Solid-insulated closing assembly for high-voltage alternating-current vacuum switch cabinet

A technology of vacuum switch and solid insulation, which is applied in high-voltage/high-current switch, high-voltage air circuit breaker, switchgear setting, etc. It can solve the problems of poor safety, potential safety hazard, large volume and weight, etc., and achieve convenient connection and use Safety, the effect of reducing the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

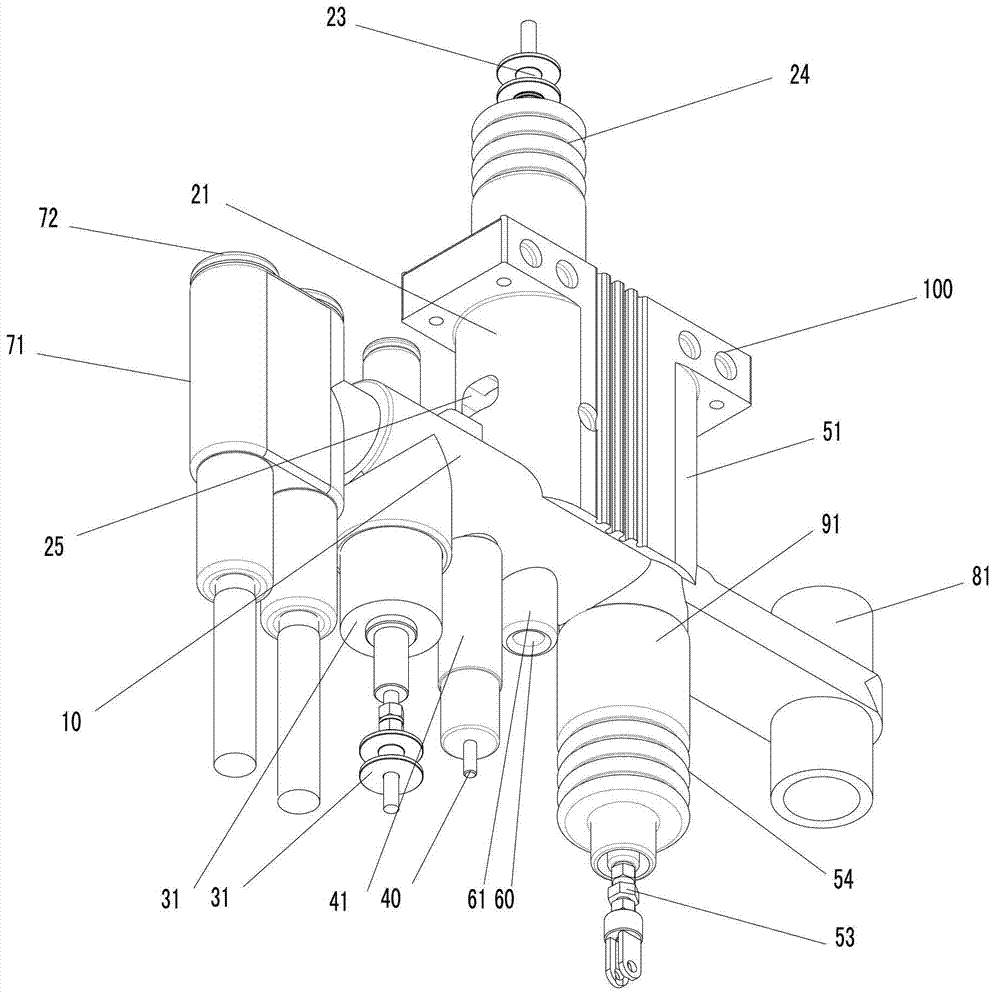

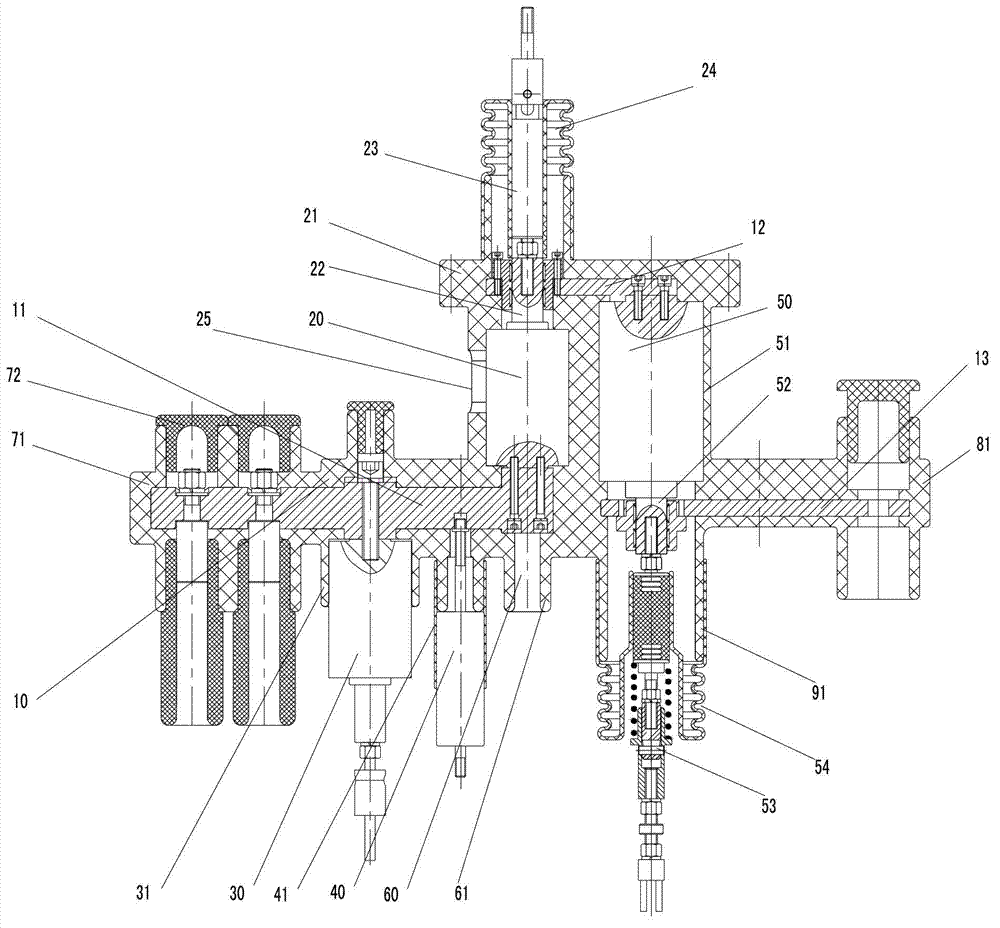

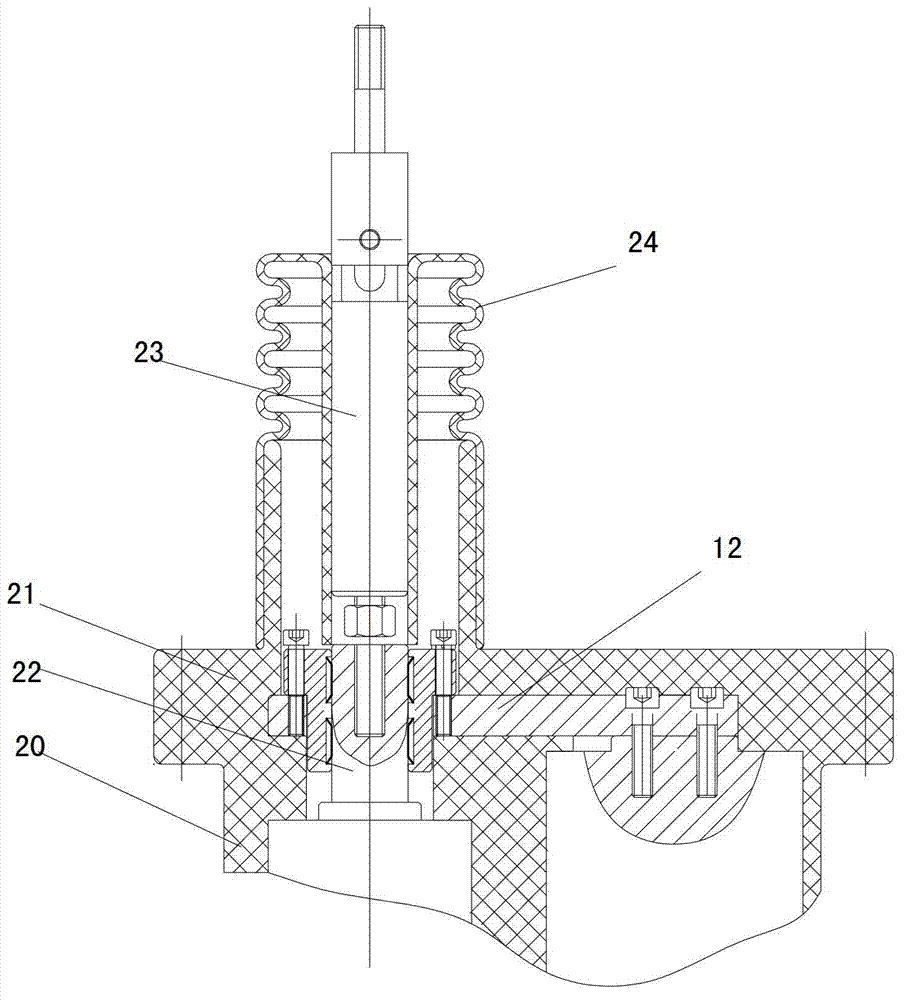

[0029] refer to figure 1 and figure 2 , the solid insulation closure assembly for high-voltage AC vacuum switchgear of the present invention includes a solid-sealed spine 10 and a vacuum circuit breaker 50 sealed in the solid-sealed spine 10, a vacuum disconnector 20, a vacuum grounding switch 30, a lightning arrester 40, The connection socket 60 of the voltage transformer and the horizontal special-shaped conductive rod 11 , the first conductive plate 12 and the second conductive plate 13 . The solid-sealed spine 10 is made of insulating materials including soft solid insulating materials in the inner layer and hard insulating materials in the outer layer. The solid-sealed spine 10 is provided with a mounting bracket 100 to be installed in a unit cabinet.

[0030] A first end seat 51 and a second end seat 21 located on the left side of the first end seat 51 are provided upwards in the middle of the embossed spine 10 , and a third end seat 91 extends downward from the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com