Clamping device

A kind of clamping equipment and clamping technology, applied in the direction of metal processing equipment, instruments, manufacturing tools, etc., can solve the problems affecting the repeatability of measurement, etc., and achieve the effect of high balance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

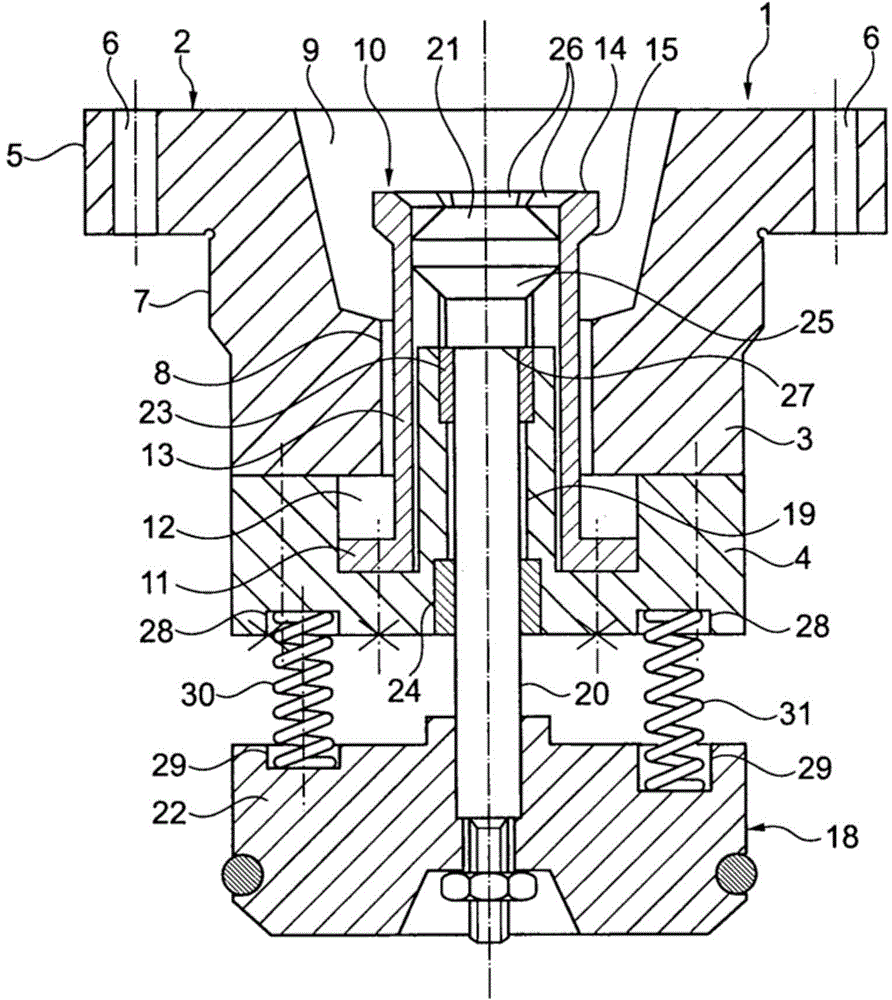

[0018] The illustrated clamping device 1 is inserted into the open end of the hollow main shaft of the balancing machine for this purpose. The clamping device 1 has a receiving unit 2 composed of two parts connected to each other by a screw connection, a receiving part 3 and a supporting part 4. A flange 5 with a fixing bore 6 on the receiving part 3 is used to fix the receiving unit 2 on the end face of the hollow spindle. In order to accurately center the hollow spindle, the receiving part 3 is provided with a centering surface 7 on its outer side. A through hole 8 extends axially through the accommodating part 3, which leads to a central accommodating opening 9, which is designed to accommodate a standardized hollow bevel clutch shaft of a tool. Of course, the accommodating part 3 can also be constructed, and the accommodating part 3 also has a differently designed accommodating opening for accommodating a clutch shaft of another shape.

[0019] In the through hole 8 there i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com