Device for producing a predetermined orientation

A technology of action and direction of movement, applied in the direction of transportation and packaging, circuits, electrical components, etc., can solve the problem of reducing the efficiency of the feeding system, and achieve the effect of reliable orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

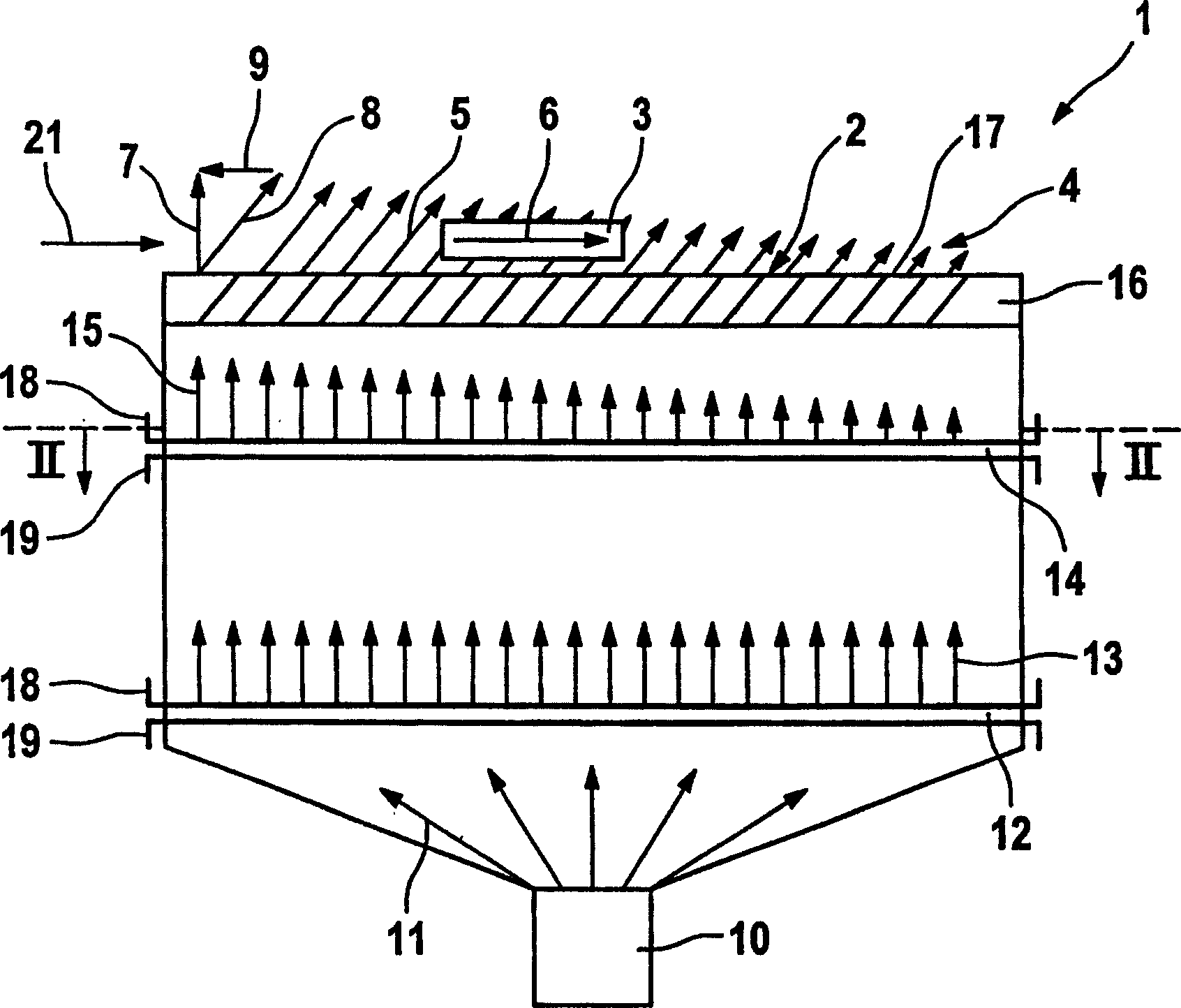

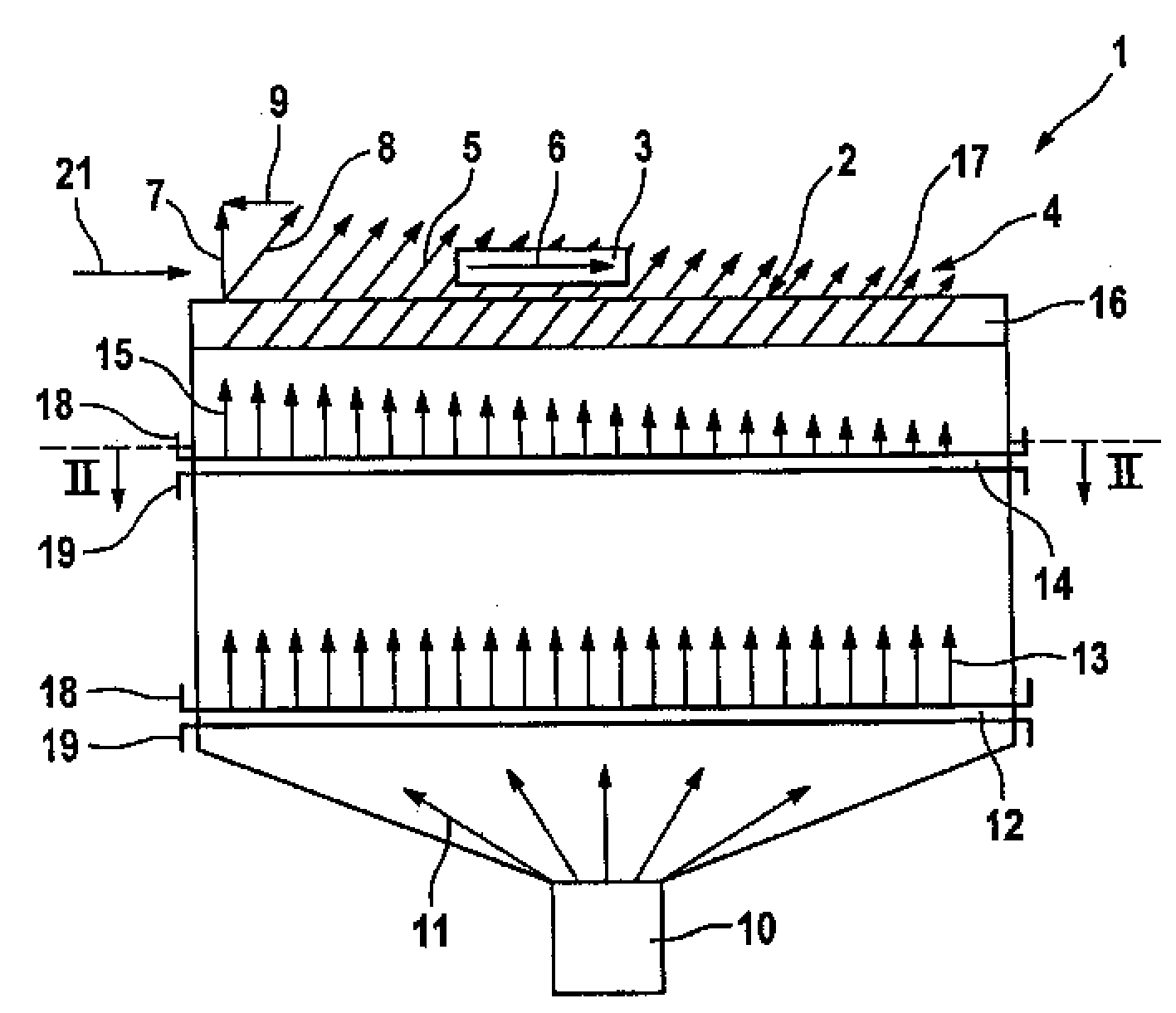

[0022] figure 1 A schematic diagram of a device 1 for positioning a workpiece 3 transported onto a sliding surface 2 by means of an air flow 4 designed as an air cushion is shown. The air flow 4 has an effective direction 5 arranged obliquely to the direction of movement 6 of the workpiece 3 , so that the air flow 7 resulting from the acting air flow 8 and the air flow 9 generated by the movement of the workpiece is arranged perpendicular to the direction of movement 6 of the workpiece 3 . In this case, the air flow 9 generated by the movement of the workpiece corresponds to the aerodynamic resistance of the workpiece 3 and thus opposes the direction of movement 6 of the workpiece 3 . In addition, a further air flow 21 can act on the workpiece 3 , which is directed in the direction of movement 6 of the workpiece 3 .

