Anti-scour and cavitation-resistant high pressure difference regulating valve

A high-pressure differential and regulating valve technology, applied in the field of high-pressure differential regulating valves, can solve problems affecting the service life of high-pressure differential regulating valves, improve the performance of anti-scouring and cavitation resistance, reduce impact and cavitation, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

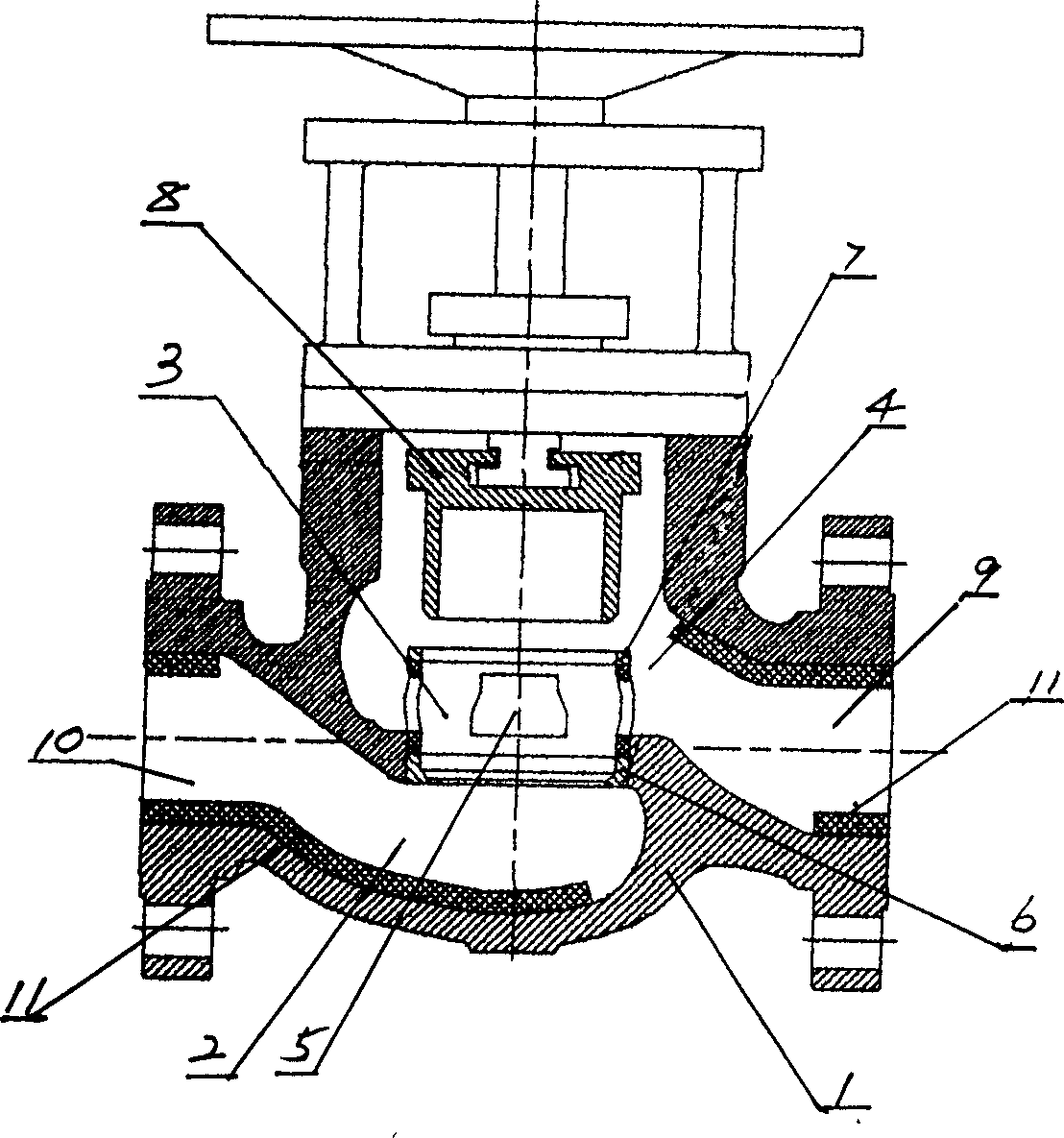

[0019] When the present invention is used in a system with a steam pressure difference of 3.7Mpa between the valve inlet and the outlet;

[0020] The specification of the valve body 1 of the present invention adopts a PN of 64Mpa and a DN of 50mm. Among them, the diameter of the sleeve 3 is 70mm and the height is 40mm; four orifices 5 are evenly arranged on the cylinder wall, and the distance between the orifice 5 and the sealing surface A6 is 3mm; the inlet 10 and the outlet 9 of the valve body 1 are lined with The structural ceramic layer 11 is covered, and the bottom of the inlet channel 2 and the position of the valve body cavity 4 close to the outlet 9 are lined with the structural ceramic layer 11 .

[0021] When the valve plug 8 is inserted into a part of the sleeve 3, the valve plug 8 covers a part of the orifice 5 on the cylinder wall of the sleeve 3, and the high-pressure steam enters the inlet passage 2 through the inlet 10, and passes through the uncovered part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com