Waterproof sheet in-situ application machine

一种贴附机械、防水膜的技术,应用在屋顶工程用的工具、建筑构件、建筑保温材料等方向,能够解决花费时间等问题,达到确保粘接性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

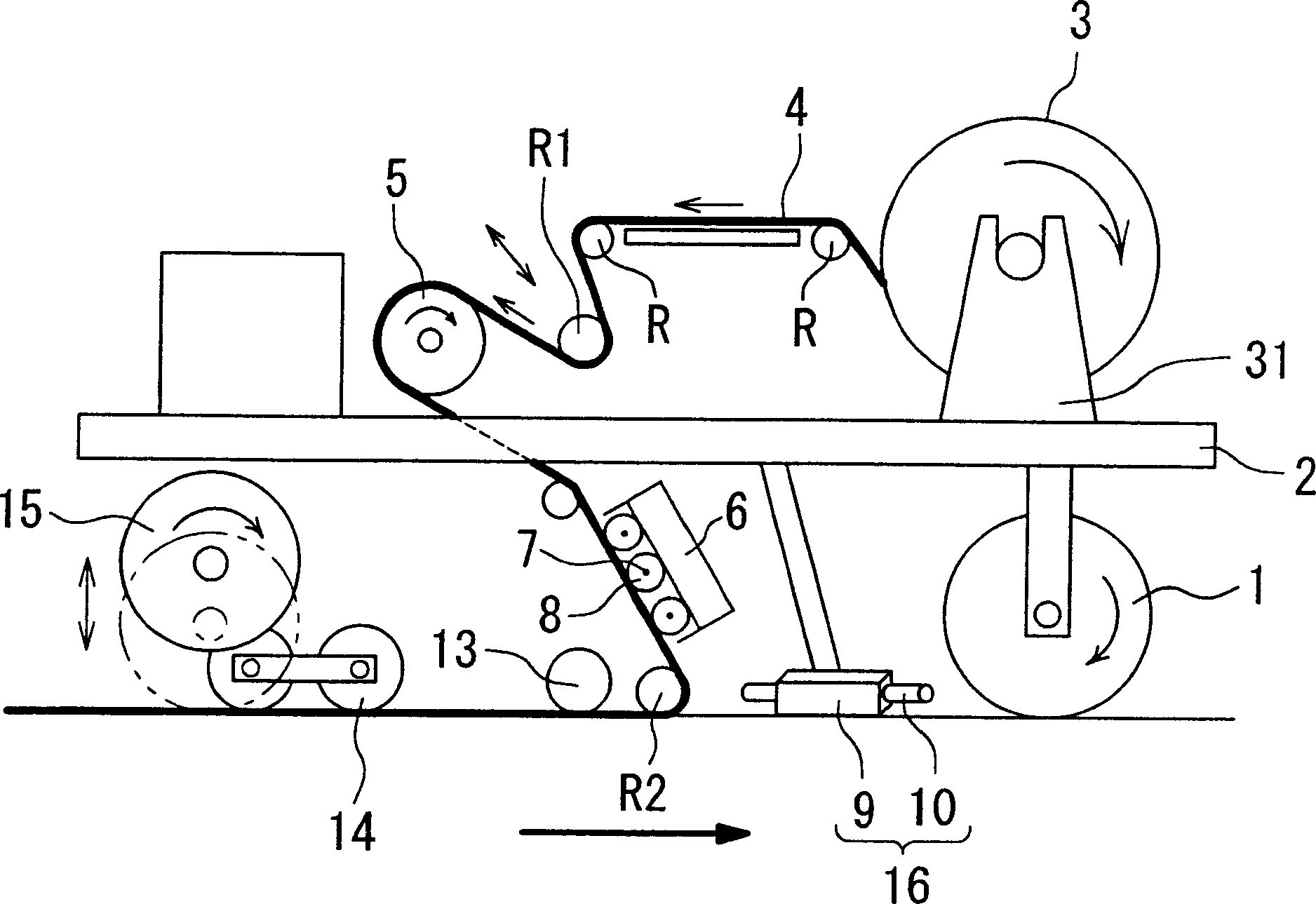

[0039] Construction machine of the present invention such as figure 1 The shown consists of the following structures.

