Real time monitoring method for random loss rate of combine

A combine harvester, real-time monitoring technology, applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., can solve the separation performance, separation performance, cleaning performance is unstable, unaware of grain moisture and loss rate, no simultaneous testing The performance parameters of the combine harvester, such as random feeding amount, the ratio of grass to grain, the moisture content of grain, and the rate of grain loss, can improve production efficiency and operation quality, reduce labor intensity, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

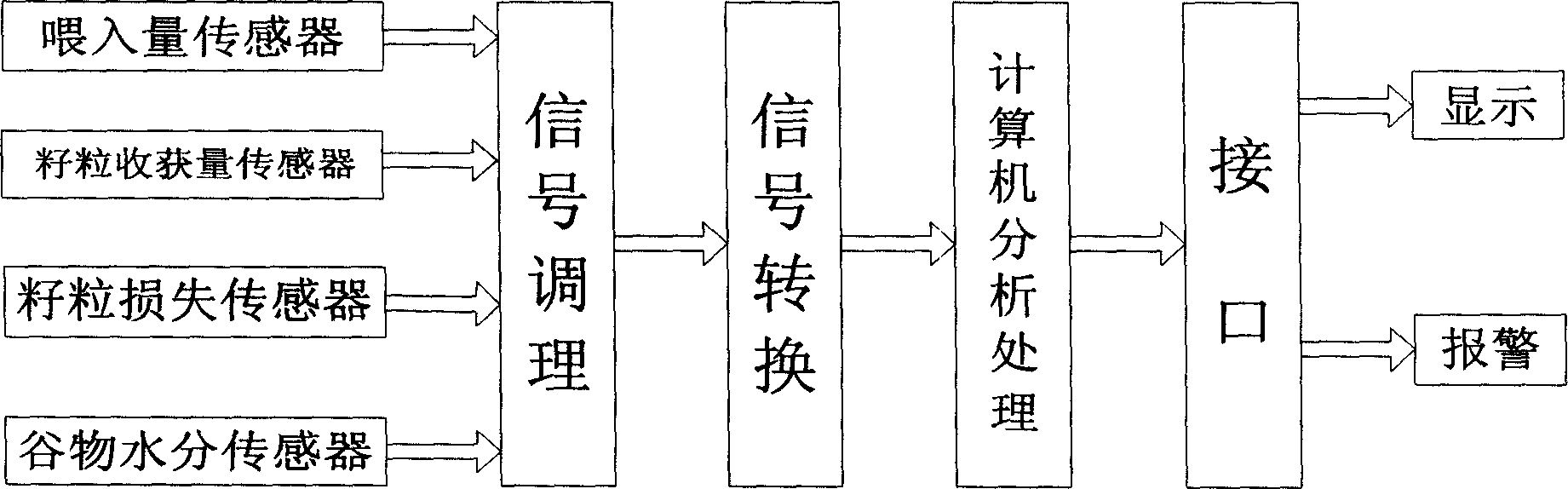

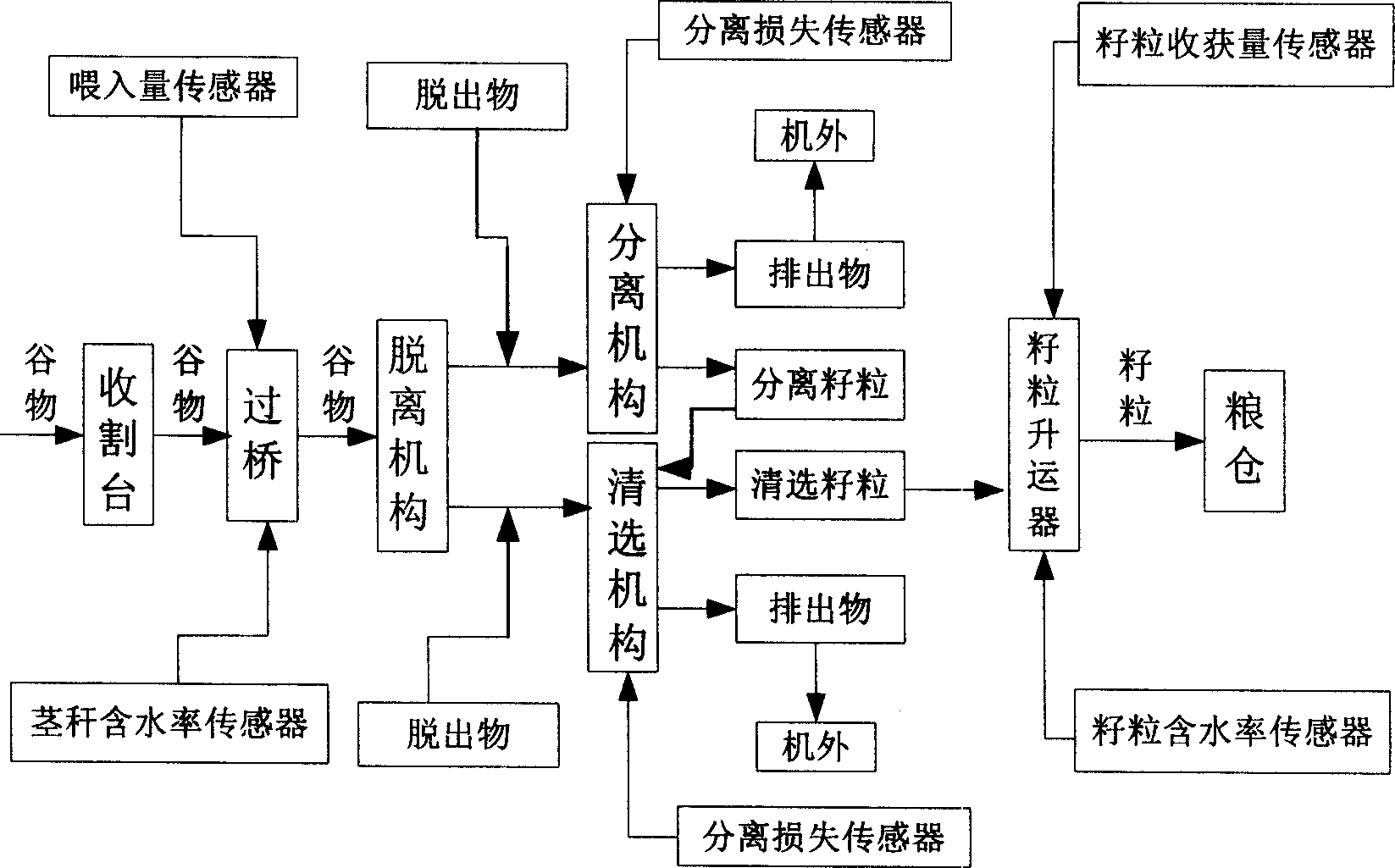

[0020]The working principle and implementation process of the monitoring system of the present invention are as follows: figure 1 and figure 2 As shown, the monitoring system implementing the real-time monitoring of the random loss rate of combine harvesters is composed of the following parts: signal acquisition part, signal conditioning part, signal conversion part, computer (such as single-chip computer, portable computer, desktop computer, etc.) analysis Processing part, interface circuit, display and alarm device and other parts. The signal acquisition part includes: feed amount sensor, grain harvest sensor, grain loss sensor (cleaning loss sensor, separation loss sensor), grain moisture sensor (stalk moisture content sensor, grain moisture content sensor), etc.

[0021] When the combine harvester is harvesting in the field and monitoring the random loss rate in real time, the header feeds the grain through the bridge equipped with the feed amount sensor, and the sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com