Water source heat pump water heater

A water source heat pump and water heater technology, applied in fluid heaters, lighting and heating equipment, etc., can solve problems such as energy inefficiency, electric shock hazards, air leakage, heat energy loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

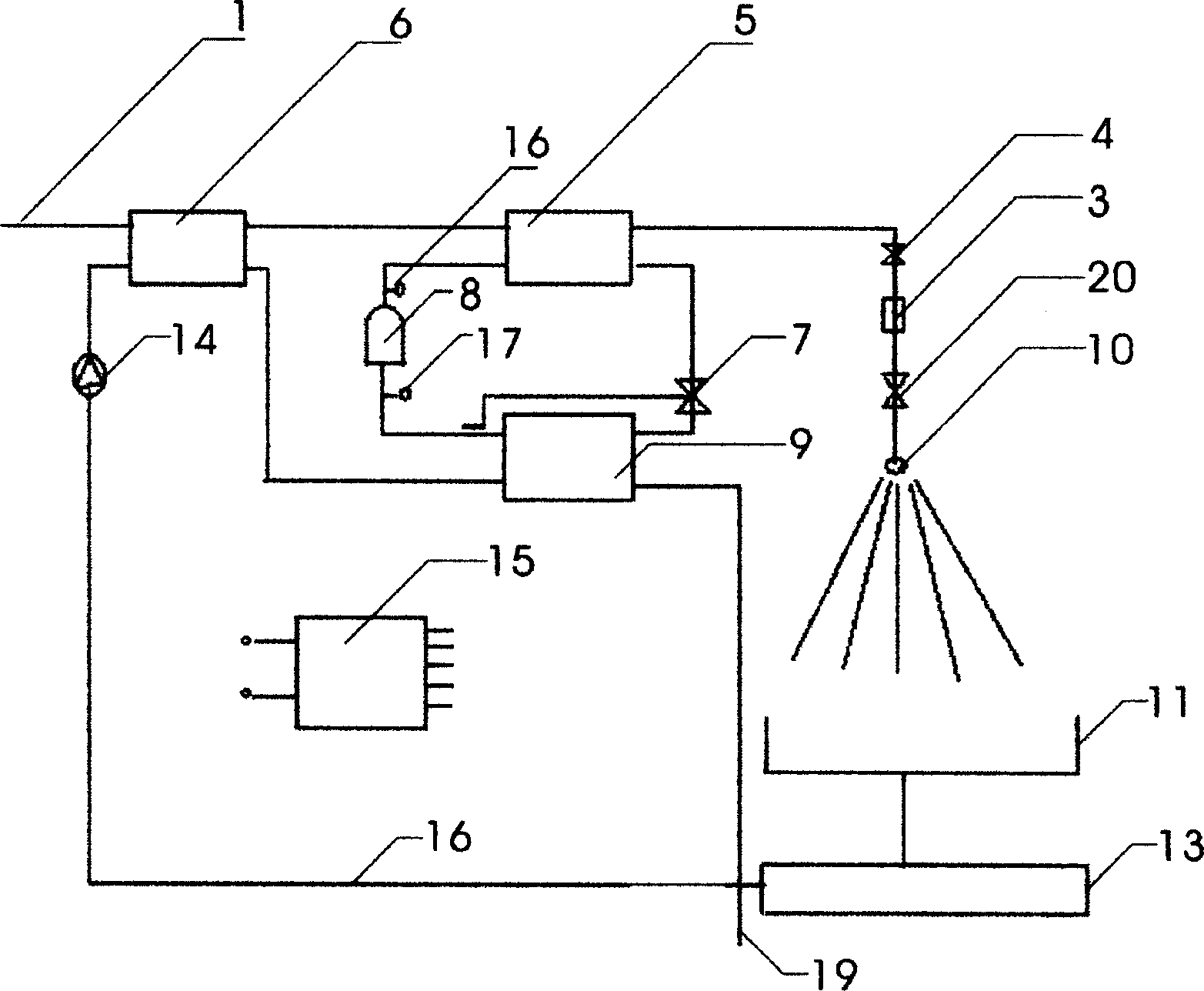

[0014] As shown in the figure, the figures indicate: compressor 8, tap water inlet pipe 1, hot water outlet pipe 10, water basin 11, waste water filter 13, return water pipe 18, return water pump 14, electric control box 15, heat exchange 5, heat exchanger 6, heat exchanger 9, high pressure protection switch 16, low pressure protection switch 17, throttle valve 7, water outlet switch 20, water flow switch 3, constant temperature water outlet switch 4, waste water filter 12, return pipe 18, Backwater pump 14, waste water outlet 19.

[0015] The present invention mainly comprises water-water heat exchanger, water-working medium heat exchanger, working medium-water heat exchanger, compressor, constant temperature water outlet valve, microcomputer control box, water collection basin, and is characterized in that: the compressor , tap water inlet pipe, hot water outlet pipe, water basin, waste water filter, return pipe, return water pump, electric control box, heat exchanger, heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com