[0040] 1. Self-propelled trolley

[0041] It is a self-propelled trolley (2) provided with wheels (1) driven by hydraulic drive, electric drive or engine, and can perform operations such as changing forward and backward directions.

[0042] 2. Waterproof membrane stand

[0043] A stand (31) capable of placing a waterproof membrane roll (3) with a length of 300m to 400m for a roll of waterproof membrane.

[0044] 3. Anti-wrinkle drum

[0045] In order to attach the waterproof membrane to the construction surface smoothly without wrinkles, a roller (5) that rotates in the opposite direction to the movement direction of the waterproof membrane (4) is provided. It rotates, thereby preventing slack and bending of the film, preventing occurrence of wrinkles at the time of attachment.

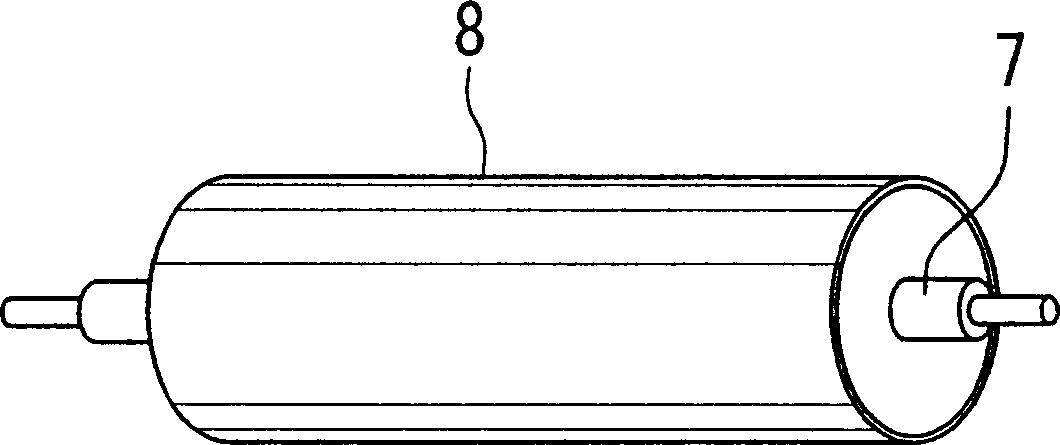

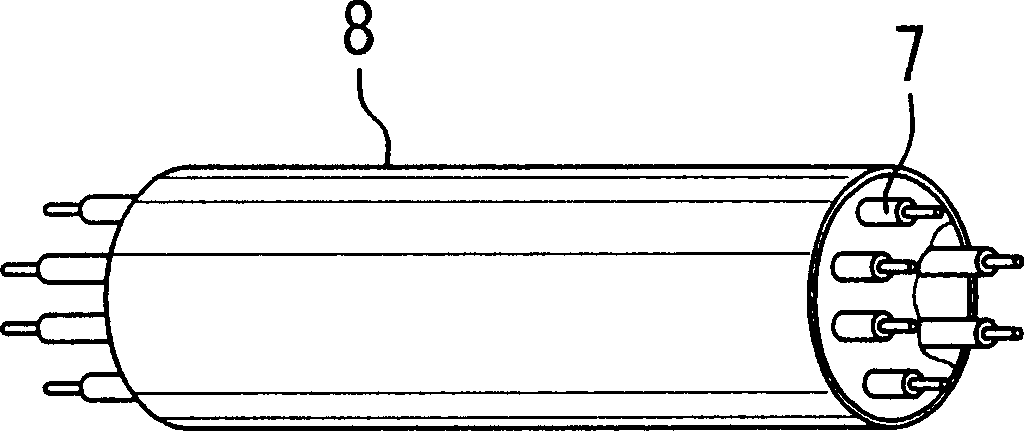

[0046] 4. Film heating device

[0047] As the film heating device (6), it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com