Sensing system of fiber strain

A technology of sensing system and optical fiber strain, which is applied in the direction of using optical devices to transmit sensing components, using optical devices, measuring devices, etc., can solve problems such as failure to work normally, excessive signal attenuation, and being affected by temperature, and achieve anti-electromagnetic Strong interference ability, small influence of humidity changes, stable and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

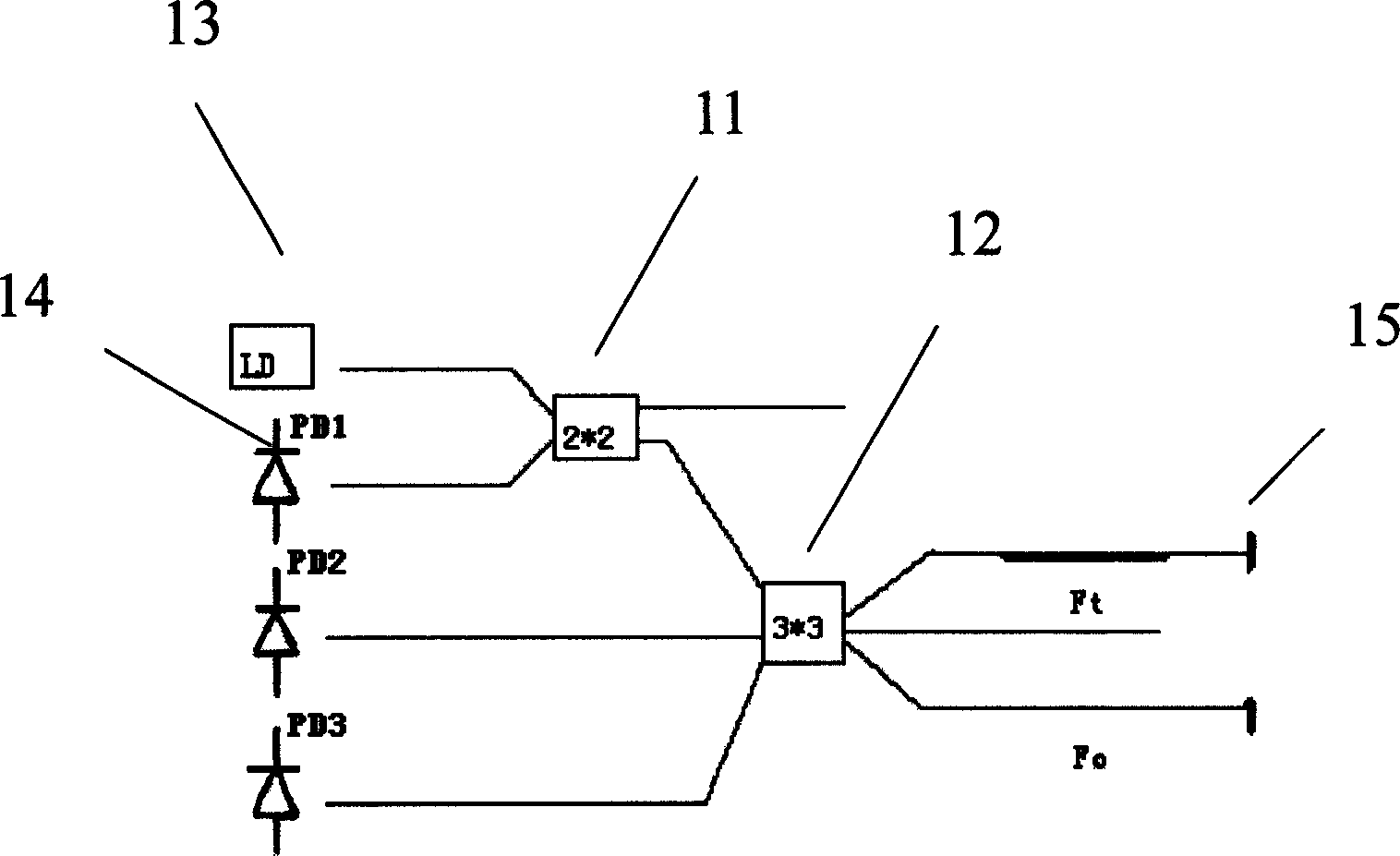

Method used

Image

Examples

specific Embodiment 1

[0022] In order to simulate the stressed state of the bridge to test the effectiveness of the optical fiber strain sensing system of the present invention, we made a set of test experimental device-equal strength cantilever beam. The material is 65Mn steel, and its elastic modulus E is measured to be 200.5Gpa.

[0023] The width b of the consolidated end of the equal-strength cantilever beam is 72mm, the thickness h is 6mm, and the length l is 350mm. Let the hanging weight P be W = b h 2 6 = 36 × 6 2 6 = 432 m m 3 1kg, then:

[0024] Section modulus:

[0025] Bending distance: M=Pl=9.8×1×350=3430N-mm

[0026] Theoretical stress: σ = ...

specific Embodiment 2

[0035] Temperature condition experiment: place the small cantilever beam pasted with the optical fiber strain sensor of the present invention in the experiment box, after the temperature of the experiment box reaches the calibrated temperature and stabilizes, take it out and immediately carry out the loading experiment and record the data.

[0036] Humidity condition experiment: place the optical fiber strain sensor of the present invention in the concrete curing room and set the temperature and humidity to make it stable, and record data at the same time.

[0037] The measured data of high-temperature and low-temperature cantilever beam loading experiments are as follows:

[0038] temperature(℃)

[0039] Optical fiber strain sensor humidity measured data table of the present invention

[0040] time (minutes)

[0041] Experiments show that the optical fiber strain sensor of the invention can adapt to the temperature environment of -50°C to 90°C and the applic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com