Electronic weighing system for loading machine and method for metering loading capacity

A weighing system and loader technology, applied in loading/unloading, weighing, special scales, etc., can solve the problems of low measurement accuracy and poor reliability, and achieve scientific measurement methods, convenient use and maintenance, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

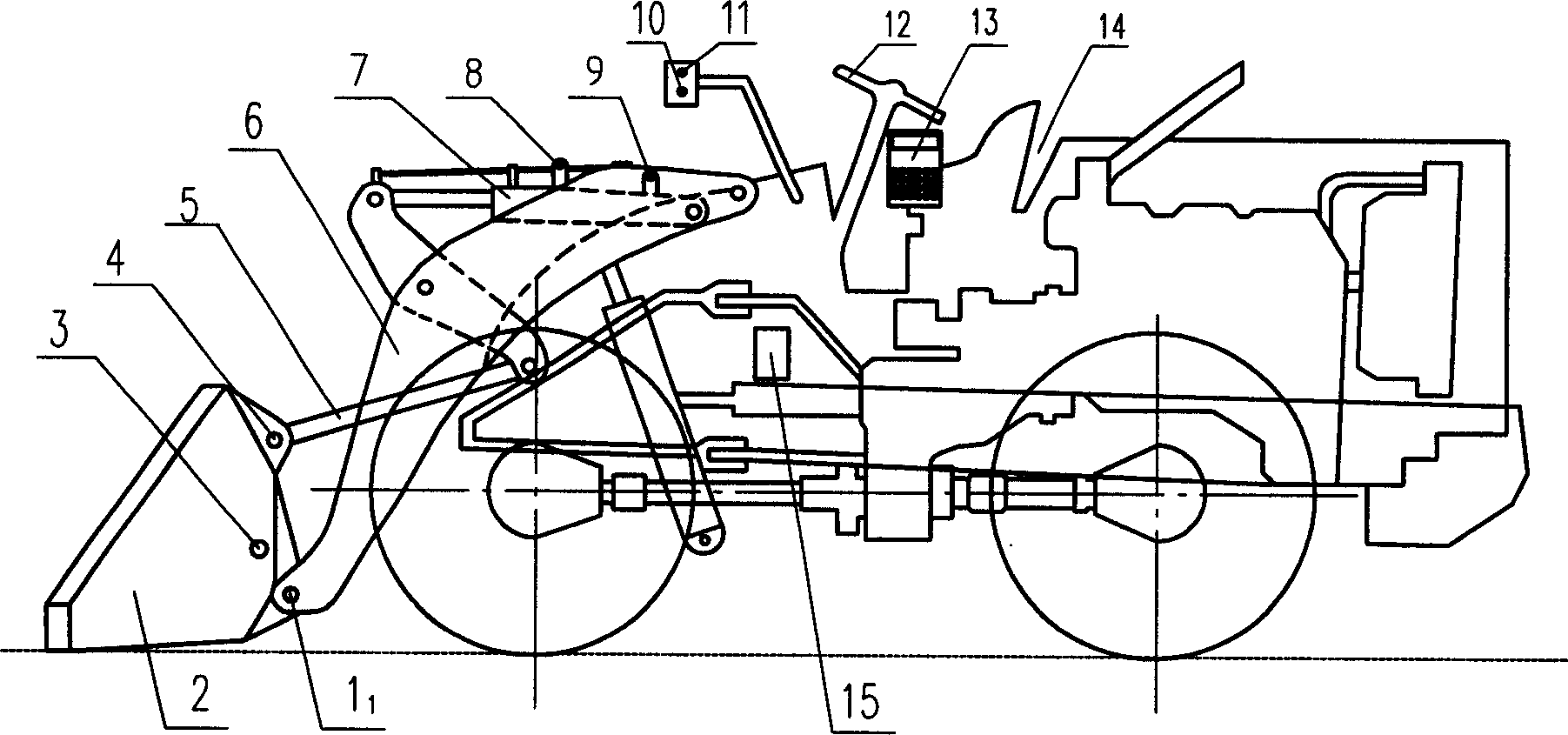

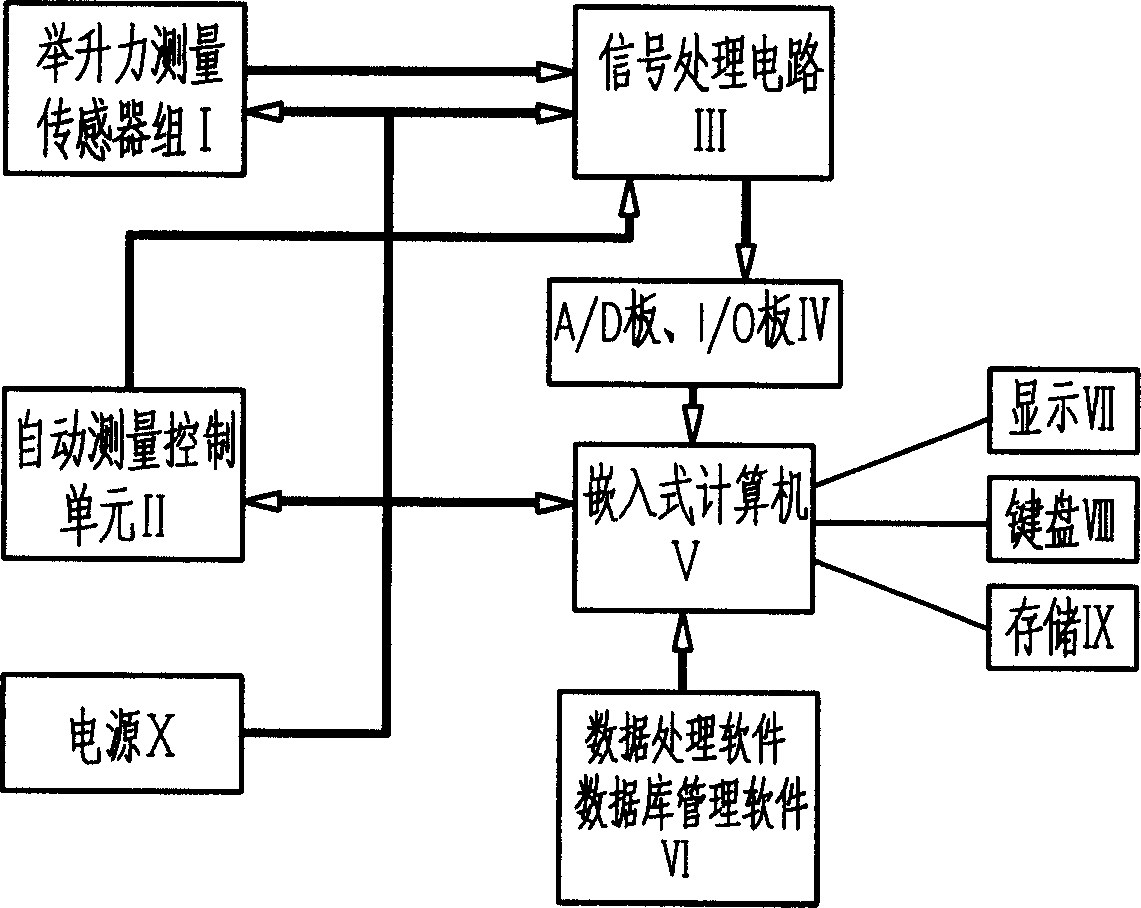

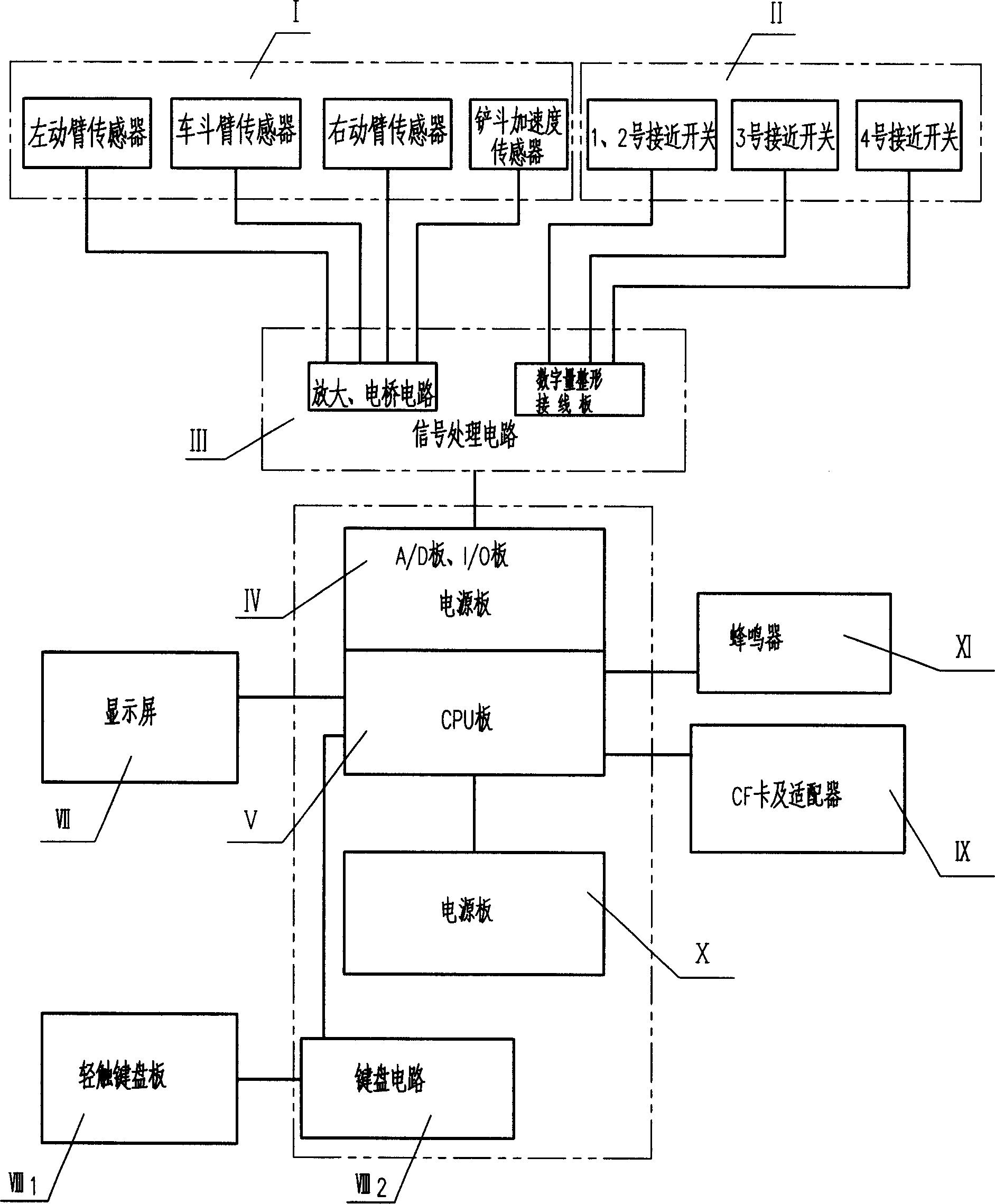

Embodiment 1

[0041]A loader electronic scale weighing system. The system includes a sensor group, an automatic measurement control unit, a signal processing circuit, a computer and a processing system, and a power supply X. The sensor group is the lifting force measurement sensor group I, and the automatic measurement control unit II is a