Funnel spinning device with funnel and sinning part

A funnel and driving device technology, applied in spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of fabric fiber pollution, ability destruction of telescopic movement, complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

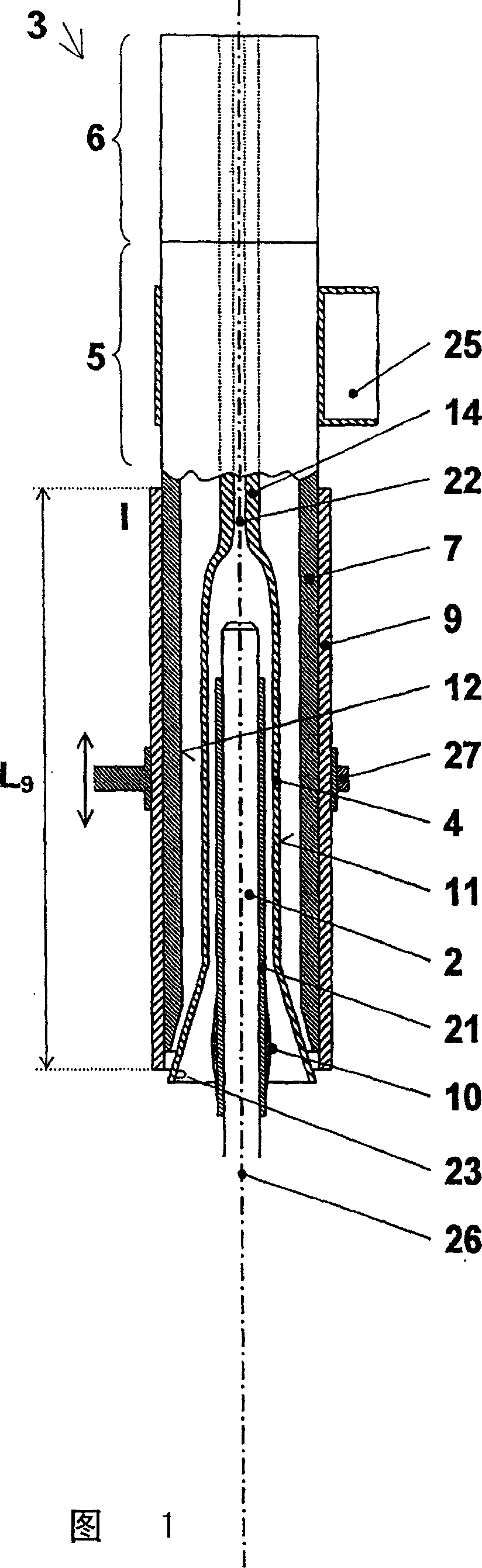

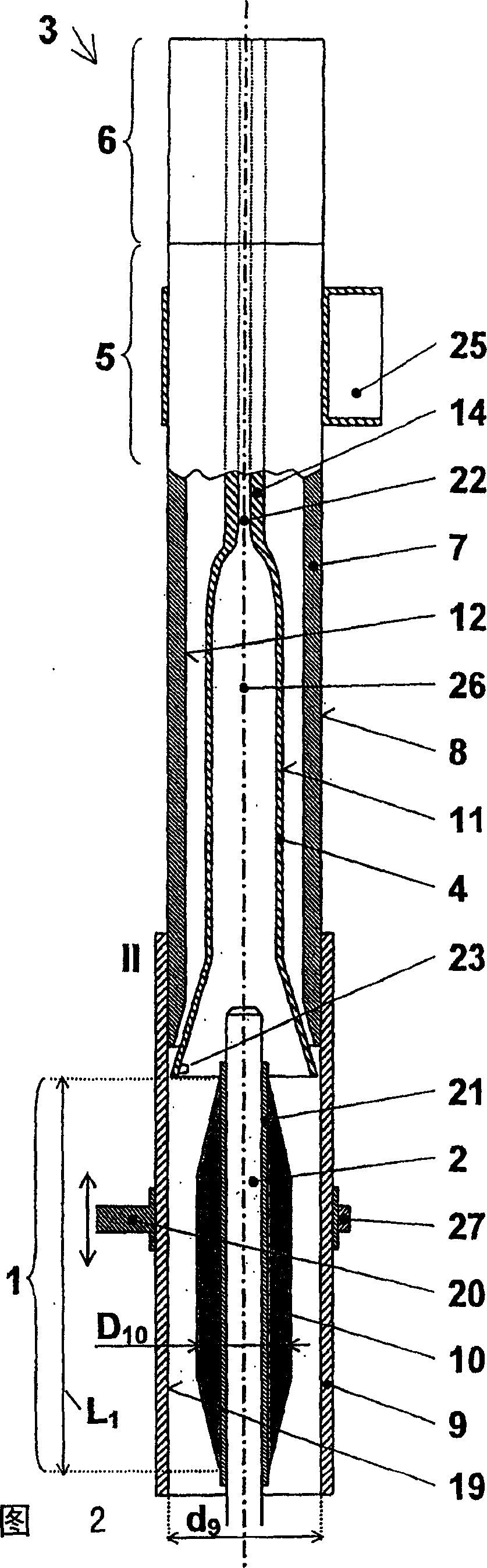

[0018]1 and 2 show a possible embodiment of a funnel spinning device comprising a spindle 2 and a funnel device 3 . The spindle 2 is driven about a spindle axis 26 by a single drive (not shown) and has a winding zone 1 for winding the yarn. For example, a winding zone 1 of length L1 is formed by the outer surface of the spindle 2 which is at least partially wound by the ready-to-wind yarn in the form of a bobbin 10 , as shown in FIG. 2 . In the example shown, the yarn is wound on a bobbin tube 21 placed on the spindle 2 . The package 10 comprising the wound yarn here constitutes the bobbin. The funnel device 3 also has a funnel 4 which is rotatable about the spindle axis 26 and has a cylindrical basic shape with a conically enlarged end. Furthermore, it is particularly possible to design the entire funnel 4 cylindrically or conically or to give the funnel 4 any other suitable shape in order to carry out the spinning method. The funnel 4 is rotatably fixedly connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com