Fumed metal oxide particles and process for producing the same

A technology of oxide particles and oxides, applied in the preparation of alumina/hydroxide, chemical instruments and methods, silicon oxide, etc., can solve problems such as expensive processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

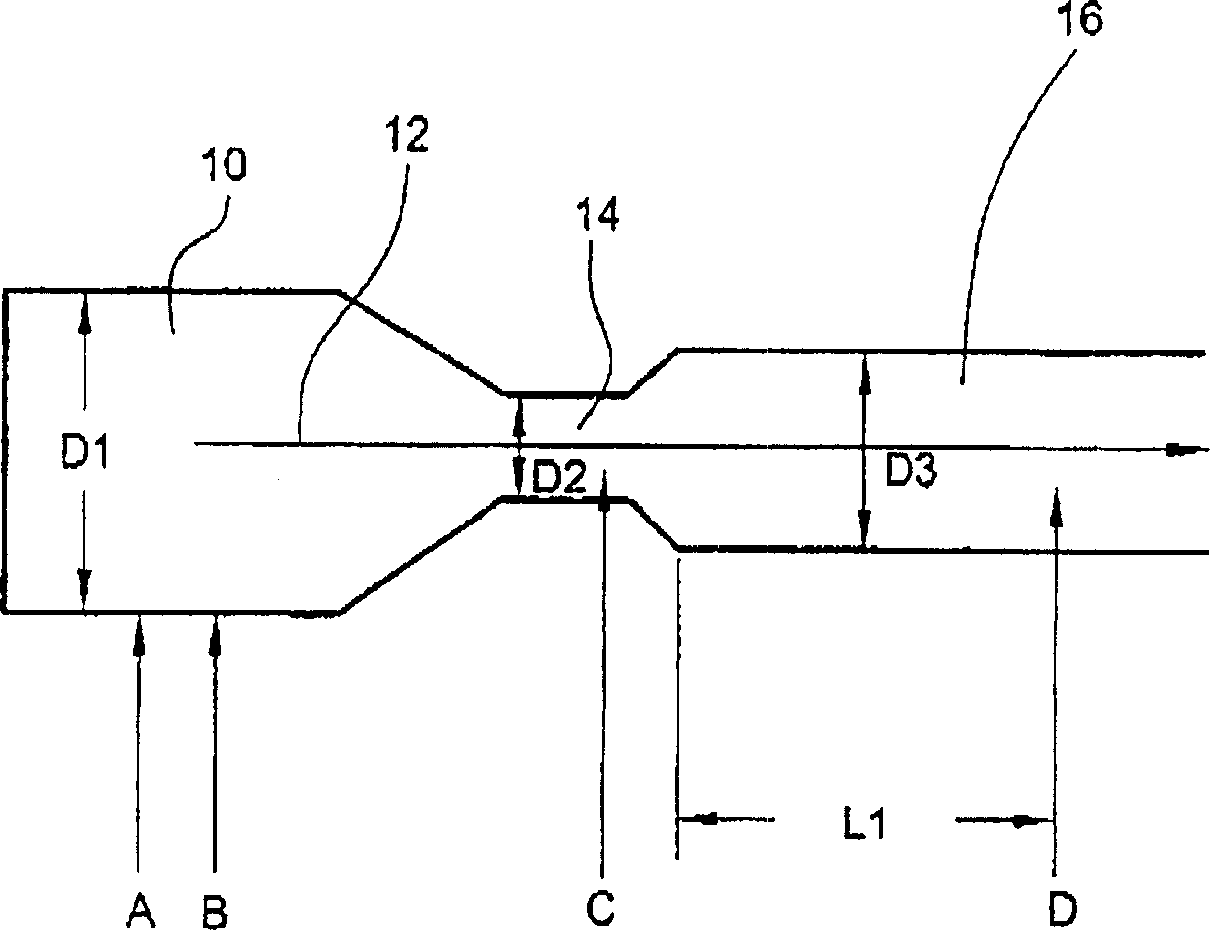

[0046] These examples illustrate the method of making fumed metal oxide particles according to the invention. In particular, these examples illustrate four methods for producing fumed silica particles with different surface areas. Use as above and asfigure 1 The described pilot scale reactor was used for the following process. refer to figure 1 , the approximate dimensions of the pilot scale reactor are as follows: D1 = 18.4 cm, D2 = 9.7 cm, D3 = 69 cm, and L1 = 213 cm. The liquid feedstock was commercially available octamethylcyclotetrasiloxane (OMTS) and the combustion gas flow was established by burning a mixture of air and natural gas. The amounts of air, natural gas, and OMTS used in each method are shown in Table 1. In the constriction 14 of the reactor (i.e., figure 1 The portion with diameter D2 in ) injects liquid feedstock (i.e. OMTS) into the combustion gas stream and uses water (which is in figure 1 The D position in is introduced into the reactor) to quench t...

Embodiment 5

[0052] This example demonstrates the unique particle size characteristics of the fumed silica particles of the present invention. The fumed silica granules of Examples 1-4 were analyzed according to the method described here to determine the primary Particle size d and aggregate size D of 2000 aggregates circ . Then calculate the average primary particle size d ave , average aggregate size D circ ave , and the geometric standard deviation σ of the aggregate size g (D circ ). Specifically, using the BET surface area (SA) measurement and the equation: d ave (nm)=1941 / SA(m 2 / g) Determination of the mean value d of the primary particle size of the fumed silica particles ave . Measure the area A of each aggregate using TEM image analysis and use the equation D circ = 4 A / π Calculate aggregate size D circ to determine the aggregate size D circ . Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com