Method and bearing for balancing rotors without journals

A technology of supporting devices and rotors, applied in static/dynamic balance testing, measuring devices, testing of machine/structural components, etc., can solve problems such as inaccurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

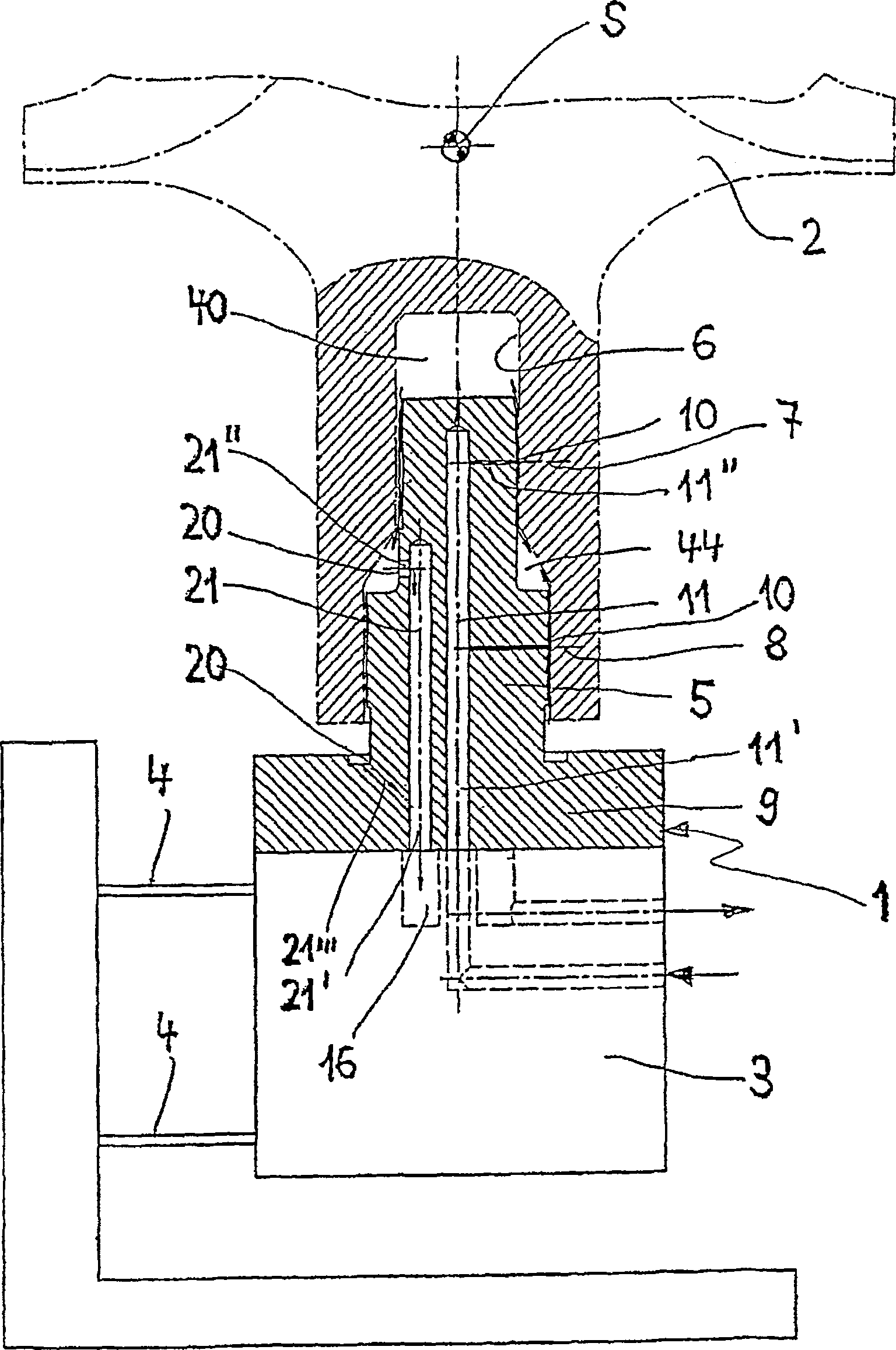

[0015] figure 1 Indicated for a rotor 2 to be checked (in figure 1 Indicated by dotted lines) the supporting device 1 is fixed on a balance bridge 3 of a balancing machine. The bearing device 1 has a bearing mandrel 5 on which the rotor 2 to be checked or balanced is rotatably mounted. The balancing bridge 3 is normally supported vibratingly on the balancing machine frame by means of, for example, four support springs 4, only two of which are shown in the figure. The rotor 2 is driven in rotation by a drive not shown further here. The unbalance-induced vibrations of the bearing spindle or balancing bridge 3 are measured and used to determine the degree of unbalance on the rotor 2 to be balanced.

[0016] The rotor 2 has a closed central rotor bore 6 , ie a blind bore, by means of which the bearing on the vertically arranged bearing mandrel 5 takes place. The center of gravity S of the rotor lies axially outside the length dimension of the blind bore, ie outside the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com