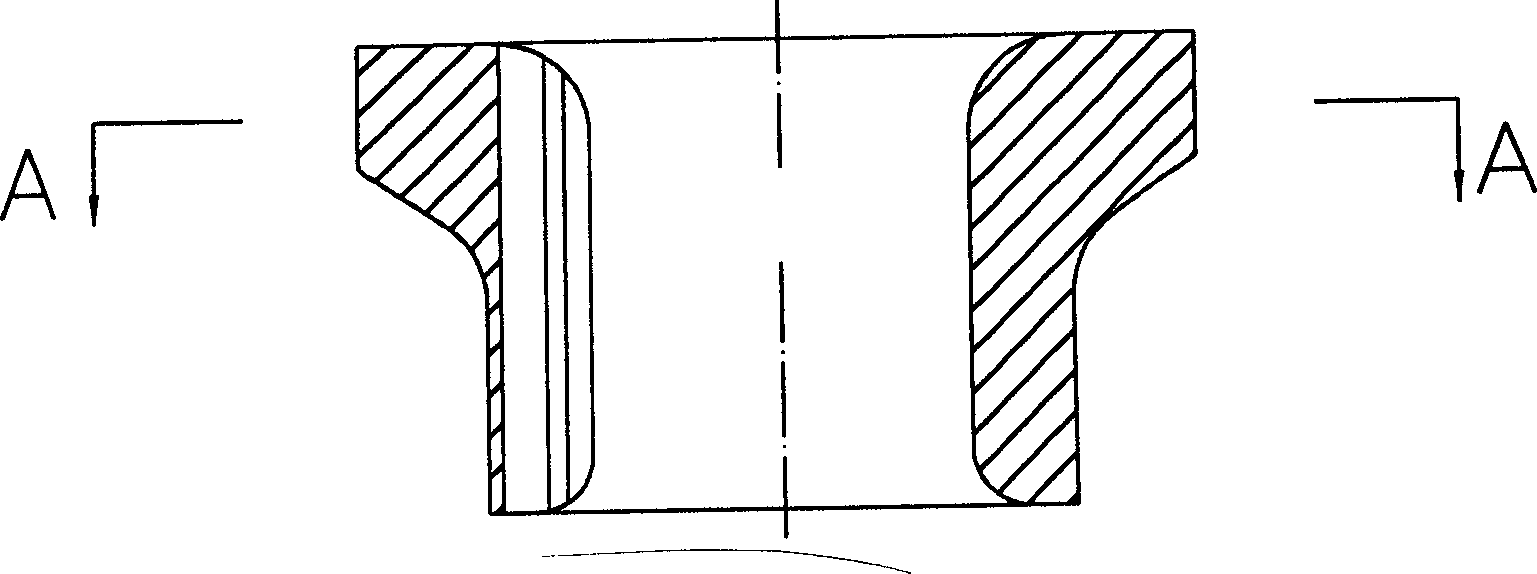

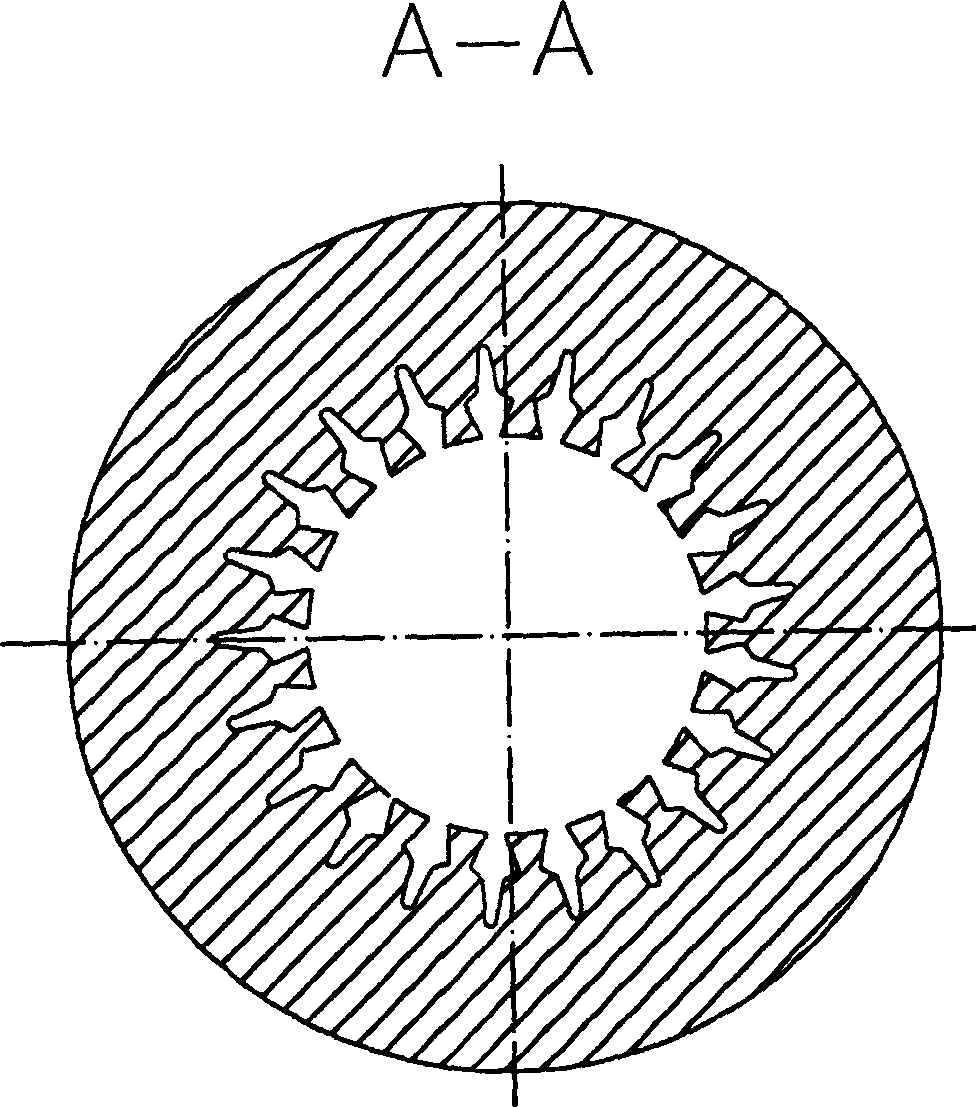

[0013] The cold extrusion manufacturing method of the cylindrical commutator of the present invention is as follows: firstly, the copper pipe (using a cutting machine) that is not much different from the outer diameter of the required commutator is cut into a length that is not much different from the length of the commutator segment of the product. Cylindrical tubing (such as figure 1 shown), after annealing, the cylindrical pipe (using a 100T hydraulic press and a special die for cold extrusion) is cold-extruded to form a double "7" cross-section (one positive and one reverse "7" ) Integral commutator segment body (such as figure 2 shown), its inner wall has the same number of internal teeth with a cup-shaped cross-section as the commutator segment (such as image 3 shown), to increase the contact area between the commutator piece and the molding compound, so that the mechanical strength of the commutator is improved; then it is made into a cylinder through pressing, curin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com