Integrated assembling free flexible coupling

An assembly-free, coupling technology, which is applied in the field of mechanical parts, can solve the problems of short service life of couplings, easy wear and tear of elastic sleeves, etc. It has little influence on ambient temperature, convenient installation and disassembly, and long service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

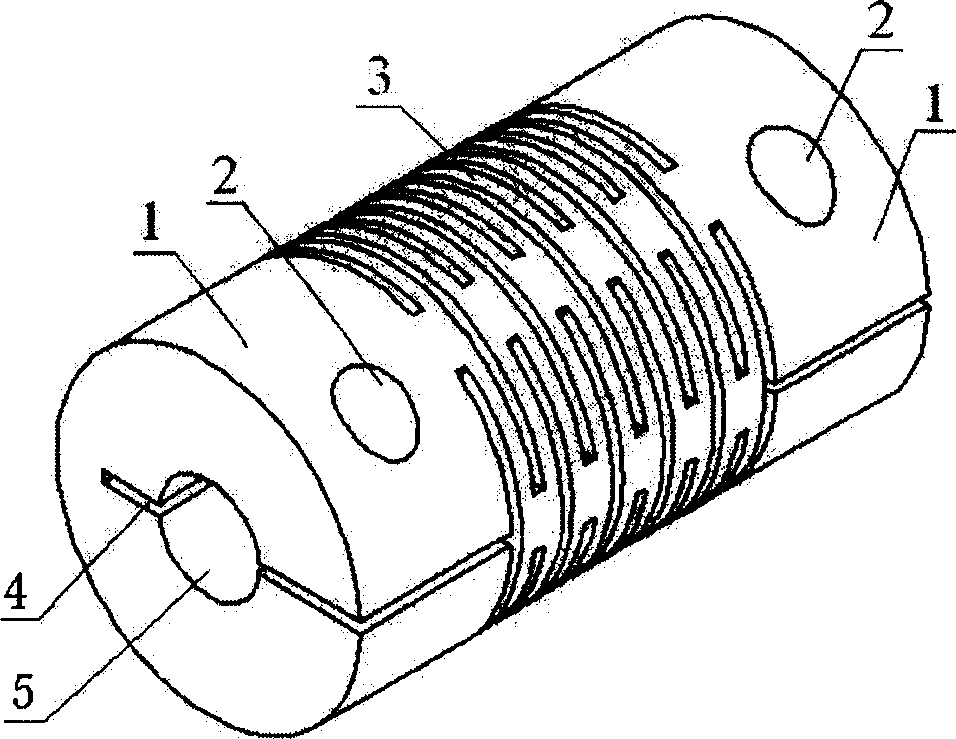

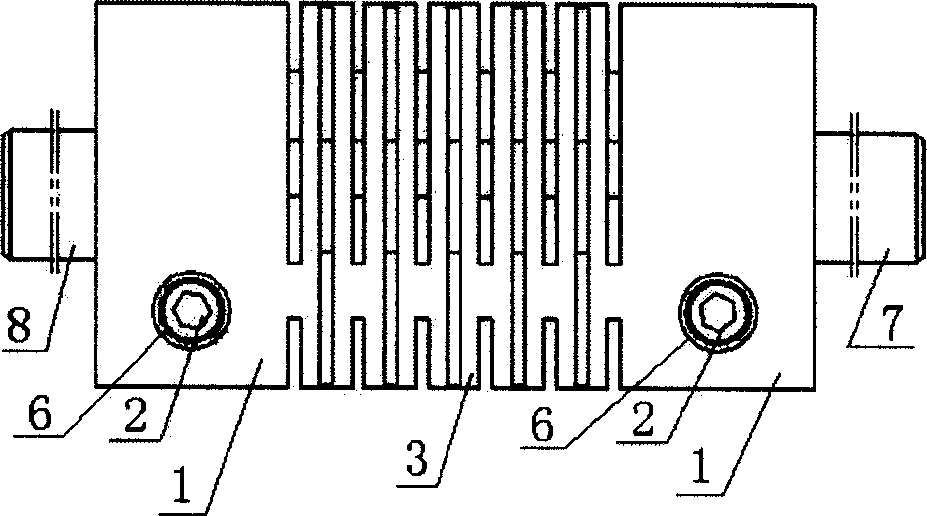

[0020] Such as figure 1 with 2 As shown, the main body of the integrated assembly-free compliant coupling of the present invention is cylindrical, the two ends of the main body are connecting ends 1 , and the middle part is a compliant mechanism 3 .

[0021] The connection end 1 has a connection hole 5 and a groove 4, the groove 4 divides the connection hole 5 into two parts, the groove 4 has a threaded hole 2 vertically, and the threaded hole 2 is equipped with a screw 6.

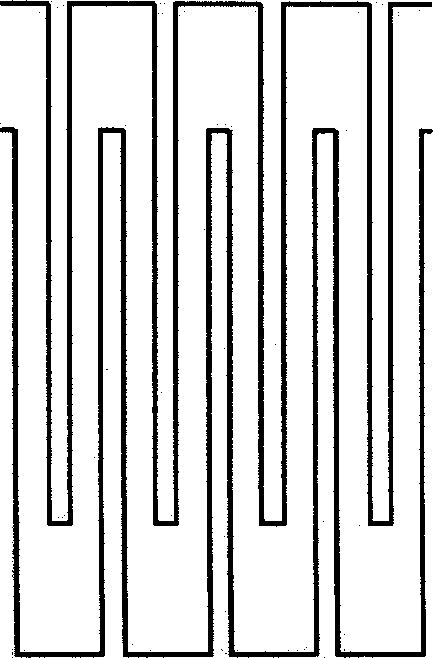

[0022] The compliance mechanism 3 is formed by connecting parallel circular plates.

[0023] The driving shaft 7 is assembled into the connection hole 5 of one of the connection ends 1, and the shaft is locked by the screw 6 in the threaded hole 2; the driven shaft 8 is assembled into the connection hole 5 of the other connection end 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com