Internal barrel water-discharging structure of water-saving wave wheel type or stirring type full-automatic washing machine

A fully automatic washing machine and pulsator-type technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., and can solve the problems of easy swelling, easy leakage, easy water leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

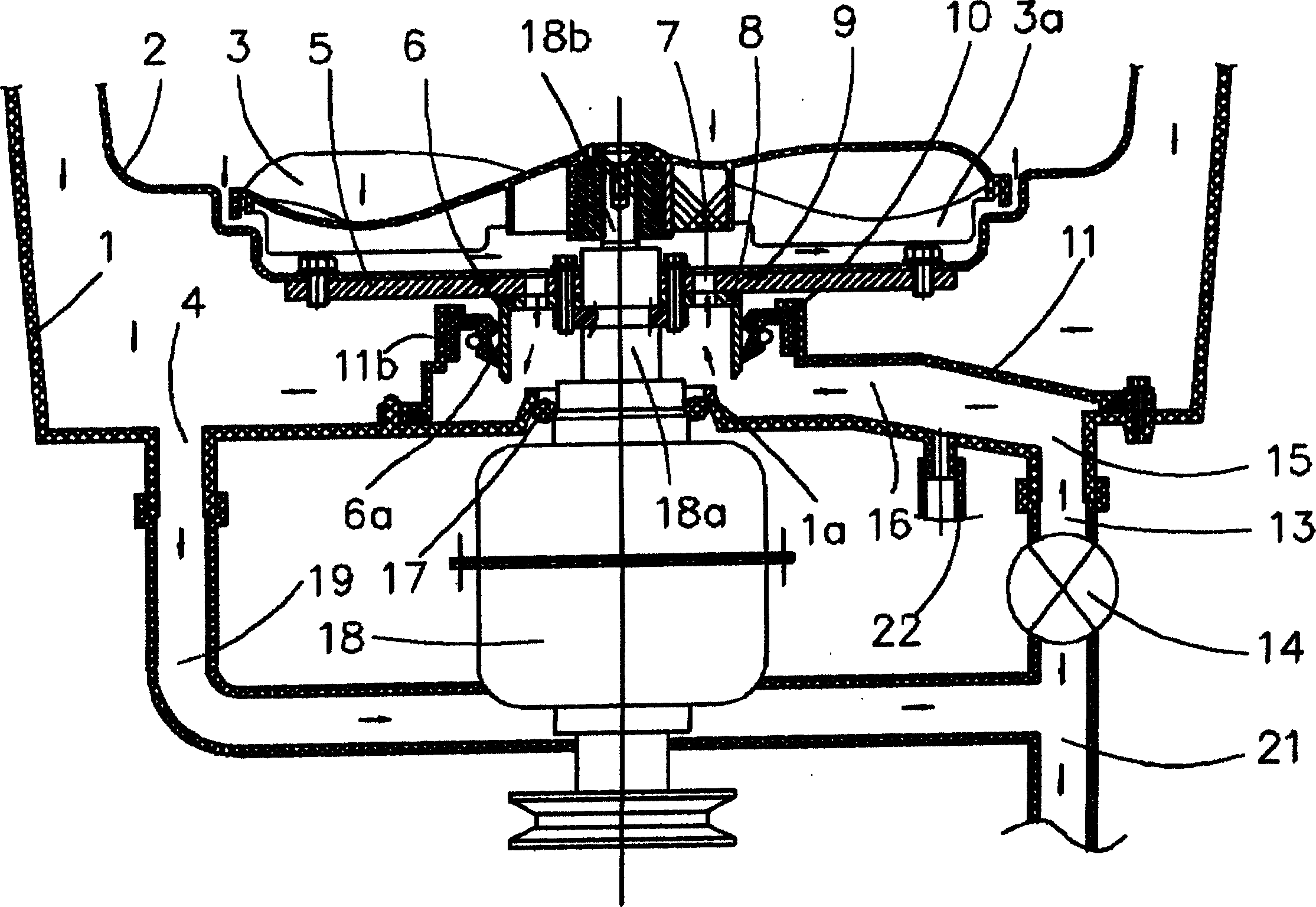

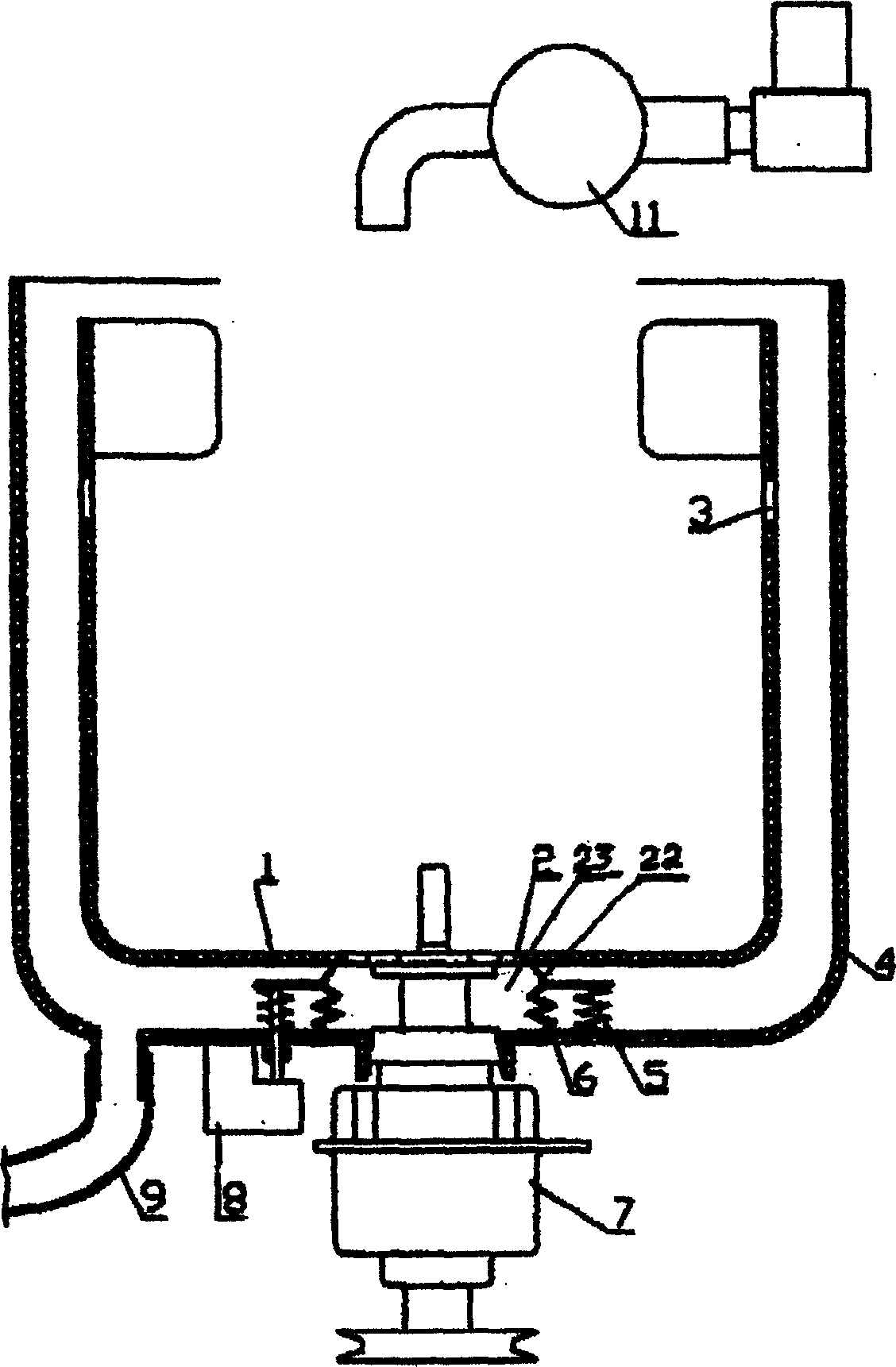

[0021] The structure of the drain valve in the washing machine in the first embodiment of the present invention is as follows: Figure 4 shown. This structure is improved on the basis of the pulsator type or agitator type fully automatic washing machine of the prior art, and the parts similar to the prior art include: the upper shell shaft fixing part of the deceleration clutch 017 driven by the motor through the pulley is covered with a sealing ring Fixed in the center hole of the outer barrel 005; the inner barrel 008 set in the outer barrel 005 is fixed on the dehydration shaft 015 through the tray, the inner barrel 008 has no holes in the side wall of the lower part, and there is a circle of dehydration outlet holes in the upper part and the bottom is distributed in the inner barrel 008 The axis of rotation is the drain hole 011 in the center of a ring; the dehydration shaft 015 also has a coaxial washing shaft 014 for connecting the pulsator 013. The main improved design...

