Water electrolytic treatment system of ballast for cruising

A technology for ship ballast water and electrolytic treatment, which is applied in the field of electrochemical oxidation to achieve the effect of increasing dissolved oxygen, reducing the content of COD and TOC, and has strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

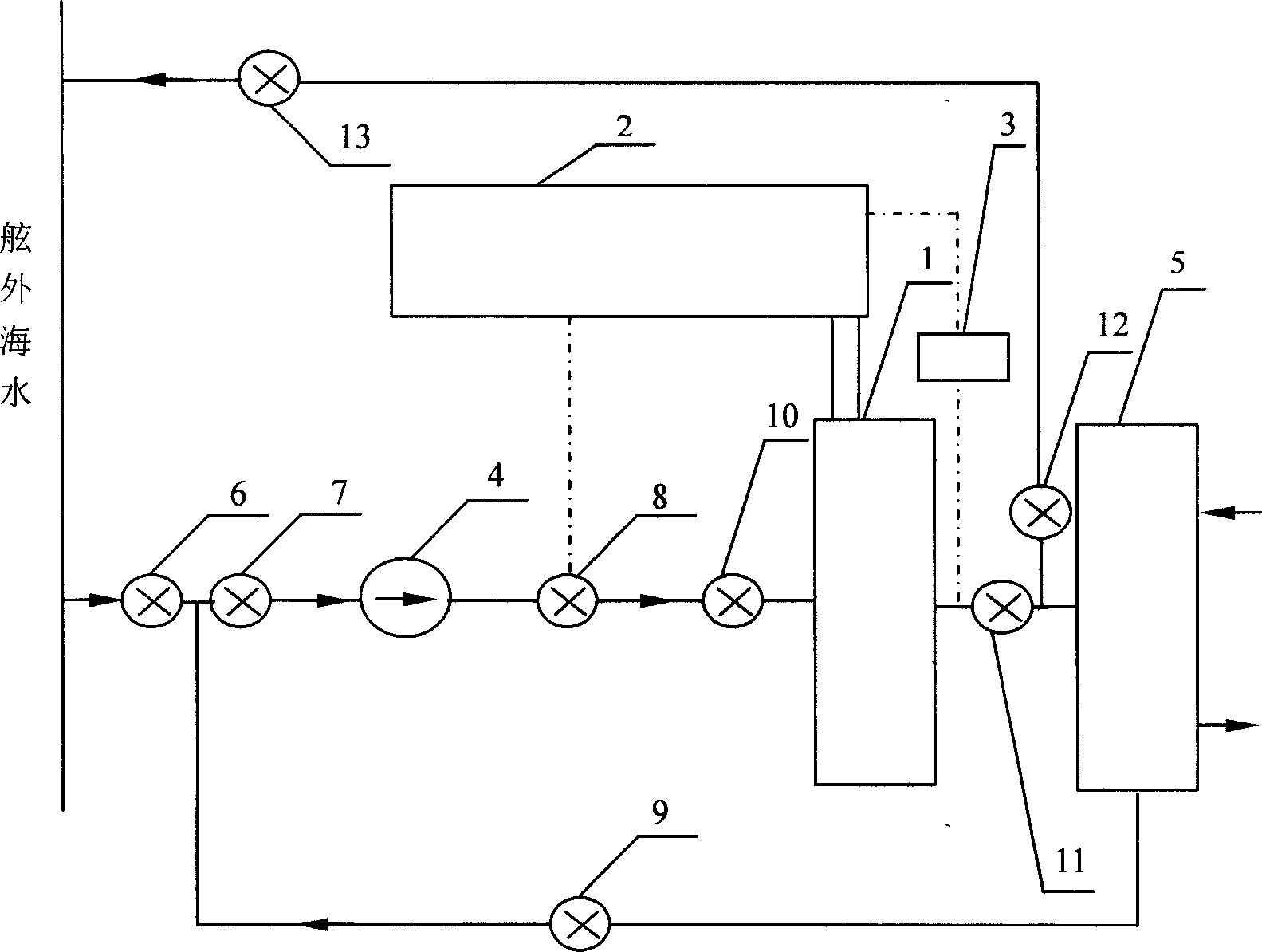

[0011] The applicable flow rate of electrolytic processor 1 is 50m 3 / h, the operating voltage of the electrolytic processor 1 is 8V, the distance between the cathode and the anode of the electrolytic processor 1 is 4.5mm, the material used for the negative electrode of the electrolytic processor 1 is stainless steel 1Cr18Ni9Ti, and the coating of the DSA anode of the electrolytic processor 1 The layer is ruthenium dioxide, and the ballast pump 4 is a centrifugal pump.

[0012] During the pumping process of the ship’s ballast water, it is processed according to the following steps: the outboard seawater enters the electrolysis processor 1 through the valve control valve 6 and the control valve 7 from the ballast pump 4 through the outlet valve 8 and the processor inlet valve 10 for direct electrolysis treatment, and then Enter the corresponding ballast compartment through the ballast valve box 5. At this moment, the control valve 9 and the control valve 12 are closed; when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com