Process to separate colour bodies and/or asphalthenic contaminants from a hydrocarbon mixture

A hydrocarbon mixture, asphaltene technology, used in the separation of color bodies and/or asphaltene contaminants, to solve problems such as excessive coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

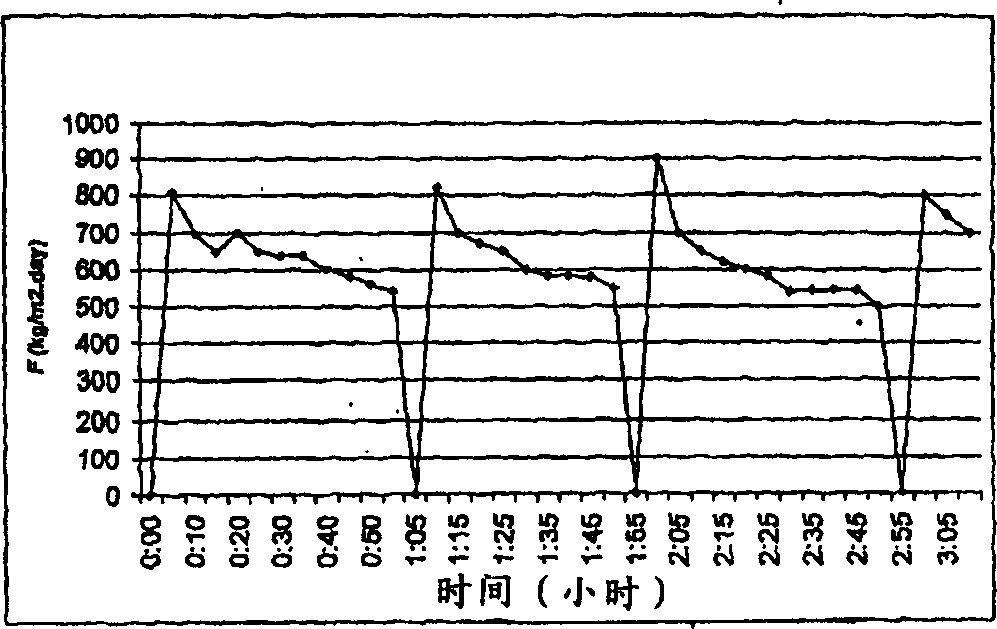

[0028] A black condensate with the characteristics shown in Table 1 was fed into the membrane separation unit at a flow rate of 70kg / h, where part of the retentate was recycled and mixed with fresh feedstock, so that the fluid flow rate on the feed side of the membrane was 1000kg / h. The membrane separation unit was equipped with a 1.5 m 2 A PDMS / PAN 150 membrane comprising a polydimethylsiloxane (PDMS) top layer and a polyacrylonitrile (PAN) support layer. At the time of separation, the differential pressure is 20 bar and the pressure on the permeate side is close to atmospheric pressure. The operating temperature was 70°C. The ASTM color of the permeate was 1.5.

[0029] The whole test time is 24h. Permeate flow was stopped by manually closing the valve in the permeate removal line for 5 minutes every approximately 55 minutes of normal separation time. During this time, the pressure on the permeate side was found to be close to the pressure on the feed side, within 1 bar....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com