Dust collector rotary switch

A technology of knob switch and vacuum cleaner, which is applied in the direction of resistors, adjustable resistors, sliding contact resistors, etc., can solve the problems of separation of switch and adjustment functions, increase of product cost, and inconvenient operation, so as to achieve functional unity and reduce parts , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

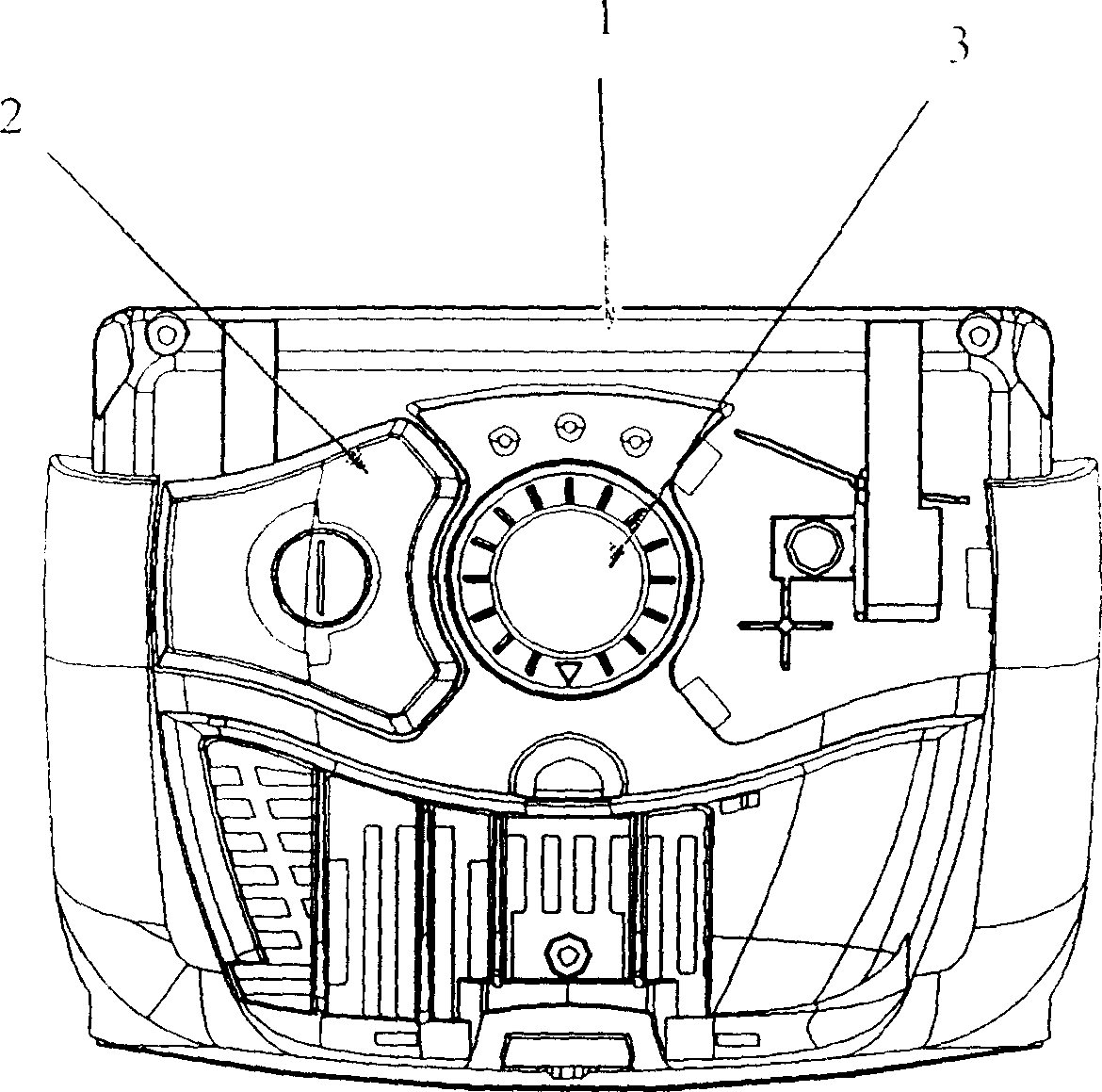

