Negative pressure and environment protection concentration instrument

A concentrator and environmental protection technology, applied in chemical instruments and methods, laboratory utensils, evaporation, etc., can solve problems such as inability to meet environmental protection and save inert purge gas, reduce concentration time, accelerate solvent volatilization, and reduce pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

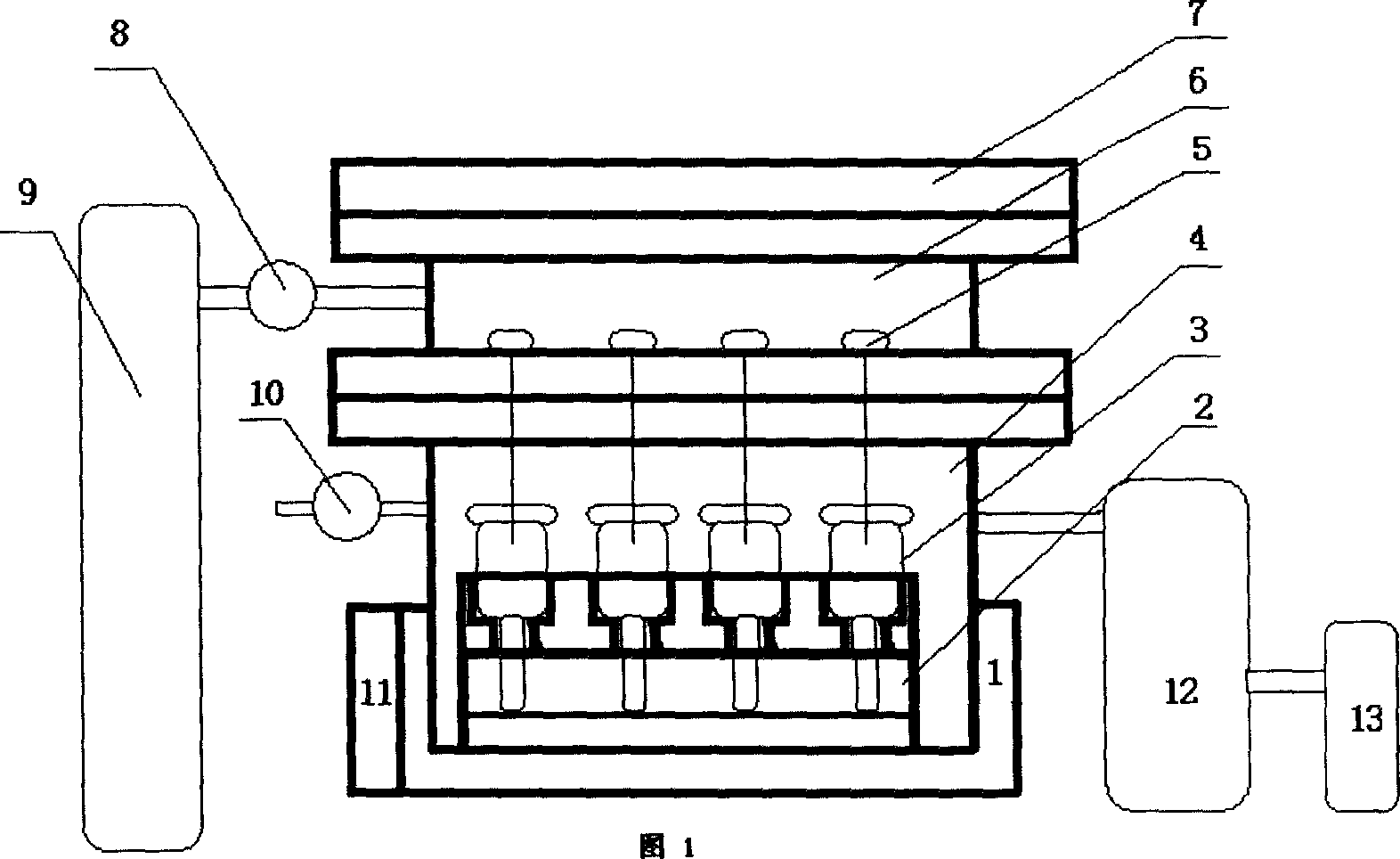

[0010] As shown in Figure 1, the present invention includes a gas distribution system, a sample positioning frame, a heating device, a vacuum system and a solvent recovery system. The air distribution system includes an air source 9, a pressure reducing valve 8, an air distribution cabin cover 7, an air distribution cabin 6 and a thin air blowing tube 5, the heating device includes a temperature control device 11 and a water bath 1, and the sample positioning frame is provided with a sample fixing frame 2 1. A graduated sample concentrator 3 is arranged on the sample holder, and the vacuum system includes a vacuum pump 12 , a vacuum chamber 4 and a vent valve 10 . The connection structure of the equipment is shown in the figure. The air source 9 and the pressure reducing valve 10 are connected to the side of the air distribution cabin 6. The upper surface of the air distribution cabin is open. 7 is located at the gas distribution cabin 6 upper ends. The gas distribution chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com