Method for making building architecture of wallboard self-mould cast

A self-mold casting and building structure technology, applied in the field preparation of building components, building components, building structure, etc., can solve the problem of low connection strength between frame and wall, poor wall flatness, low usage area rate problems, to achieve the effect of high construction efficiency, low cost and strong frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments are given below in conjunction with the accompanying drawings to further illustrate how the present invention is realized.

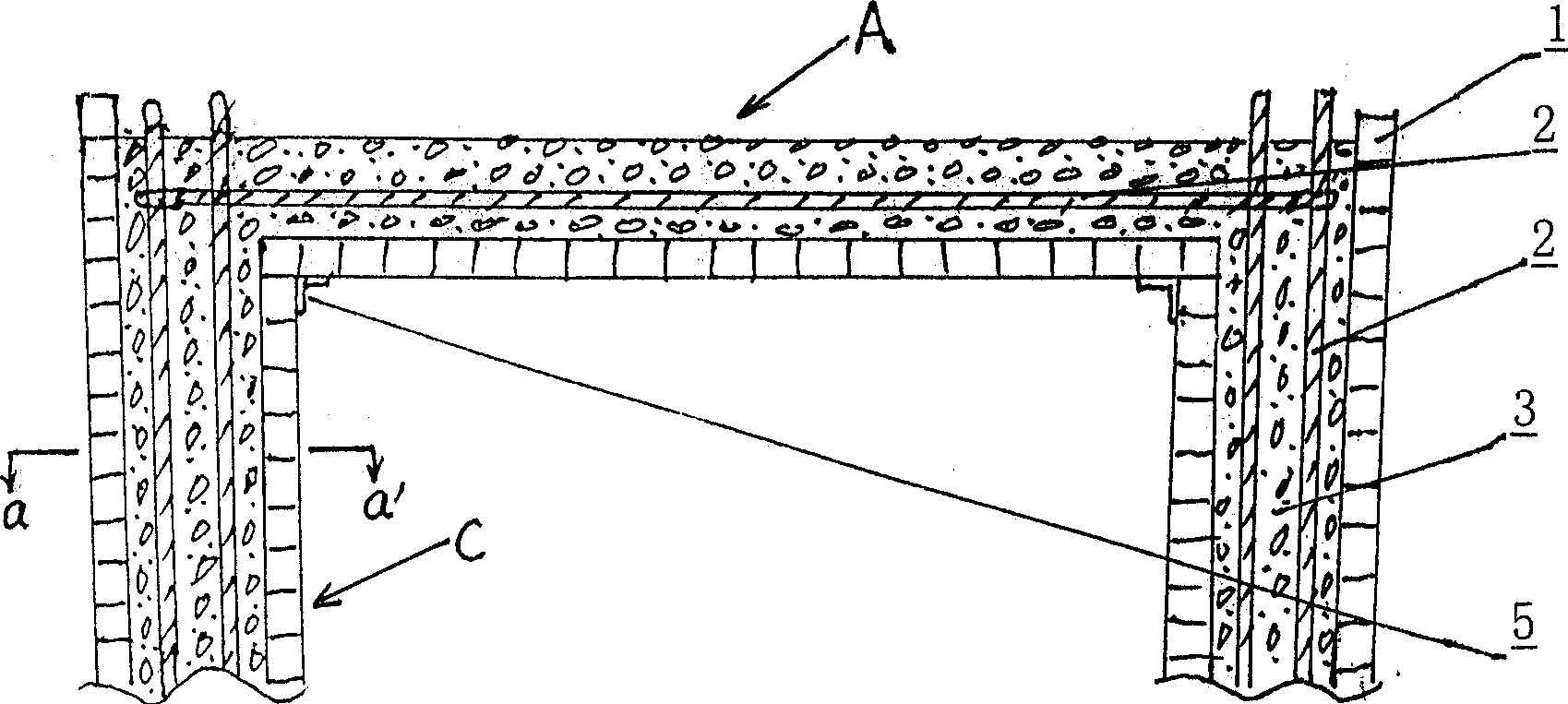

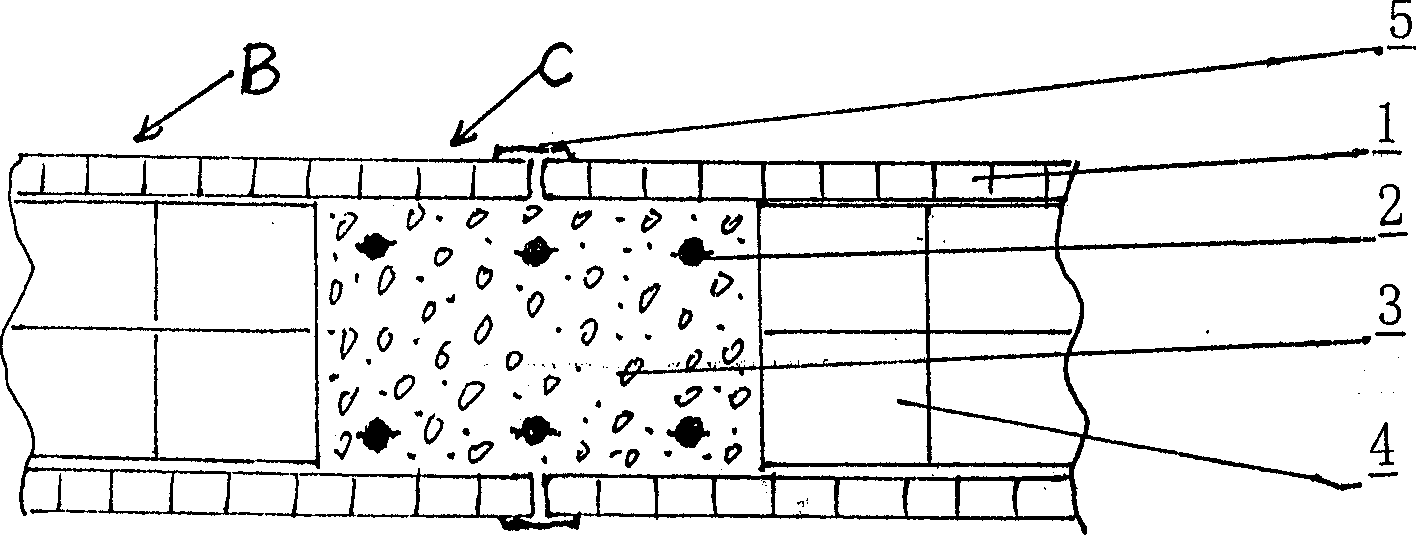

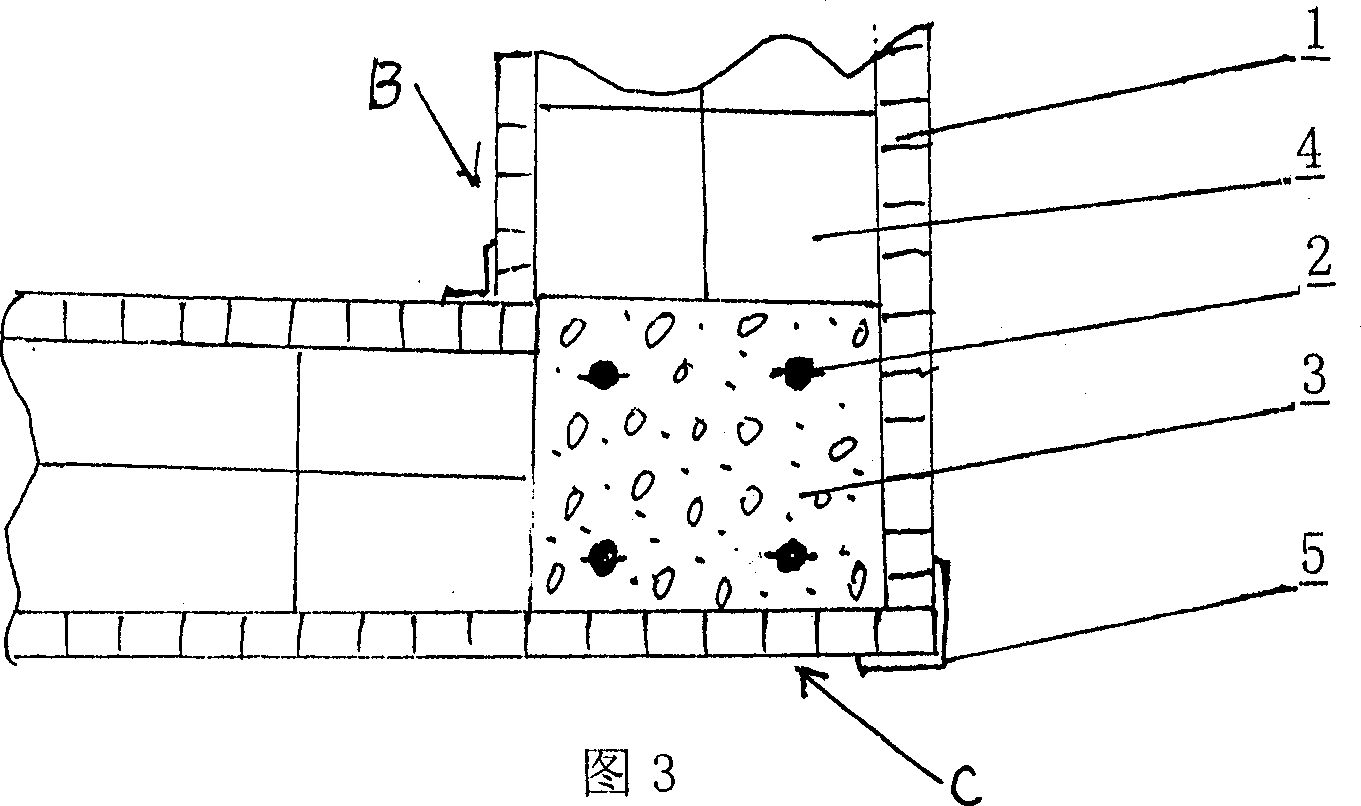

[0015] like figure 1 , figure 2 , shown in Fig. 3, the manufacture method of wallboard self-molding casting building structure, comprises surface layer wallboard 1, directly uses surface layer wallboard 1 as building formwork, forms concrete casting cavity with it, puts steel bar skeleton 2 into cavity , and then cast concrete 3 to form the overall structure.

[0016] The crossbeam A in the building structure is firstly provided with a steel skeleton 2 on the surface wall panel 1, and then casts concrete 3.

[0017] The production of the wall in the building structure is divided into two parts: the pure wall B and the column C. The part of the pure wall B is to put the wall sandwich material 4 in the cavity formed by the surface wallboard 1; the column C The part is to put the reinforcement skeleton 2 in the casting cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com