Fuel vapor vent valve float assembly and method of making same

A technology for exhaust valves and floats, which is applied to the direction of the float, lift valve, and valve device of the control valve, which can solve the problem of central part exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

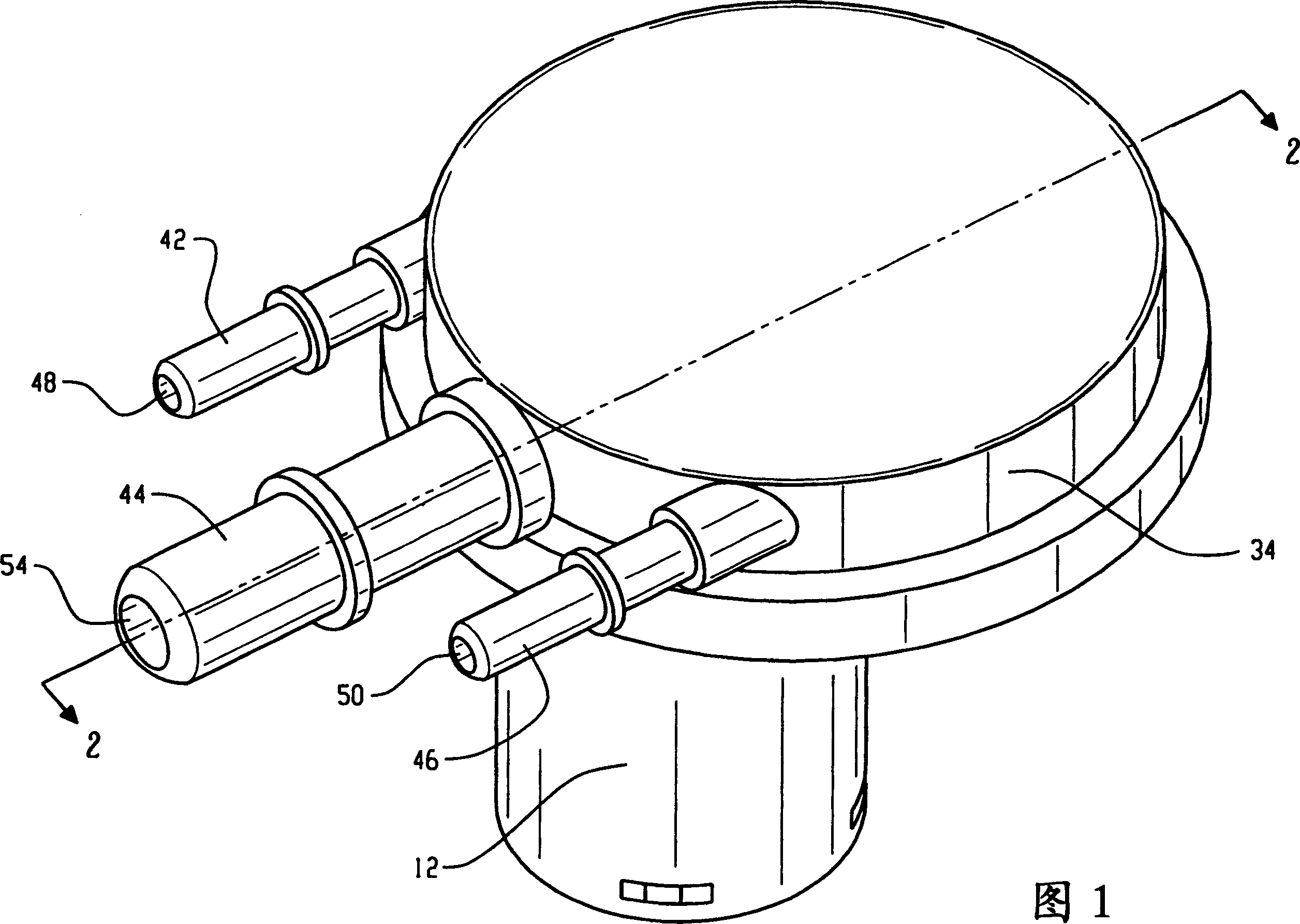

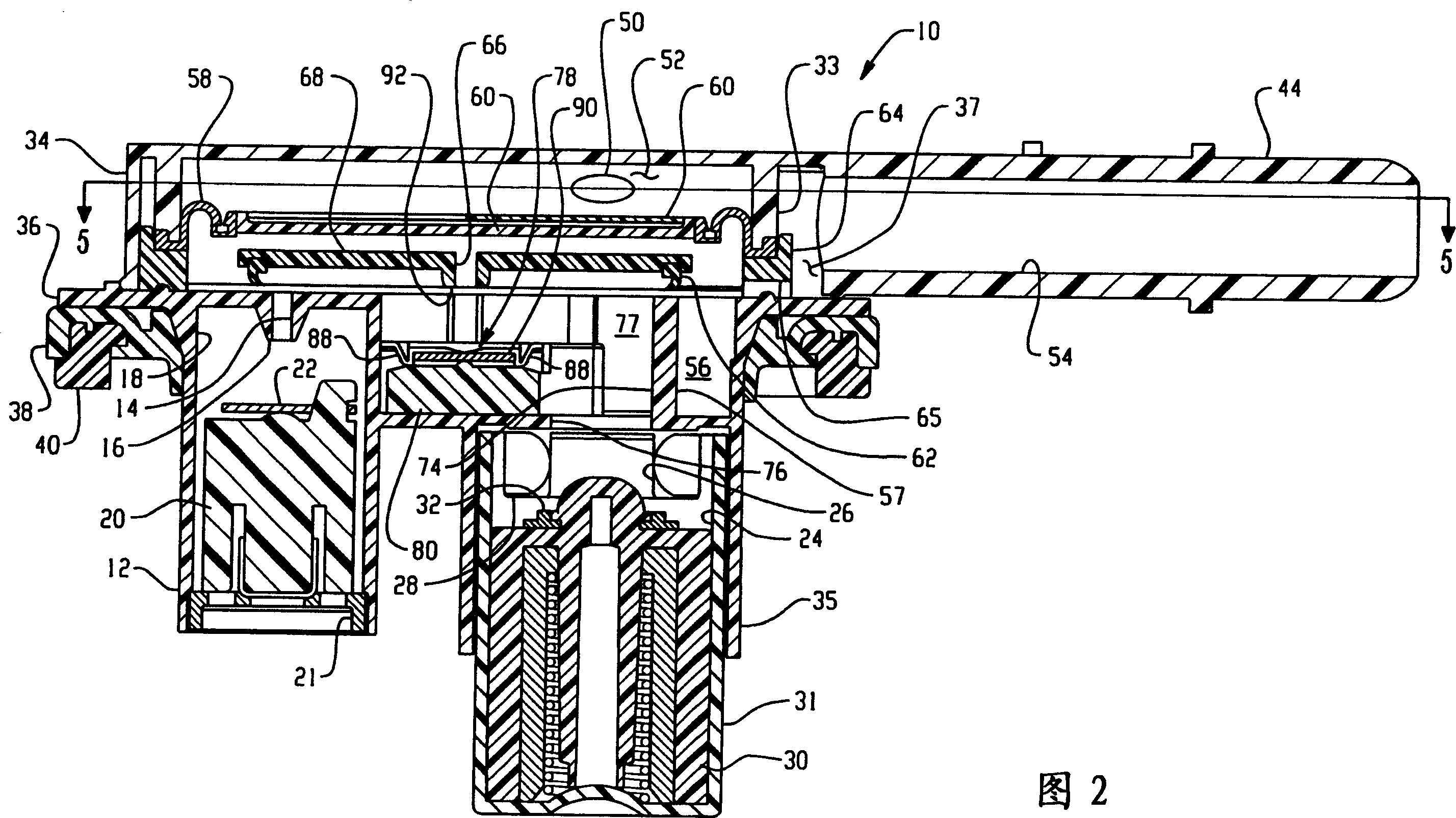

[0016] Referring to Figures 1 to 3, the multifunctional valve assembly, generally indicated at 10, includes a valve body 12 in which is formed a first vapor exhaust passage 14 with a valve seat 16 at the end of the passage 14. The valve seat 16 is arranged in a first position relative to the location of the valve via a mounting hole (not shown) through the wall of the fuel tank, not shown.

[0017] The valve body 12 defines a first float chamber 18 in which is provided a float 20 having a soft elastic valve element 22 arranged at the upper end of the float for raising the float of the valve and resting on the The passage 14 is closed when the valve seat 16 is on.

[0018] The valve body 12 also defines a second valve chamber 24 having a second exhaust passage 26 larger than the passage 14 , the lower end of which forms a valve seat 28 arranged at a lower position relative to the valve seat 16 . A floater assembly 30 is slidably disposed in the valve chamber 24; and, the float...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com