Decompression dry device and method

A decompression drying device and drying technology, applied in optics, instruments, optomechanical equipment, etc., can solve problems such as long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

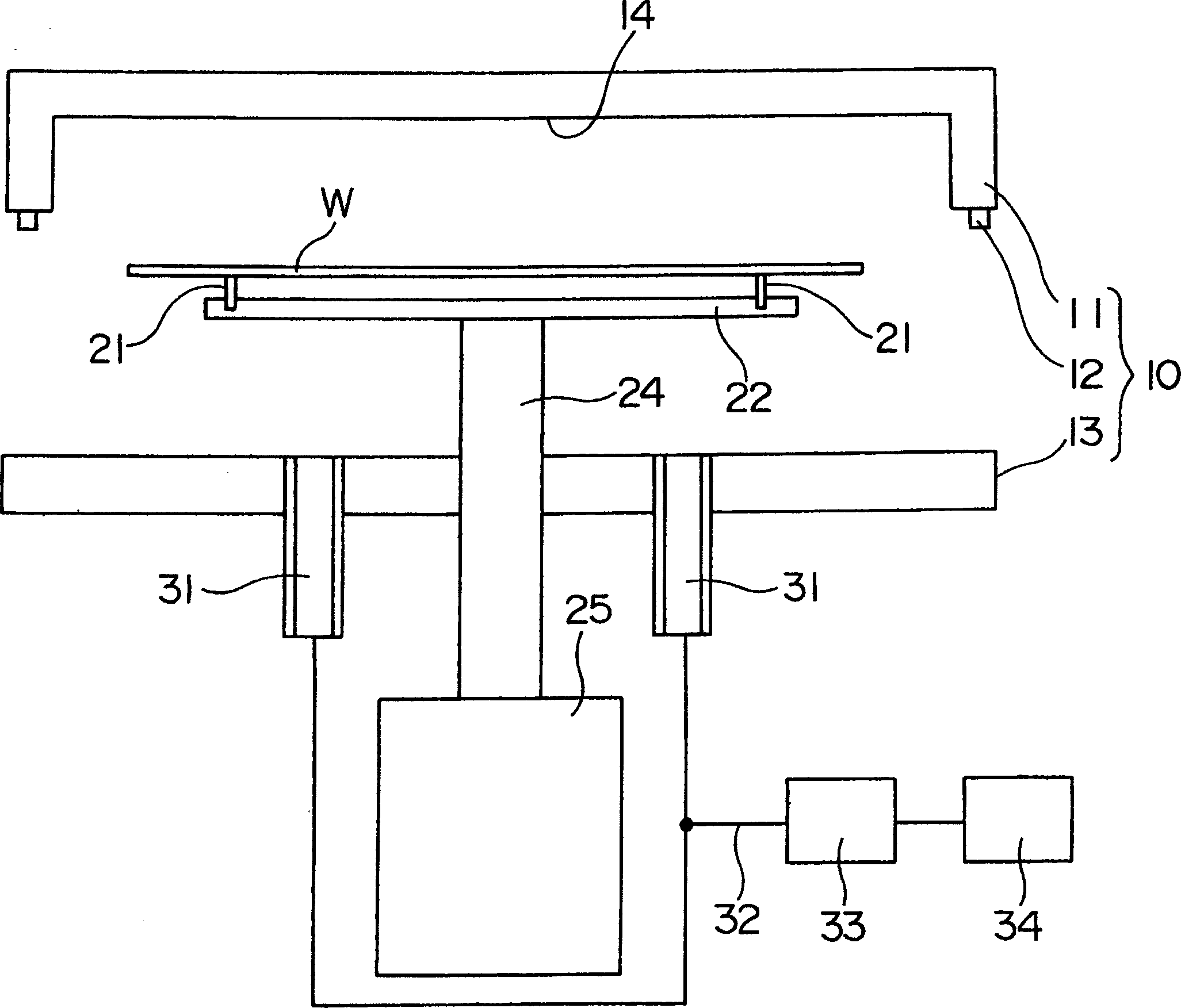

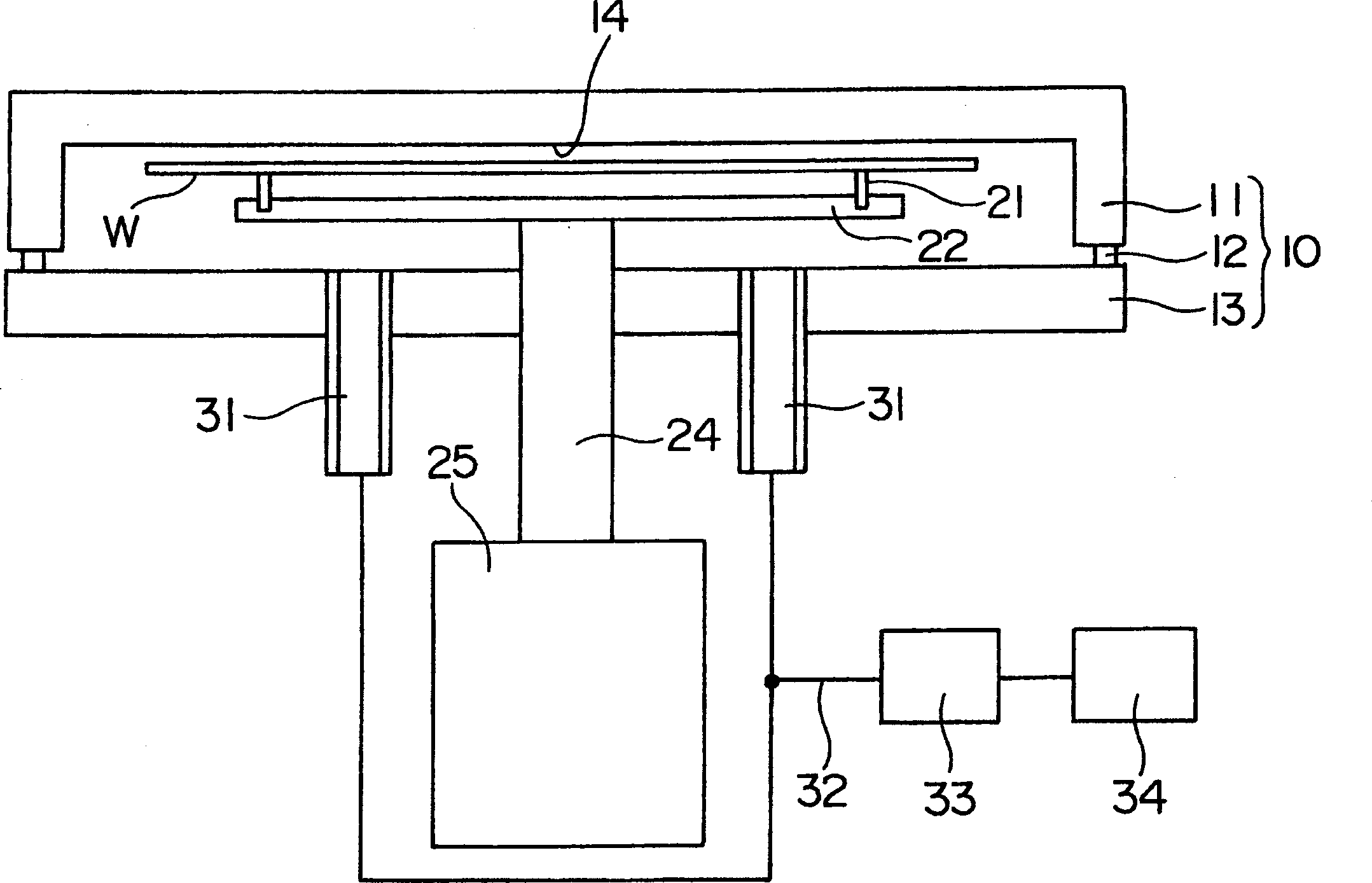

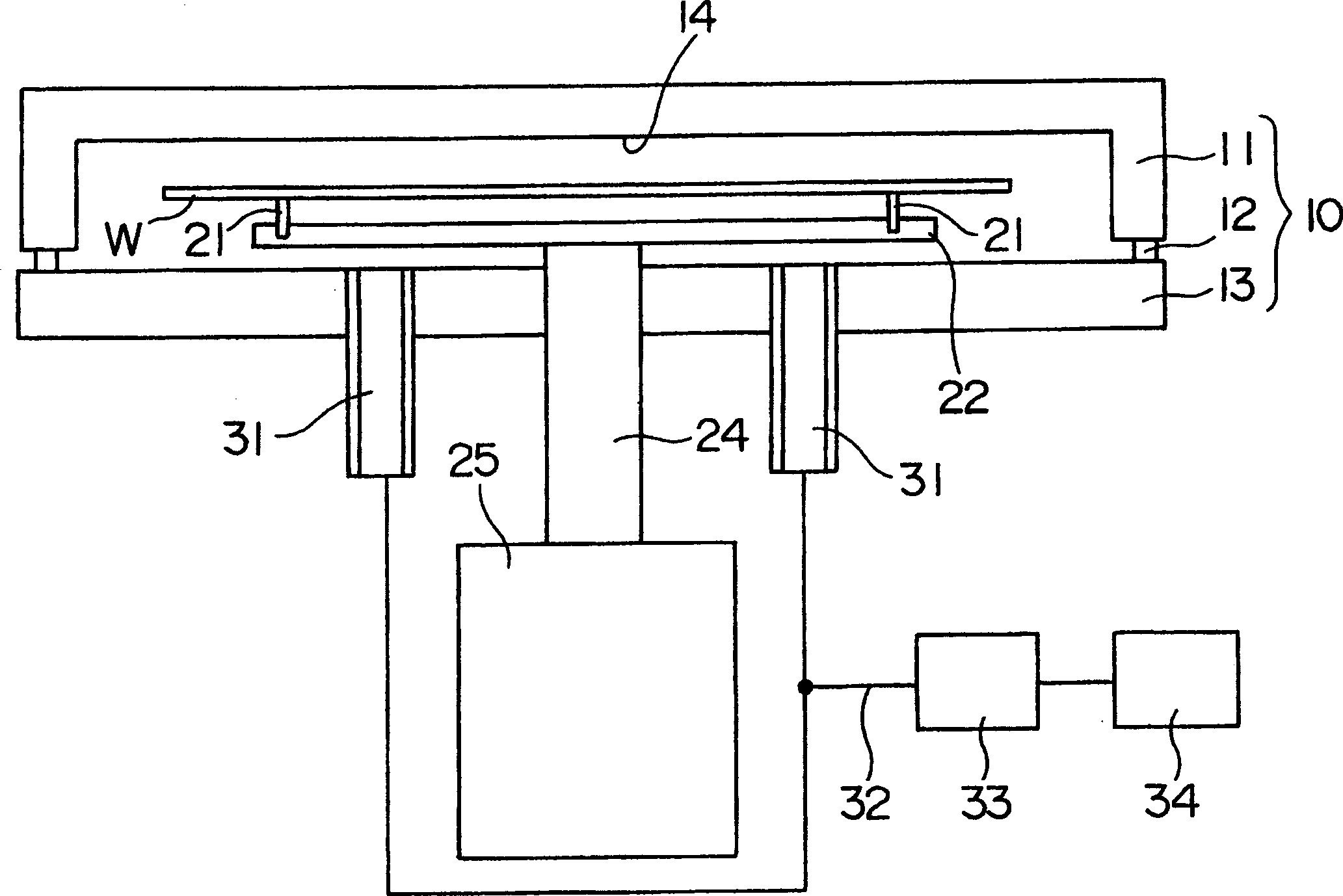

[0027] Hereinafter, embodiments of the present invention will be described based on the drawings. Figure 1 to Figure 3 It is a schematic diagram of the reduced-pressure drying apparatus concerning 1st Embodiment of this invention.

[0028] This reduced-pressure drying apparatus has a chamber 10 constituted by a lid 11 , a seal 12 , and a base 13 , and a support plate 22 on which support pins 21 for supporting a substrate W are erected. The substrate W is supported by support pins 21 in the chamber 10 in a horizontal posture with its main surface facing upward.

[0029] In the base 13 of the chamber 10, an exhaust port 31 is formed. The exhaust port 31 is connected to a vacuum pump 34 through a pipeline 32 . Furthermore, between the exhaust port 31 and the vacuum pump 34 , a damper 33 capable of controlling the amount of exhaust gas from the exhaust port 31 in two stages is arranged. In addition, an exhaust fan or the like may be used instead of the vacuum pump 34 . In add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com