no. 2 Embodiment

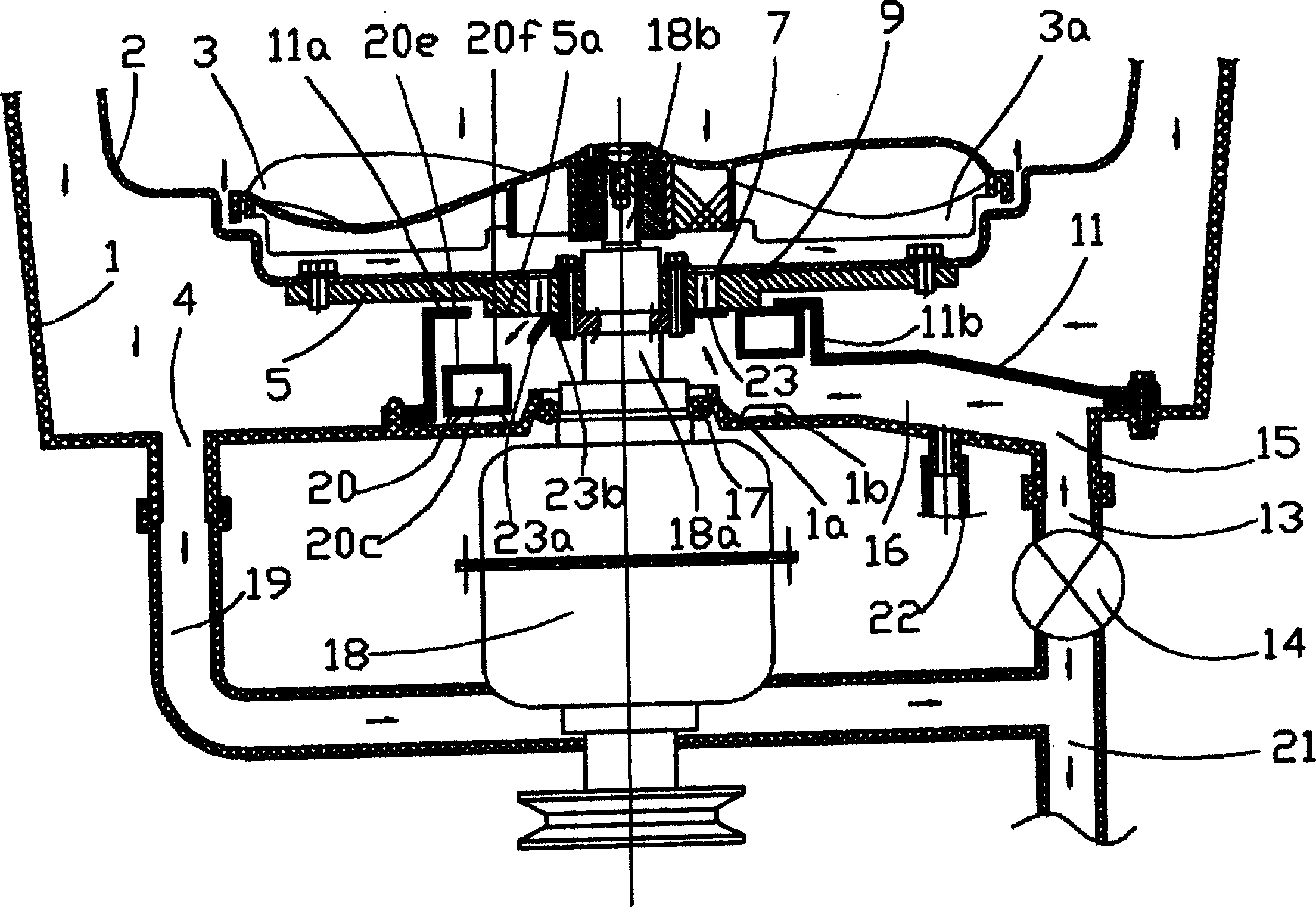

[0027] The structure of the drain valve in the washing machine in the second embodiment of the present invention is as follows: Figure 5 As shown (the meaning and function of the symbols in the figure not explained in the text are the same as Figure 4 the same). The structure is the same as Figure 4 The difference of the first embodiment shown is mainly that in the axial cam pair composed of the sealing plate 112 and the lifting boss ring 109 inserted around the cylinder of the tray, the driven teeth 119 are formed on the sealing plate 112 instead; and, The central part of the sealing plate 112 is changed to slide and rotate with the cylindrical surface, and the lifting boss ring 109 is fixed to the bottom of the outer barrel 105 instead of rotating. In this way, when the driven tooth 119 is driven by the main driving tooth 007, the sealing plate 112 rotates up and down around the cylindrical surface, separates and closes with the sealing ring 010, and produces the same c...

no. 3 Embodiment

[0029] In the third embodiment of the present invention, the structure of the drain valve in the inner tub of the washing machine is as follows: Figure 6 As shown (the meaning and function of the symbols in the figure not explained in the text are the same as Figure 4 the same). The structure is the same as Figure 4 The difference of the first embodiment shown is mainly: the clutch lever 201 of the deceleration clutch 217 is axially driven (as can be seen in the applicant's Chinese invention patent application "Automatic washing machine deceleration clutch", application number: 03140019.1), the clutch operation The rod 201 is linked with the driving rod 203 to push and pull the fork 206 to rotate around its fulcrum, and the fork 206 thus moves the sealing plate 212 inserted into the cylinder around the tray to directly lift and separate and close with the sealing ring 010 to produce the same control effect. Apparently, the sealing movement of this structure passing throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com