Anticurling agent, ink jet ink, method for ink jet recording and method for reducing curling

A technology of reducing agent and curling, applied in the directions of ink, application, and roll-resistant paper, etc., can solve the problem of inconvenience in saving recorded products, and achieve the effect of easy handling and curly suppression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

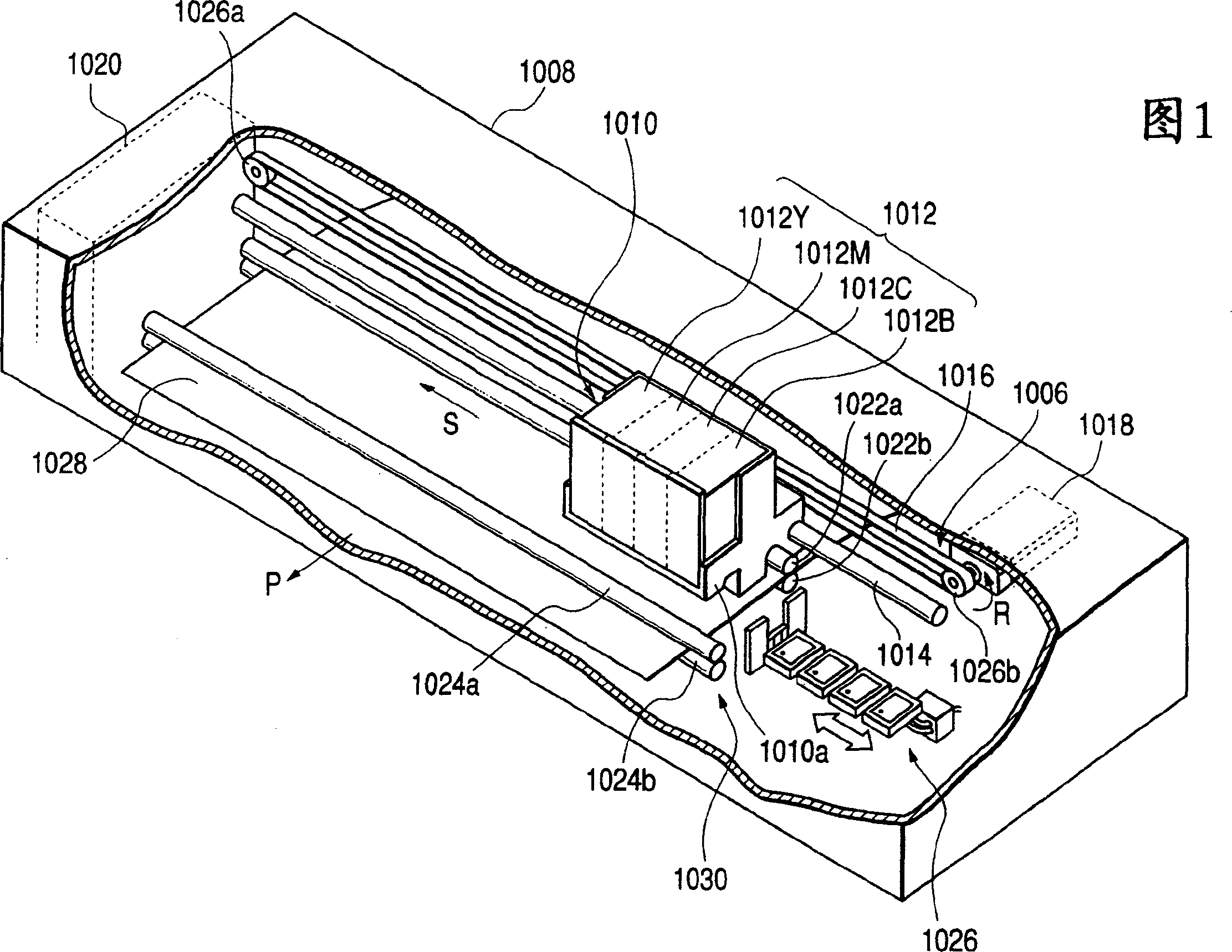

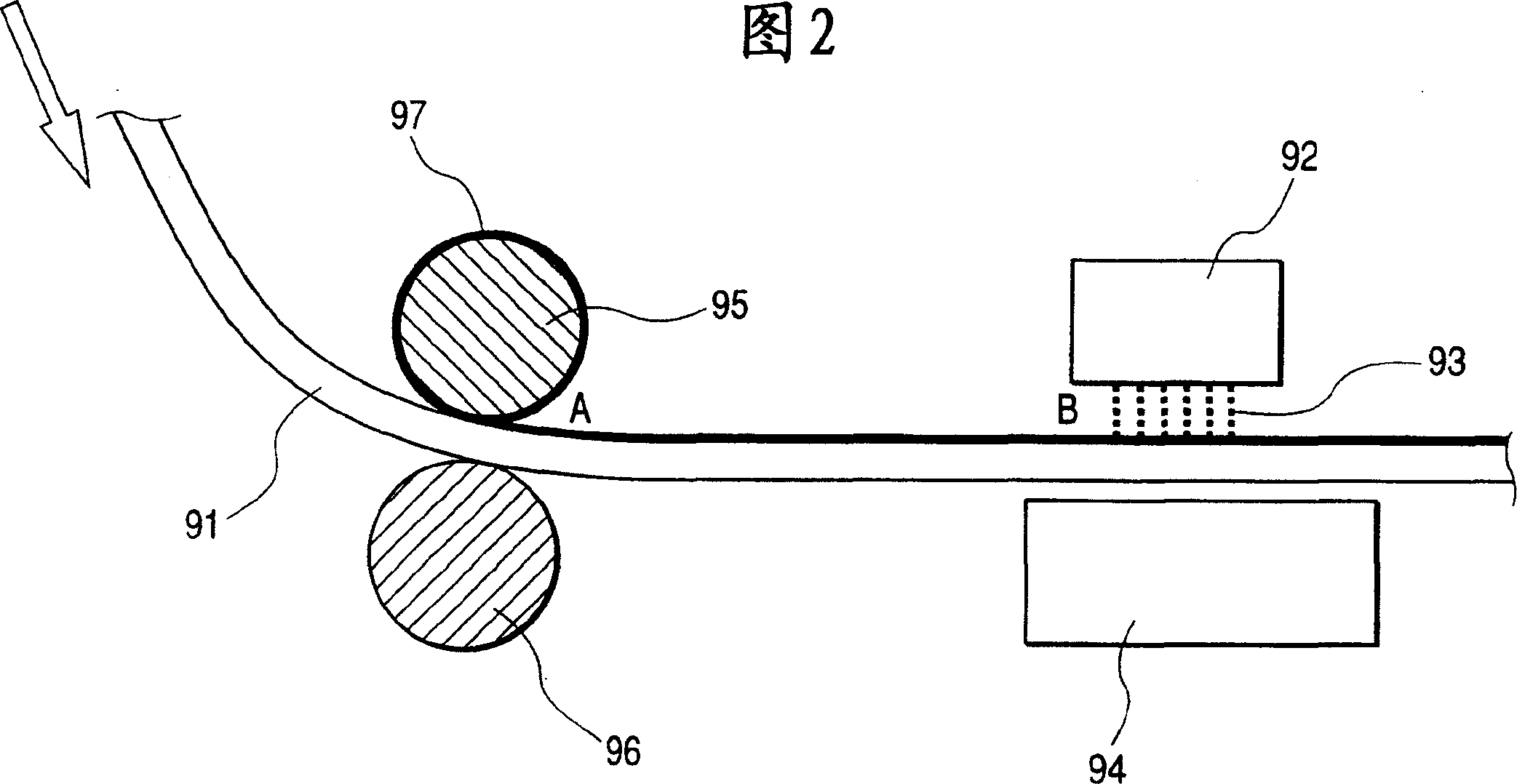

Image

Examples

Embodiment 2~11、 comparative example 1 and 2

[0090] In the same manner as in Example 1, using the compounds shown in Table 2, the inks of Examples 2 to 11 and Comparative Examples 1 and 2 were obtained.

Embodiment 12

[0092] Preparation of yellow ink

[0093] A styrene-acrylic acid copolymer (Joncryl 678, manufactured by Jiyon Sompolima Co., Ltd.) was mixed with a prescribed amount of sodium hydroxide and water necessary to neutralize them. Furthermore, these were stirred and mixed with heat-retaining at about 60 degreeC, and the 10% styrene-acrylic acid copolymer aqueous solution was obtained.

[0094] Then, the following ingredients were mixed, stirred for 30 minutes, and then dispersed under the following conditions.

[0095] 30 parts of 10% aqueous solution of styrene-acrylic acid copolymer

[0096] ·Pigment Yellow-74 10 parts

[0097] ·60 parts of ion-exchanged water

[0098] · Dispersing machine: sand mill (manufactured by Aimex Co., Ltd.)

[0099] ·Grinding medium: zirconium flakes with a diameter of 1mm

[0100] ·Filling rate of crushing medium: 50% (volume ratio)

[0101] ·Crushing time: 3 hours

[0102] Further, centrifugation treatment (12000 rpm, 20 minutes) was performed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com