Energy-saving vibration-preventing hammer

An anti-vibration hammer and hammer body technology, applied in mechanical vibration damping devices and other directions, can solve the problems of unsatisfactory vibration damping effect, unstable grip force, short service life, etc., and achieve stable grip force, long service life and strong corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

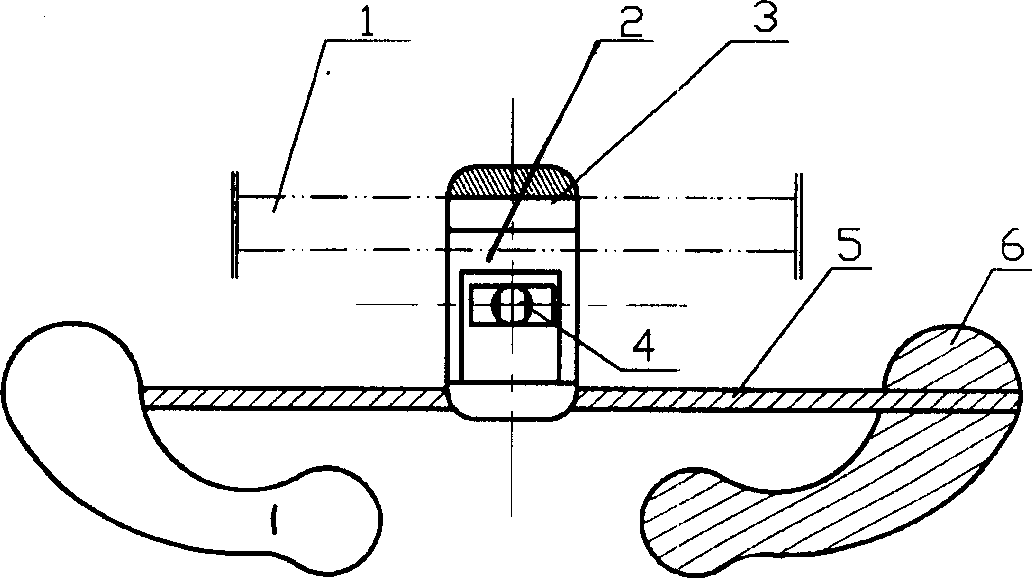

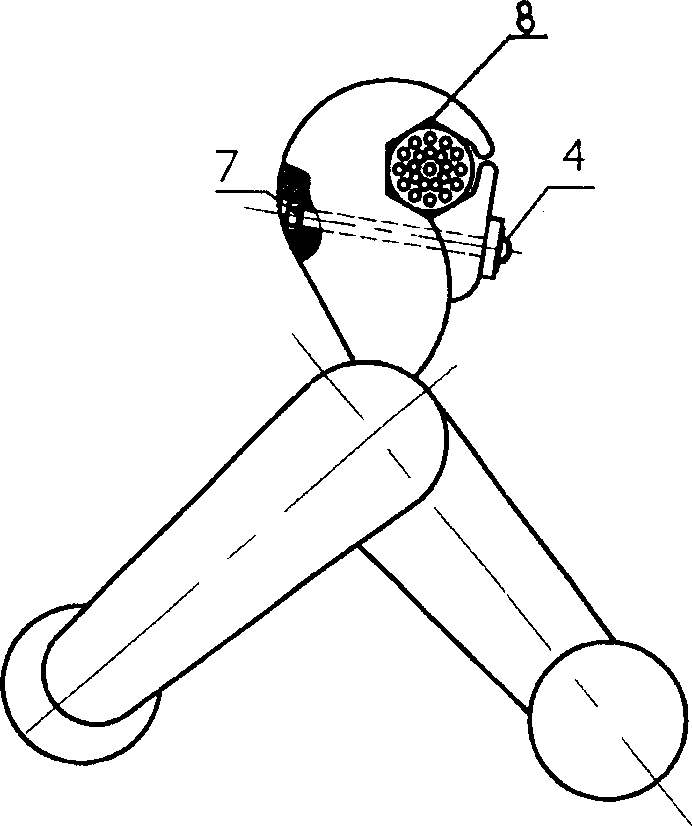

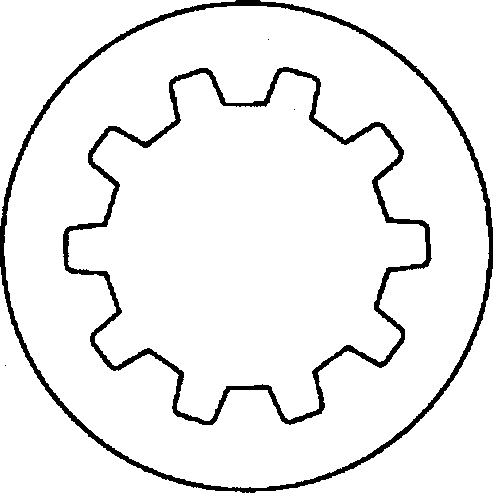

[0013] Embodiment: It is composed of wire clamp 2, steel strand 5, and hammer body 6. The wire clamp 2 adopts a two-half-circle Hafur structure, and the outer contour of the wire clamp 2 is smooth and excessive. The hexagonal hole 8 is provided with a left-handed anti-skid pattern 3, the lower end of the wire clamp 2 is die-cast in the middle of the steel strand 5, the hemispherical head bolt 4 passes through the wire clamp 2, and is fastened with a helical tooth-shaped anti-loosening anti-retraction ring 7 and a nut. The two ends of the steel strand 5 are die-casted together with the hammer body 6. The hammer body 6 is made of non-magnetic zinc alloy material and is in the shape of an elbow fist. The external contour of the hammer body 6 is smooth and excessive. The inner hole wall of the tooth-shaped anti-loosening and anti-retreating ring 8 is provided with helix angle anti-retraction teeth 9 corresponding to the hemispherical head bolt 4 thread pitches. Loosening and anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com