Supporting and releasably holding device for a printing cylinder hub

A technology of cylinders and equipment, applied in general parts of printing machinery, printing, printing machines, etc., can solve problems such as inaccurate detection, gaps, printing errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

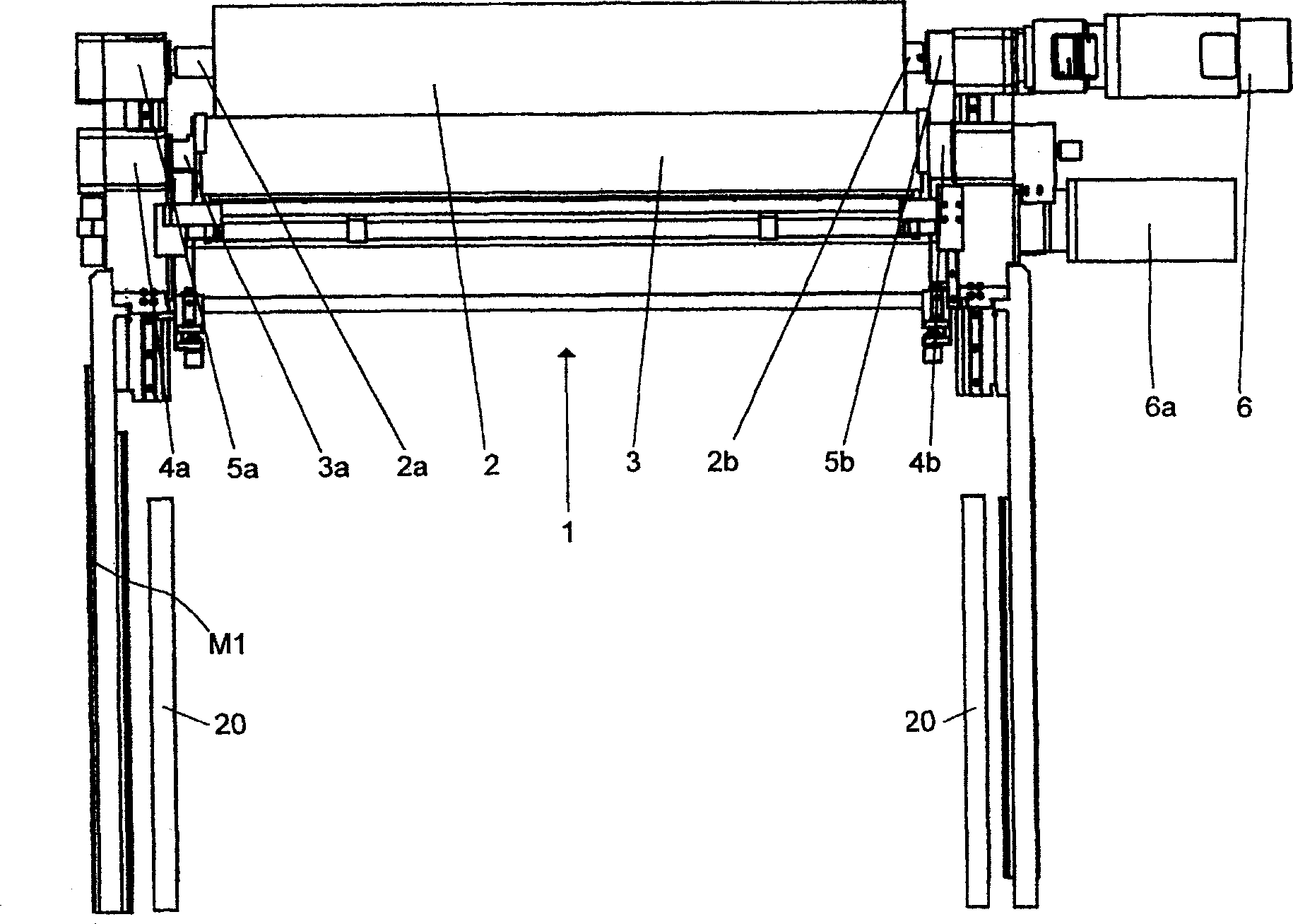

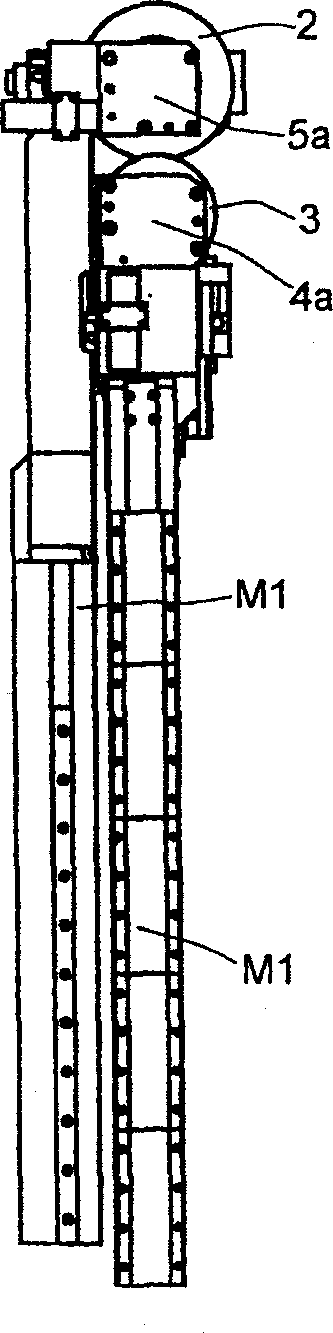

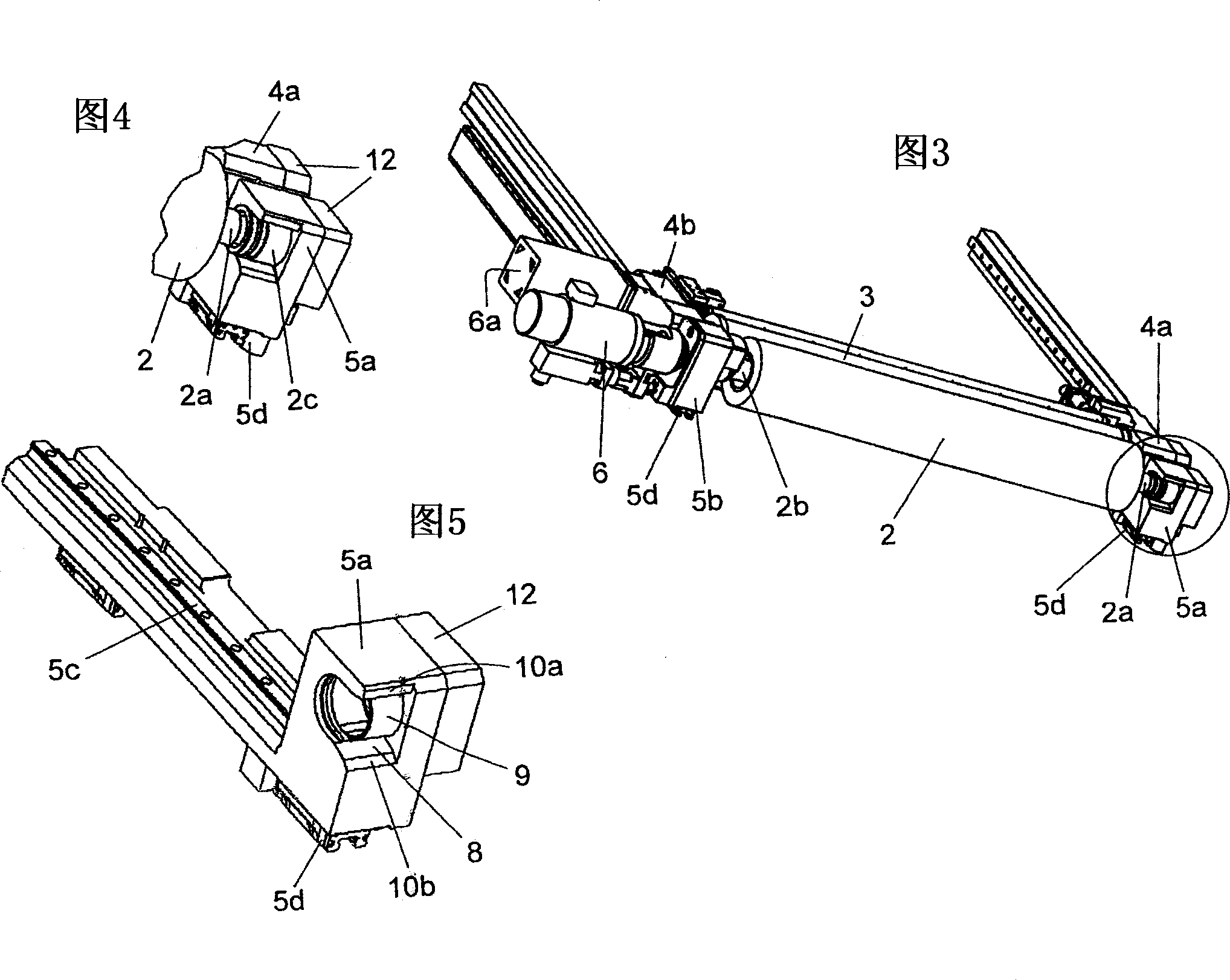

[0052] Referring first to the above-mentioned drawings, it can be noted that one of the components, a flexographic color assembly or unit 1, includes a stencil- or sleeve-loaded main cylinder 2 and a screen or interlocking cylinder 3 , at the ends of the two rollers are provided respective axially aligned hubs 2a, 2b and 3a, 3b (hub 3b not shown in the figures), as known to those skilled in the art.

[0053] The hubs 3a, 3b of the screen drum 3 are supported and rotated on a first pair of sliding supports 4a and 4b, which in turn are slidably mounted on corresponding parallel guides 5c (Fig. 5), guiding The member 5c is arranged on a second pair of sliding supports 5a and 5b, each support 5a or 5b rotatably supports a corresponding hub 2a, 2b of the stencil carrying cylinder 2, and is provided with a guide element 5d, so that The guide element 5d described is designed to slidably engage a corresponding guide (not shown in the drawings) parallel to the guide 5c, and is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com