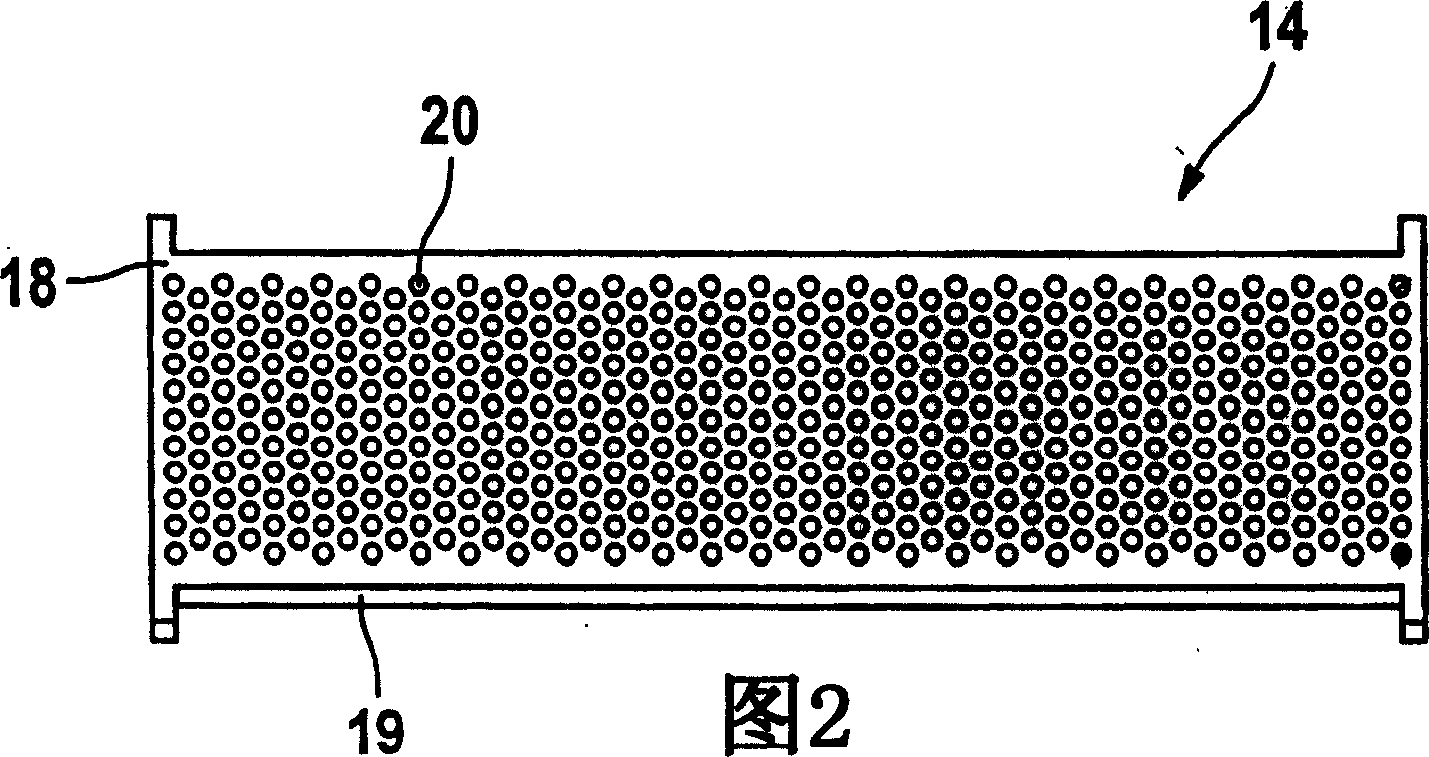

[0023] The blowing air 11 generated by the blower 10 is leveled by means of the first jet element 12 , so that a uniform flow field 13 is produced, which is ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com