bucket position measurement switch. group, the computer and processing system is an embedded computer V with weighing software and loading quality information management system software VI, the lifting force measurement sensor group I consists of pins installed at the junction of the bucket 2 and the left and right lifting arms The left and right lifting arm sensors 11, 12 on the shaft (not shown in the figure 12), the bucket acceleration sensor 3 installed on any position of the loader bucket 2, installed on the pin shaft at the junction of the bucket and the turning arm The flip arm sensor 4 is composed of the flip arm sensor 4. The automatic measuremen...

Embodiment 2

[0044] The method of measuring the load capacity of the loader by using the loader electronic weighing system described in Embodiment 1, the method measures the quality of the material in the bucket by measuring the lifting force of the loader bucket, that is: between the bucket 2 and Install the left and right lift arm sensor 1 on the pin shaft at the junction of the left and right lift arms 1 ,1 2 , the bucket acceleration sensor 3 is installed on the loader bucket 2, and the turning arm sensor 4 is installed on the pin shaft at the junction of the bucket and the turning arm to form the lifting force measurement sensor group I, and its data is input into the signal processing circuit III, and the signal The signal amplified and filtered by the processing circuit III is input to the embedded computer V through A / D data conversion, and then the weight of the material scooped by the loader bucket is calculated by the computer according to the relationship between the lifting fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com