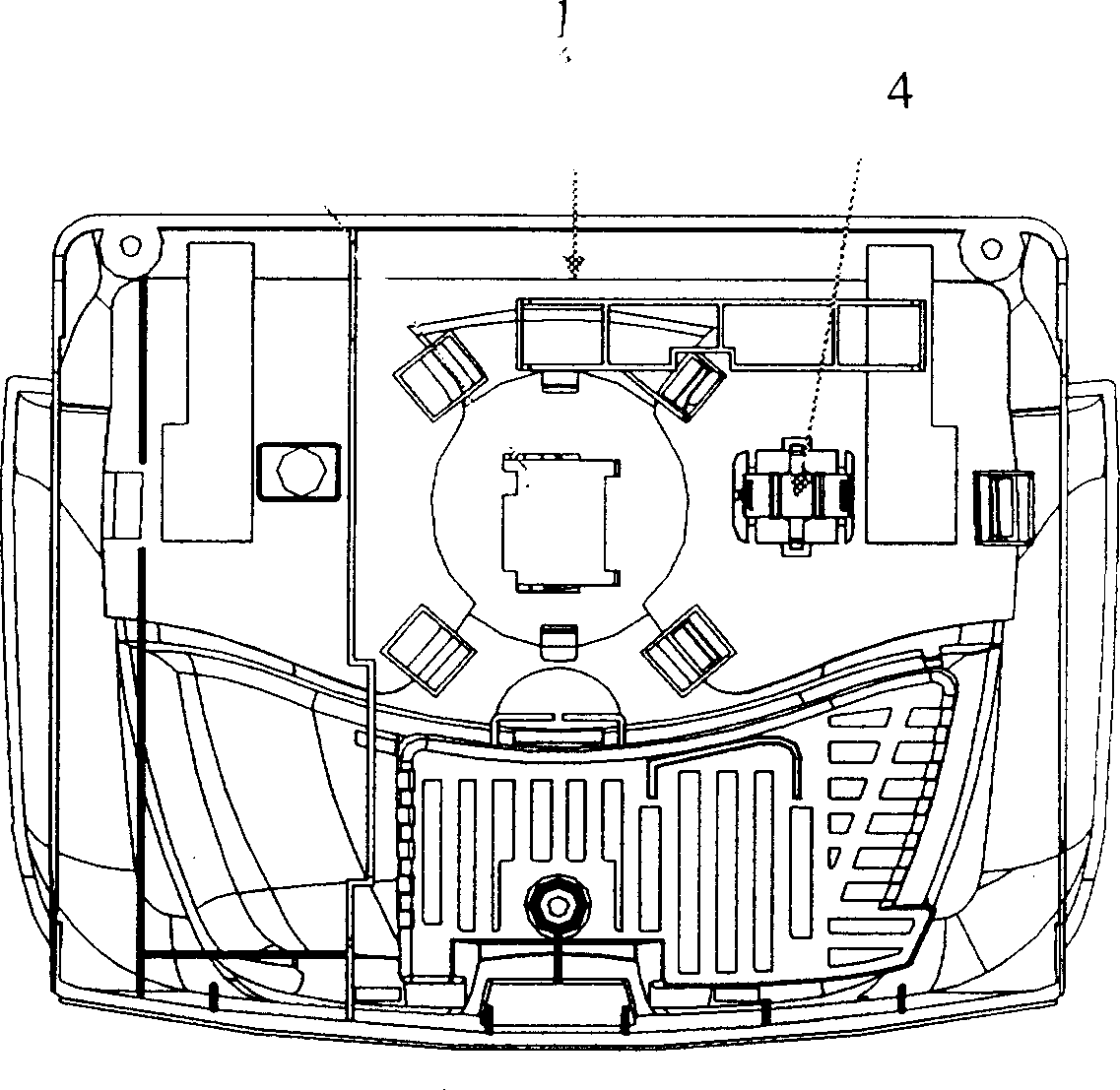

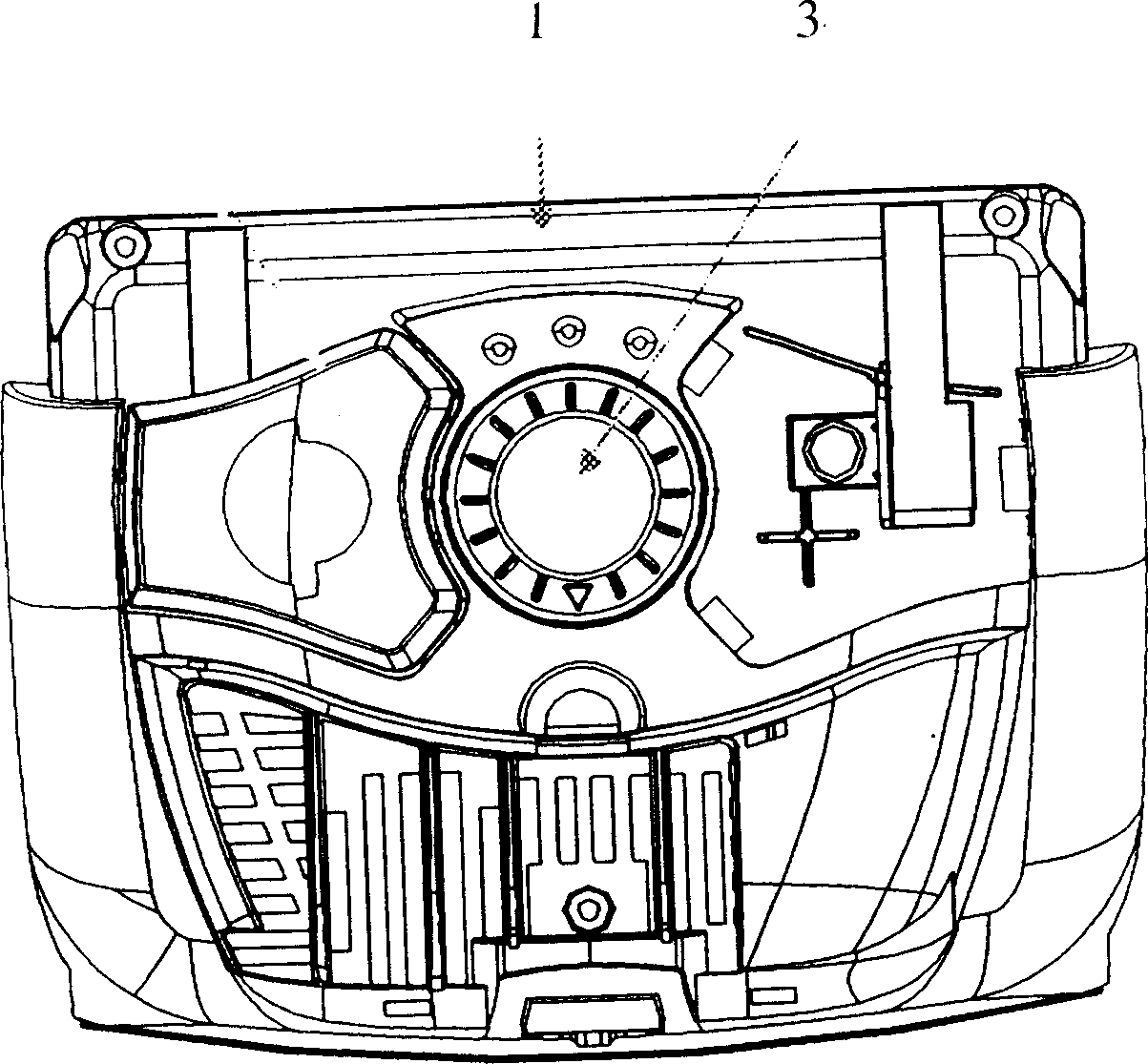

[0020] The specific embodiments of the present invention will now be described with reference to the drawings. Such as image 3 with Figure 4 As shown, the rotary switch of the vacuum cleaner according to the present invention is arranged on the upper cover 1 of the body of the vacuum cleaner, and is composed of a rotary dial 4 and a PWB (sliding varistor). The knob plate is connected to the power switch, PWB (sliding varistor) and the cable reel, and the PWB is connected to the control circuit of the fan motor.

[0021] In application, turn the knob of the knob switch, turn on the power switch, and then continue to turn the knob of the knob switch, and adjust the speed of the vacuum cleaner fan motor through the PWB to adjust the suction rate of the vacuum cleaner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com