Piston for a hydraulic brake system and master cylinder equipped therewith

A hydraulic brake and piston technology, applied in the direction of hydraulic brake transmission device, brake transmission device, fluid pressure actuation device, etc., can solve problems such as wear and tear, achieve uniform pressure distribution, reduce the risk of jamming or blocking, Reliable and fast closing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

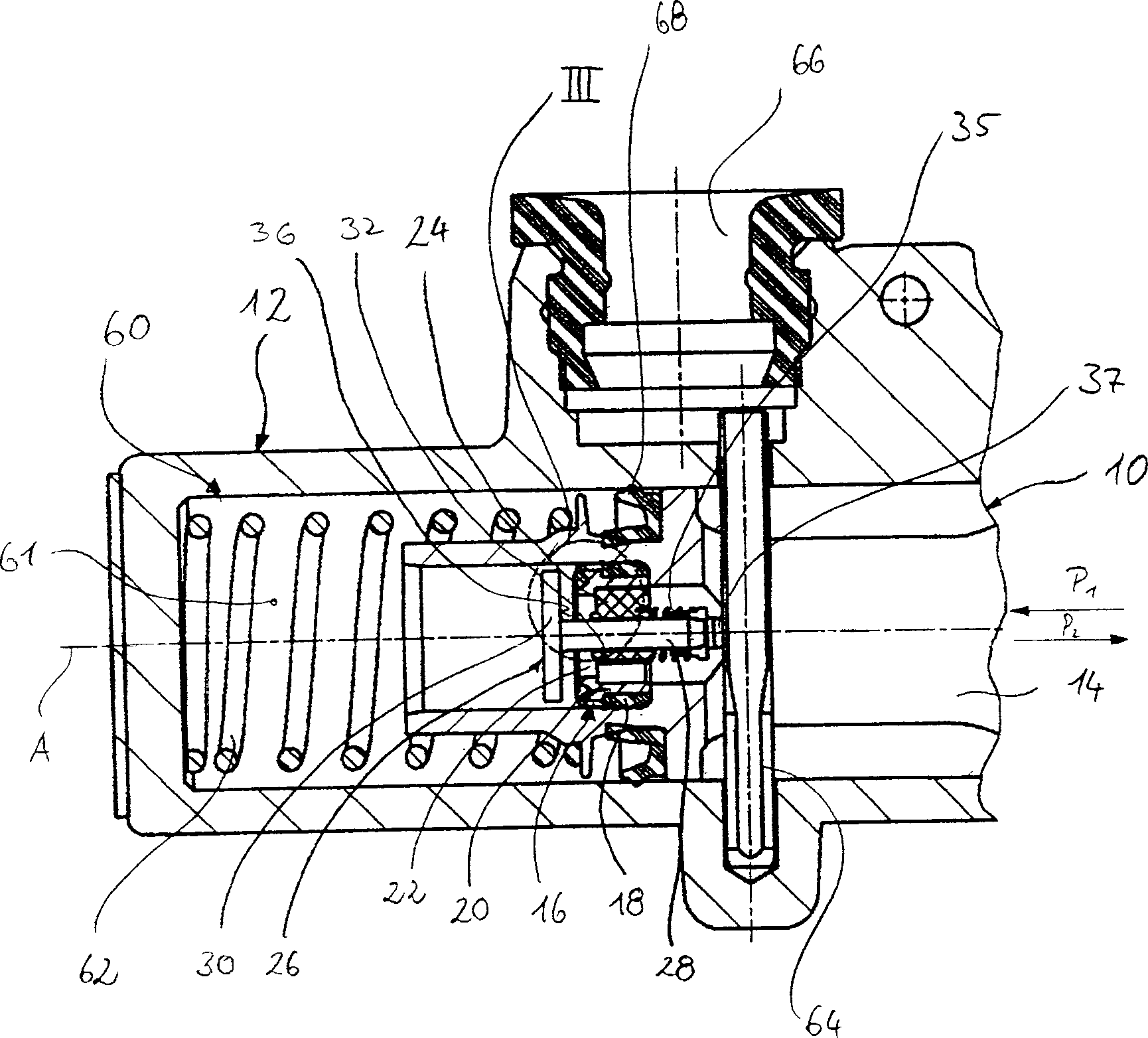

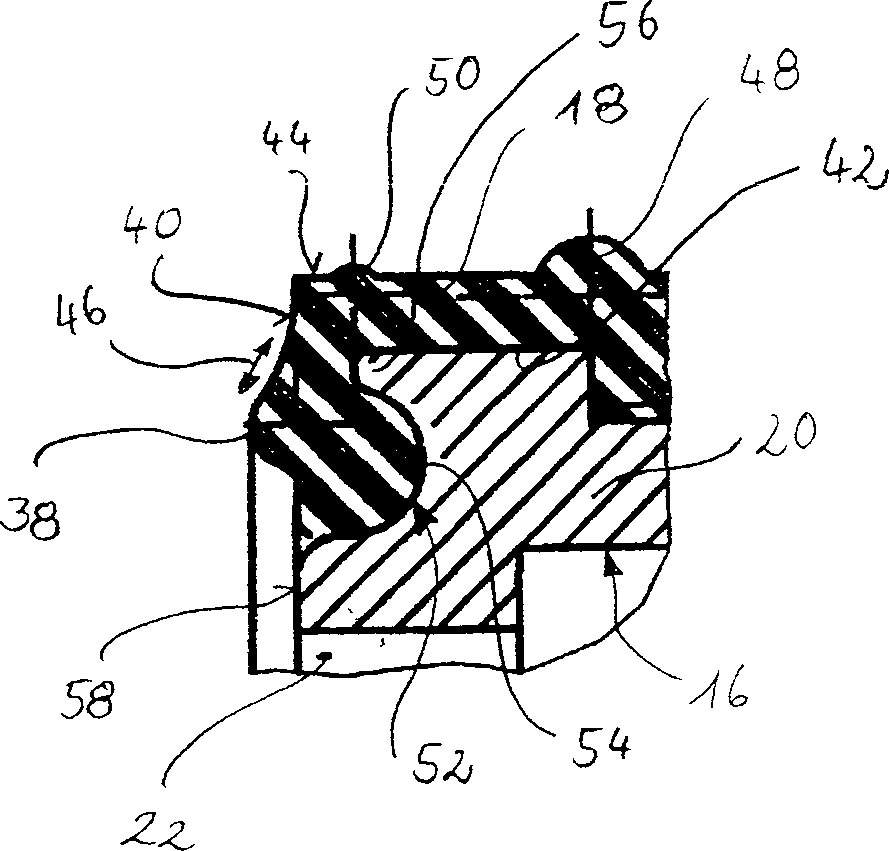

[0022] exist figure 1 In , a piston according to the invention is shown in a partial sectional view including the axis and is indicated generally at 10 . The piston 10 is movably guided in the direction of the axis A in the cylinder housing 12 of the master cylinder. The piston 