Recombinative production line scheduling method based on genetic algorithm

A production line scheduling and genetic algorithm technology, applied in the field of automatic control and information, can solve problems such as inability to adapt to reconfigurable production line production scheduling, scheduling algorithm structure separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples are provided in conjunction with the content of the present invention.

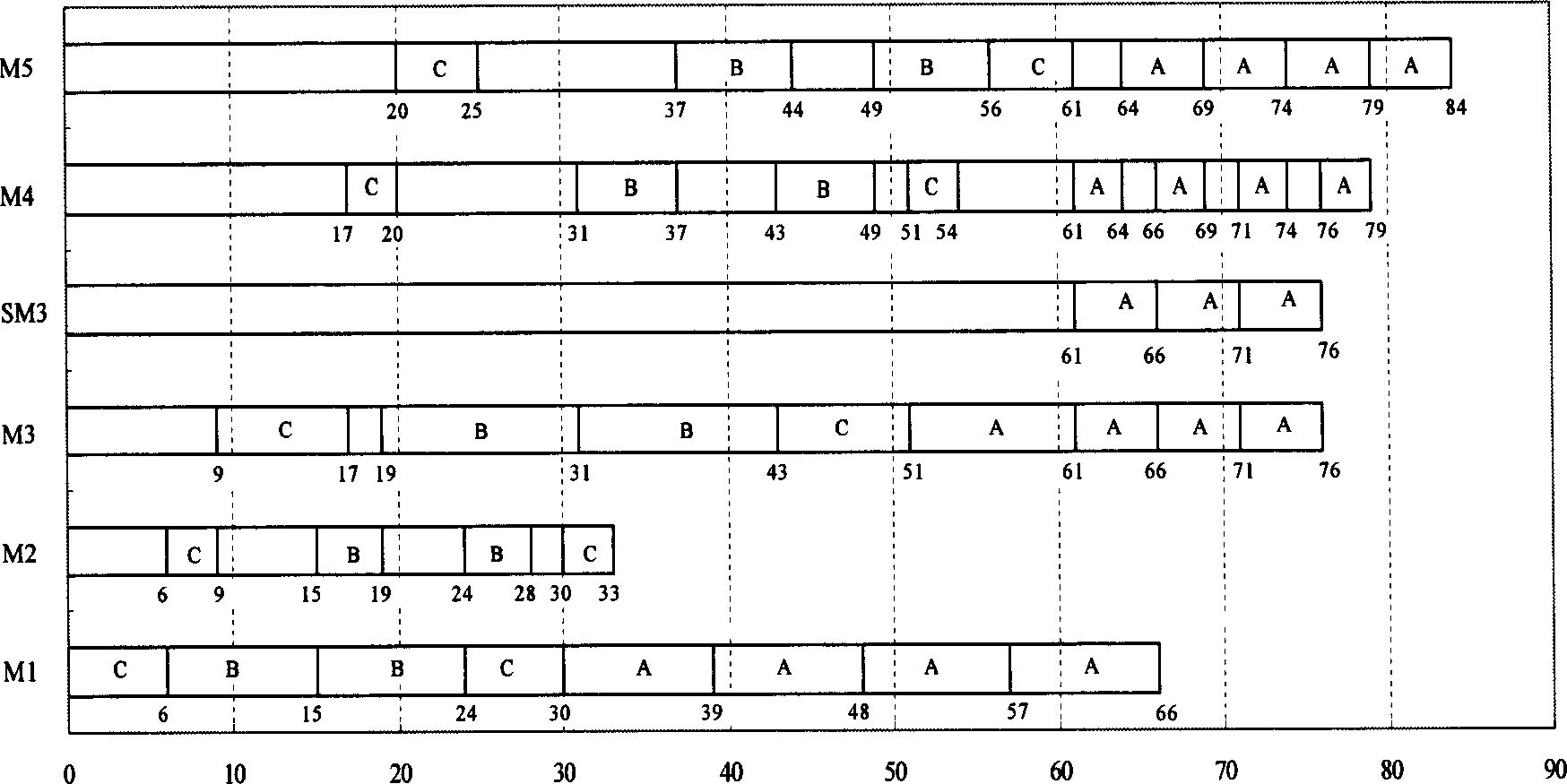

[0032] The reconfigurable motor production workshop includes five processes of processing equipment, including one process with reconfigurable processing equipment and one process with variable structure machine tools. The number of workpieces are 4, 4, 2 respectively. Also includes the master computer. The data stored in the memory of the computer includes the processing time, the number of processing and the delivery date of each process, and the calculation results can be sent to each processing equipment. By using such as liquid crystal display equipment, the processing order can be transmitted to the production line operator. Once the processing order displayed on the video display device is received, the operator puts the sorted product processing order into each processing equipment for processing. If the processing equipment is fully automatic, the main control comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com