Contraction wind-power generator with mohaupt and speed increasement

A wind power generation device and energy collection technology, which are applied to wind turbine components, wind energy power generation, wind turbines, etc., can solve problems such as the inability to guarantee the optimal working conditions of wind turbine blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

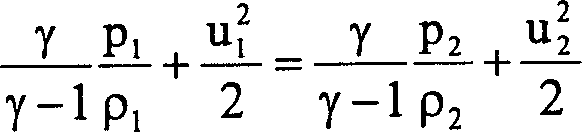

Method used

Image

Examples

Embodiment 1

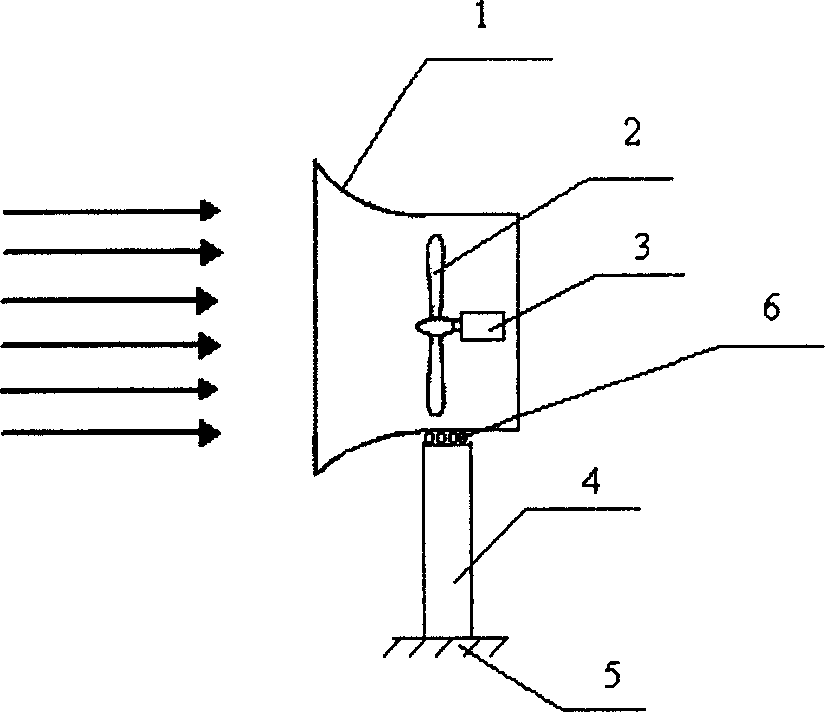

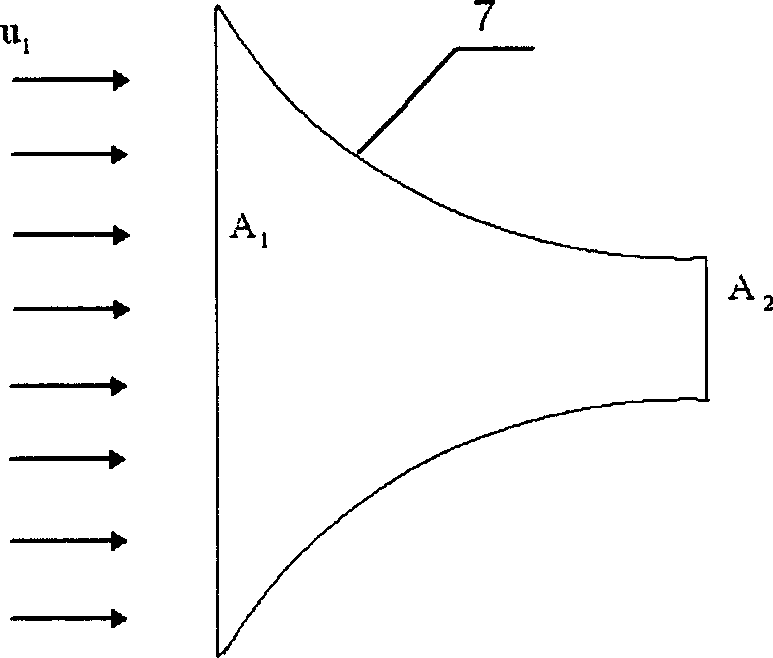

[0035] see figure 1 and figure 2 , the wind power generation device is on the foundation 5, a fixed tower 4, a rolling bearing mechanism 6 is fixed on the top of the tower 4, the rolling bearing structure adopts a one-way thrust ball bearing, and the shrinking nozzle 1 is supported on the rolling bearing structure 6 , the inlet section A of the shrinking nozzle 1 1 The diameter at the place is 100m, exit A 2 The diameter at the center is 25m, and the arc line 7 of the middle section of the contracting nozzle adopts a circular arc. The center of curvature of the arc is outside the flow channel, and the radius of curvature of the arc is 80m. The nozzle is made of composite materials, and the wall thickness is 0.007m.

Embodiment 2

[0037] see figure 1 and figure 2 , the wind power generation device is on the foundation 5, fixed tower 4, a rolling bearing structure 6 is fixed on the top of the tower 4, the rolling bearing structure adopts a one-way thrust ball bearing, and the shrinking nozzle 1 is supported on the rolling bearing structure 6 , the inlet section A of the shrinking nozzle 1 1 The diameter at the place is 1m, exit A 2 The diameter at the center is 0.1m, and the arc line 7 of the middle section of the contracting nozzle adopts a circular arc. The center of curvature of the arc is outside the flow channel, and the radius of curvature of the arc is 2m. m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com