Analyzing system and analysing method based on integrated micro-flow control chip

A microfluidic chip and analysis system technology, applied in the field of micro-total analysis, can solve problems to be developed, and achieve the effects of simple operation, high sensitivity and fast analysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

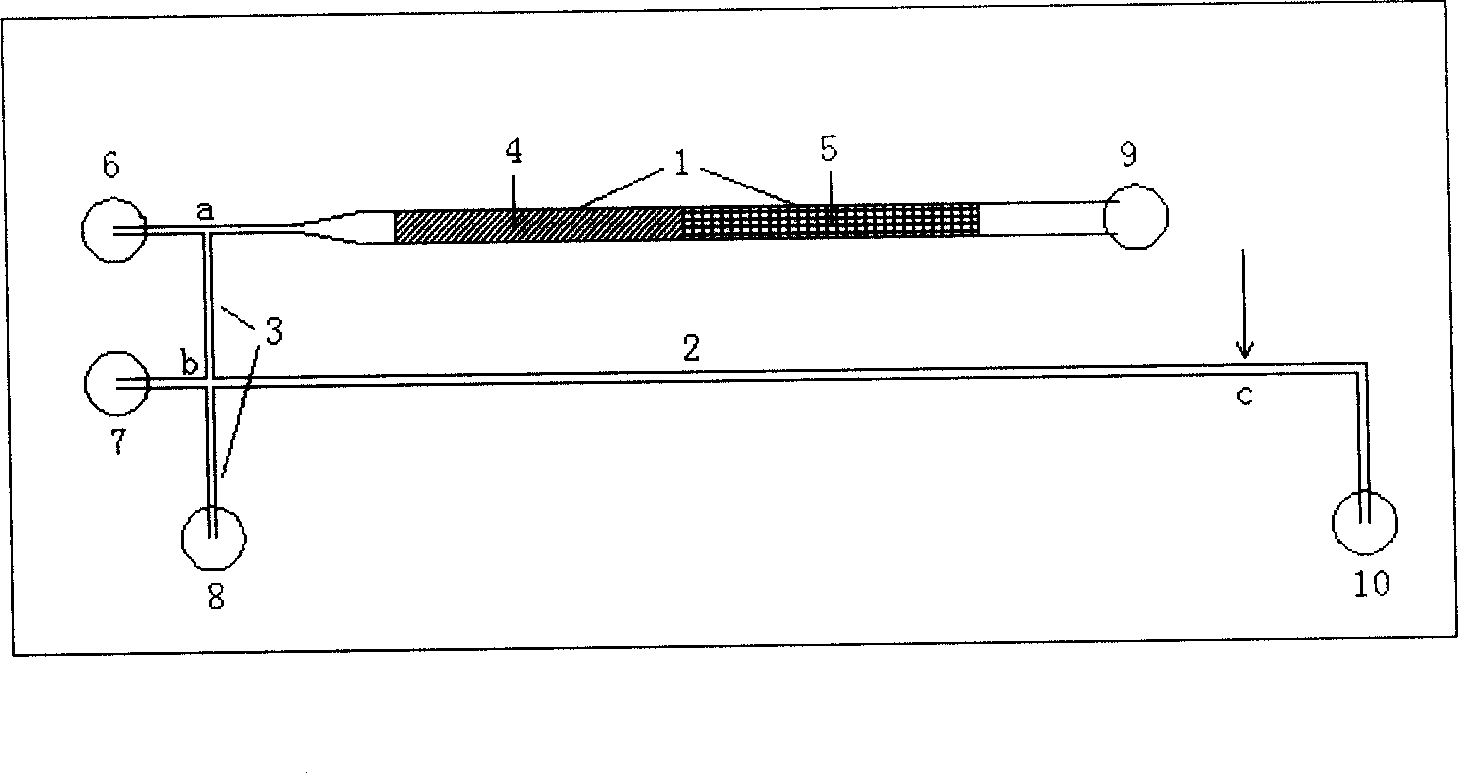

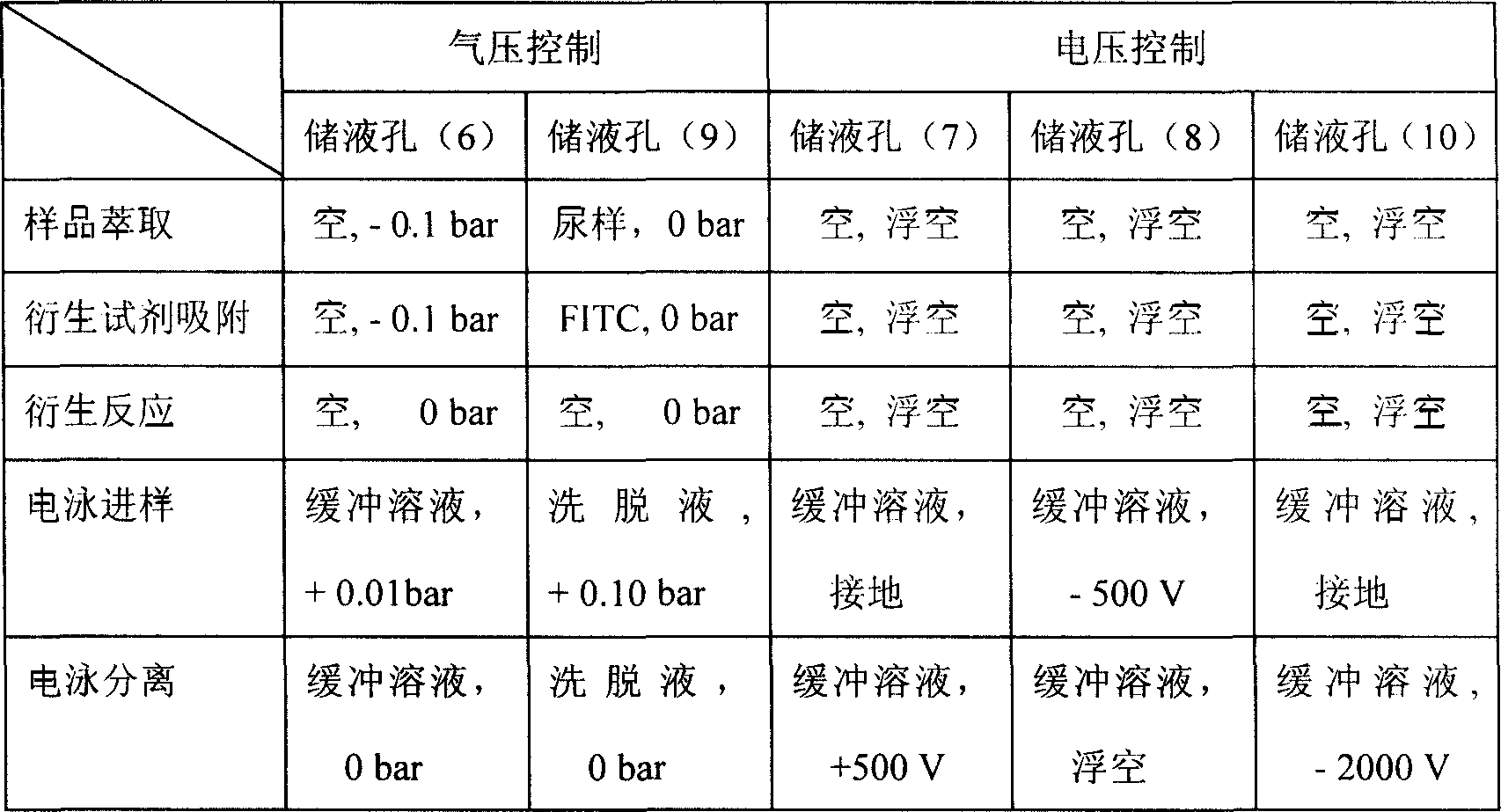

[0020] Example: Detection of the stimulant amphetamine in urine by the system. like figure 1 As shown, the microfluidic chip is made of glass, with a length of 5.0 cm, a width of 2.5 cm, a bottom plate with a thickness of 1.0 mm, and a cover plate with a thickness of 0.5 mm. The length of the pretreatment channel 1 is 3 cm, the depth is 100 μm, and the width at half maximum is 180 μm. Separation channel 2 is 4.2 cm long, 100 μm deep, and 125 μm wide at half maximum. The sampling channel is 5 mm long on both sides of the intersection b, and the inner diameter of all liquid storage holes is 2 mm. The distances from the T-shaped intersection a to the liquid storage hole 6 and from the cross intersection b to the liquid storage hole 7 are 3 mm respectively. The pretreatment channel 1 is filled with a dual-phase solid phase carrier: the porous polymer monolithic column 4 (vinyl dimethacrylate and methyl Copolymer of butyl acrylate), and then fill the gas chromatography filler 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com