10 is provided with a stepped piston channel 14, which axially passes through the piston. The sealing member 16 comprising the sealing element 18 and the support element 20 is adhesively mounted in the piston channel 14 by press-fitting. Additional detail on sealing member 16 will be provided below.

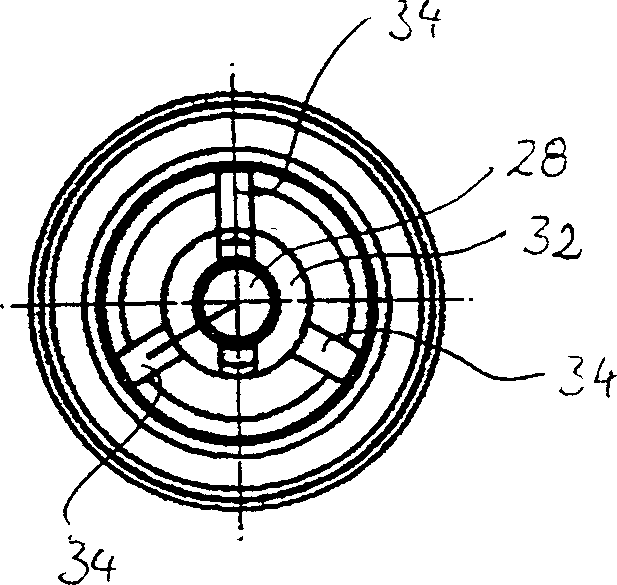

[0023] The sealing member 16 is likewise provided with a central stepped channel 22 in which the guide element 24 is received and press-fitted so as to be locked against movement. In the guide element 24 a valve element 26 is guided in an axially movable manner. The valve element 26 includes a valve tappet 28 and a valve disk 30 . In order to guide the valve element 26 in the guide element 24, the val...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap