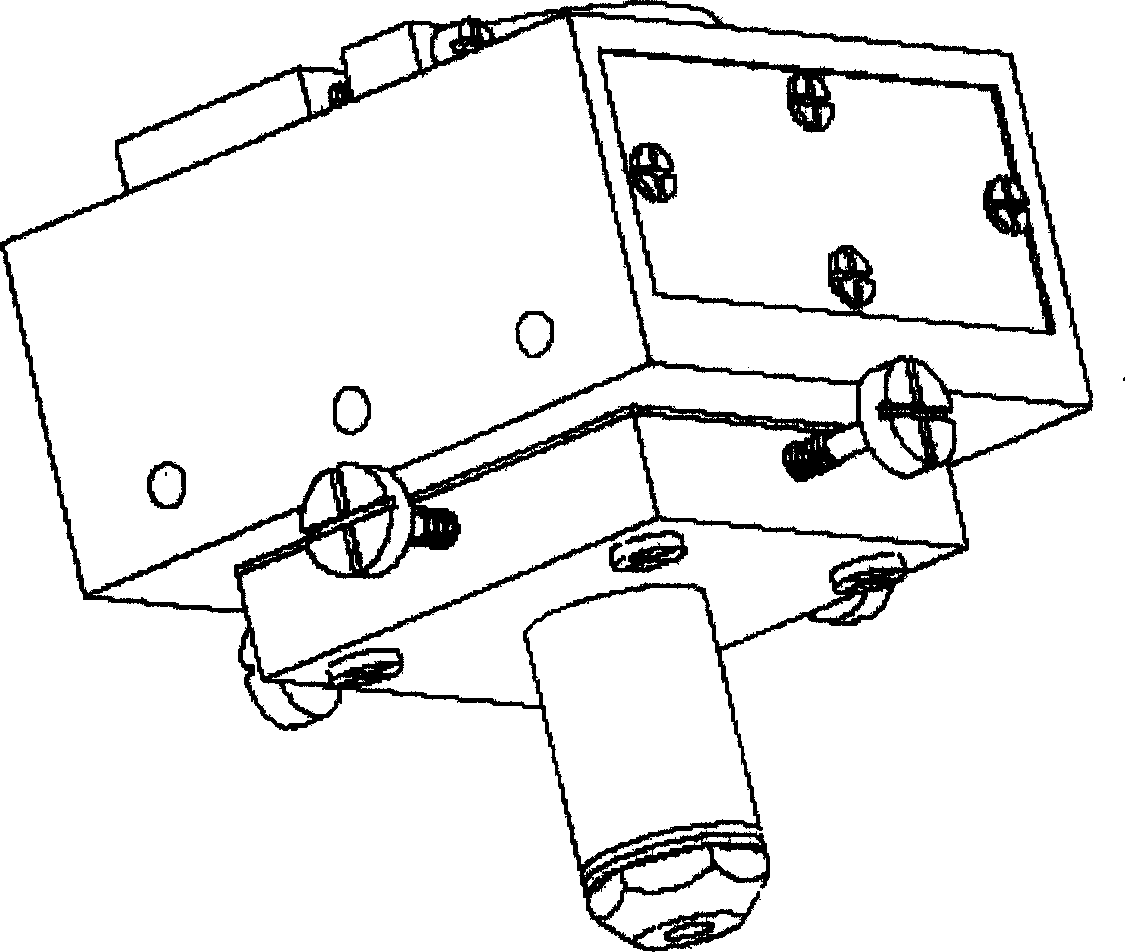

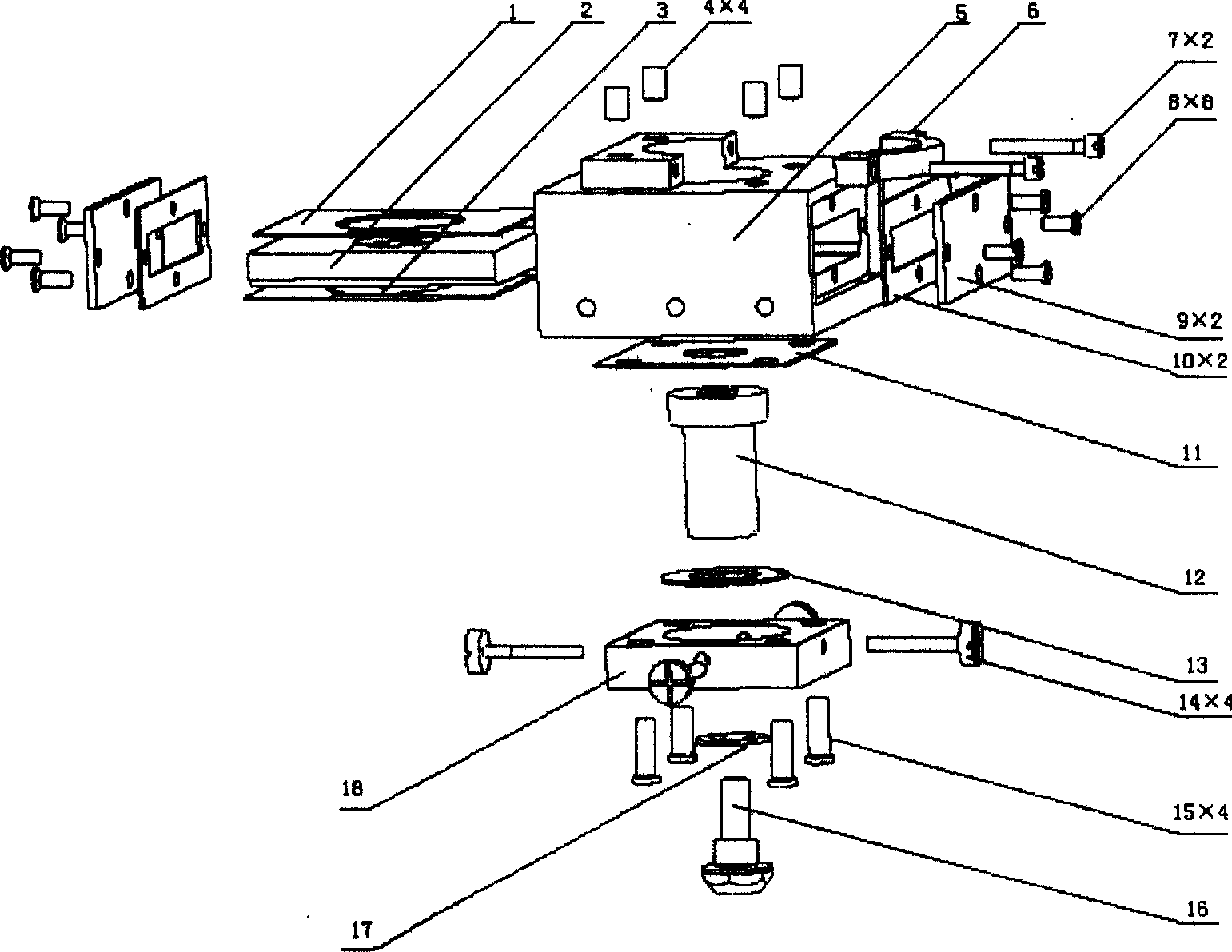

Laser cutting head

A laser cutting head, a new type of technology, used in laser welding equipment, welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 Newly designed cutting head equipped with supersonic nozzles for cutting galvanized sheets

[0042]The nozzle design Mach number is 1.5, the theoretical gas supply pressure is 4bar, the thickness of the galvanized sheet is 1mm, the cutting gas is nitrogen, the gas supply pressure is 5bar, and when the cutting speed is 4.8m / min, the cut end surface is very bright, and the galvanized layer is There is almost no damage at the incision, only 0.2mm wide remelted and solidified galvanized layer; there is no dross in the lower layer of the incision; the roughness of the incision end face is Ra=2.4812μm.

[0043] cutting speed

[0044] It can be seen from the above results that the laser cutting with the new continuous supersonic nozzle has fast cutting speed and good cutting quality. At the same time, when the distance from the nozzle to the upper surface of the workpiece is large, the cutting quality is still good, which is difficult for traditional laser ...

Embodiment 2

[0045] Example 2 Using high-pressure nitrogen to cut stainless steel

[0046] cutting speed

(m / min)

(mm)

Lower surface seam width

(mm)

Tilt angle

(°)

roughness

Ra(μm)

2.0

0.20

0.15

0.716

rare

3.1

2.5

0.19

0.13

0.859

No

1.7

3.0

0.18

0.12

0859

rare

2.8

[0047] The cutting quality of the above-mentioned groups of experiments is relatively good. The incision width on the upper and lower surfaces is small, and the inclination angle is also small, the verticality of the incision is high, the incision section is smooth, and the roughness Ra is small.

[0048] Cutting 5mm thick stainless steel plate, the brand is 304 (1Cr18ni9), the laser power is 2000W, the distance between the nozzle and the workpiece is 1.2mm, nitrogen is used as the cutting gas, the gas supply pressure is 8bar, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com