Compound expansion joint

An expansion joint, composite technology, used in bridge parts, bridges, buildings, etc., can solve the problems of fragile durability, low operation efficiency, and complex substructure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

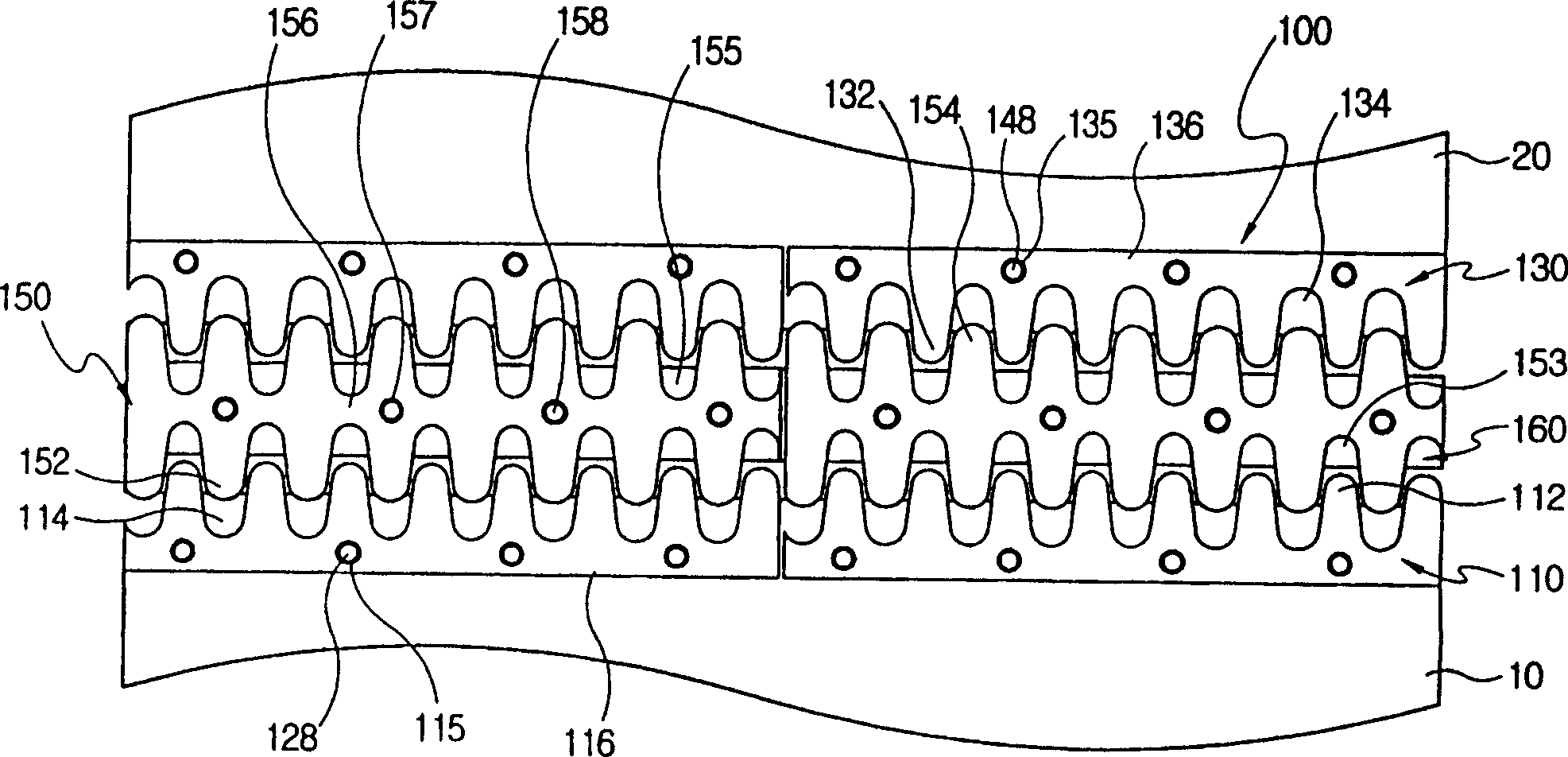

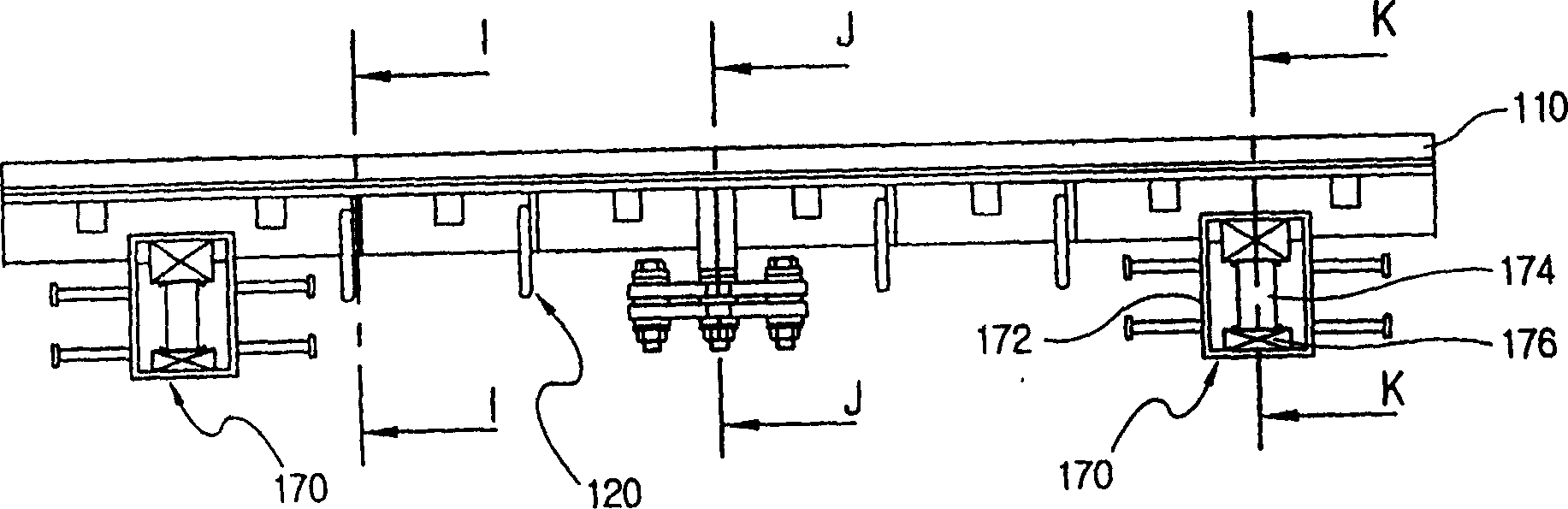

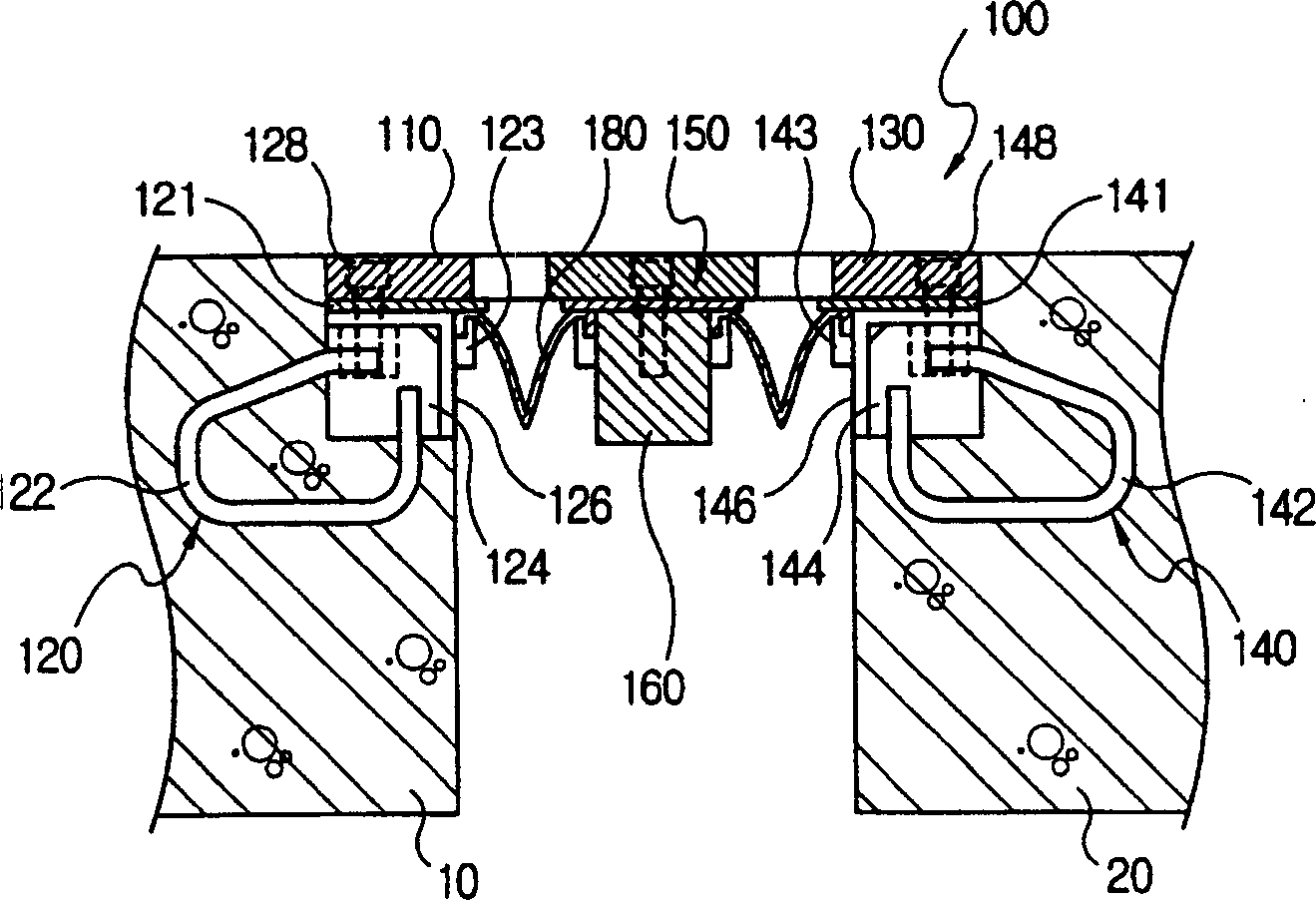

[0023] The composite expansion joint according to the present invention is located between the first superstructure and the second superstructure of the bridge oppositely arranged at intervals, allowing the expansion and contraction of the two superstructures and supporting the wheels passing between the two superstructures. An expansion joint for a bridge passing smoothly between two superstructures, including first pin members arranged on the edge of the first superstructure and alternately forming pins (fingers) and pin slots toward the second superstructure, the first The pin member is fixedly supported on the first pin support member of the first superstructure, and the second pin member is provided opposite to the first pin member on the edge of the second superstructure and alternately forms pins and pin grooves toward the first superstructure. , to fix and support the second pin member on the second pin support member of the second upper structure, between the first pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com