Fuel filter arrangement

A technology of fuel filter and fuel oil, which is applied in the direction of membrane filter, filtration separation, charging system, etc., and can solve the problem of inability to use fuel oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

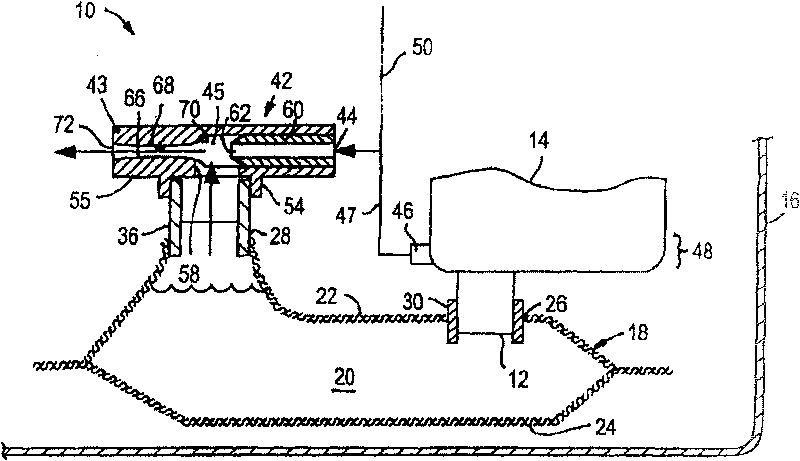

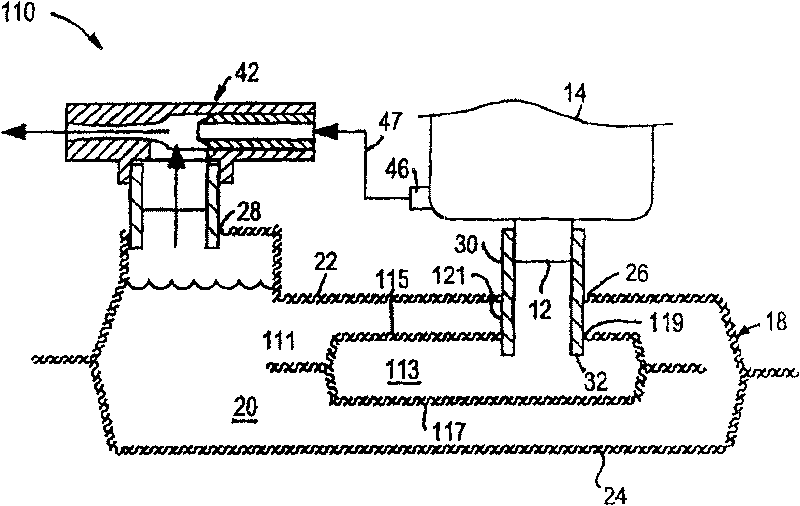

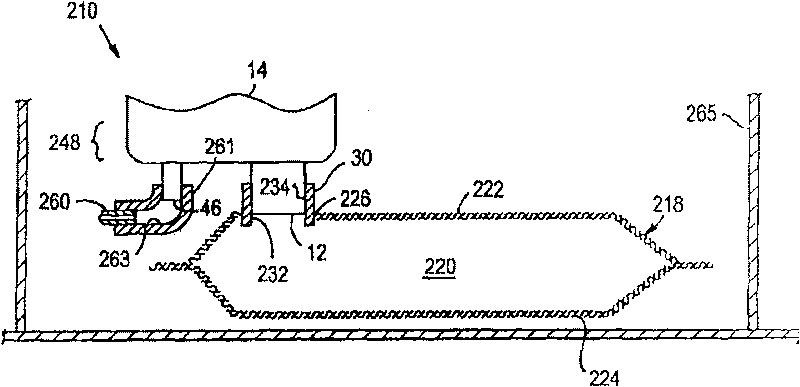

[0021] Referring to these drawings in detail, figure 1 There is shown a fuel filter assembly 10 constructed in accordance with a presently preferred embodiment of the invention, adapted to be connected to an inlet 12 of a high pressure fuel pump 14 preferably driven by an electric motor and disposed in a fuel tank 16 . The filter arrangement 10 facilitates the removal of fuel vapors from liquid fuel near the inlet 12 of the fuel pump 14 . Therefore, the fuel pump 14 can efficiently pump liquid fuel to the vehicle's engine (not shown), thereby maximizing the performance of the vehicle's engine and fuel pump.

[0022] still come to see figure 1 The filter device 10 has at least one layer of liquid fuel permeable material, hereinafter referred to as an outer layer 18 of permeable material, which forms a substantially closed cavity 20 . The outer layer 18 is preferably defined by a pair of walls, hereinafter referred to as upper wall 22 and lower wall 24 , which are sealed toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com