Organic light emitting display and method of fabricating the same

A light-emitting display, organic technology, applied in semiconductor/solid-state device manufacturing, electroluminescent light source, light source, etc., can solve the problems of reducing transfer efficiency, reducing OLED luminous efficiency, shortening OLED life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described more fully below with reference to the accompanying drawings, in which the preferred embodiments of the present invention are shown. However, the present invention may be implemented in different forms and should not be construed as being limited by the illustrated embodiments. The same reference numerals indicate the same elements throughout the specification.

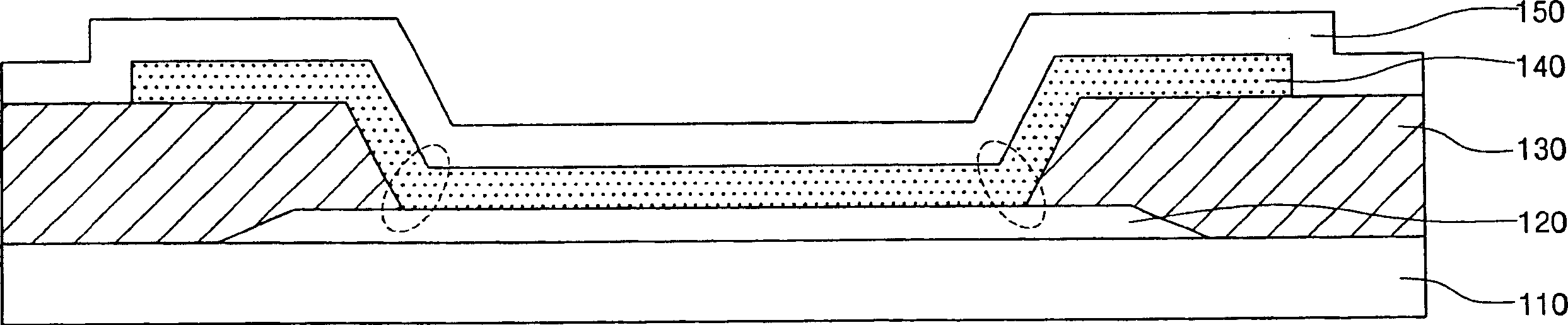

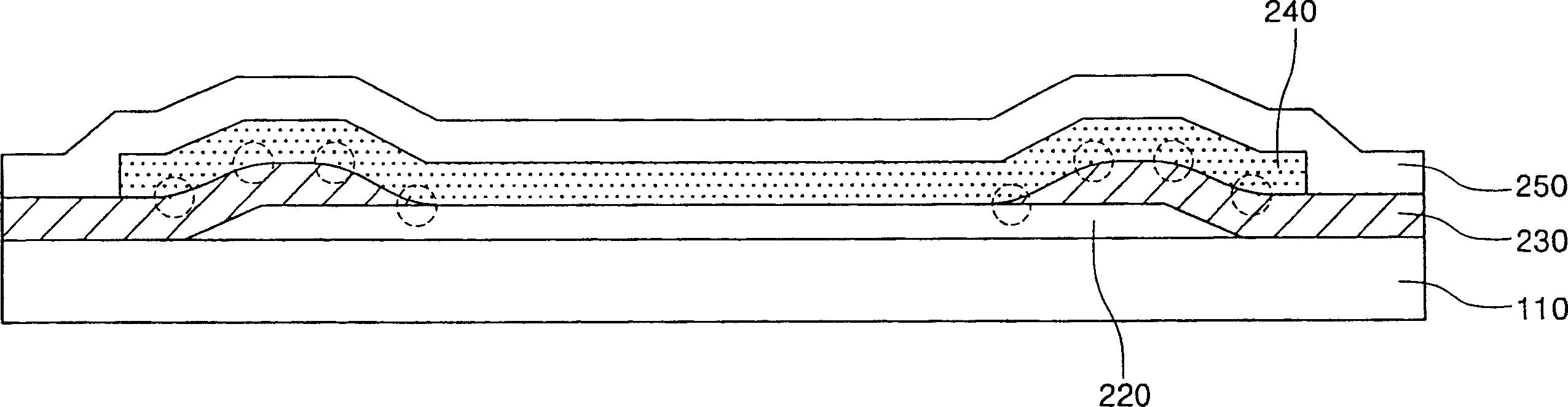

[0025] figure 2 It is a cross-sectional view of the OLED according to the present invention.

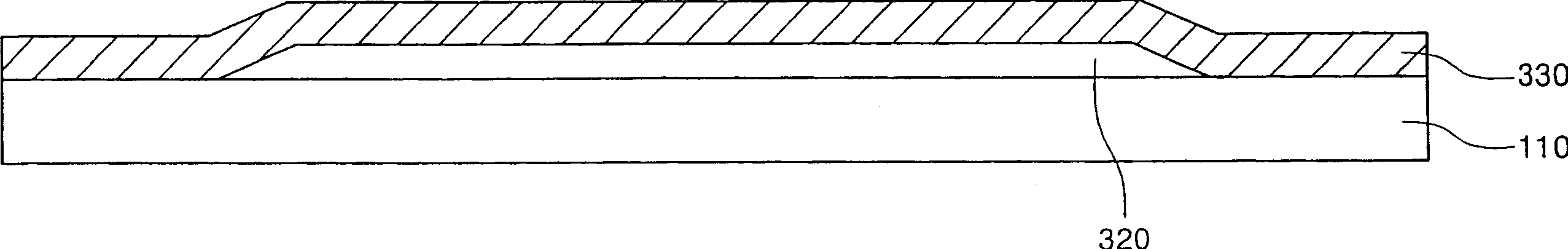

[0026] Reference figure 2 , A predetermined element is formed on the substrate 110, and the first electrode 220 is patterned and formed on the substrate 110. The substrate 110 may use a transparent insulating substrate, such as glass, plastic, and quartz.

[0027] When the first electrode 220 is an anode, the first electrode may be a transparent electrode made of ITO or IZO with a high work function, or a reflective electrode with a reflective layer as a lower layer, and the refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com