System of detecting state and failure diagnosis of oil well drill pump

A technology of fault diagnosis and state detection, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., to achieve the effect of high power, harsh working conditions and high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

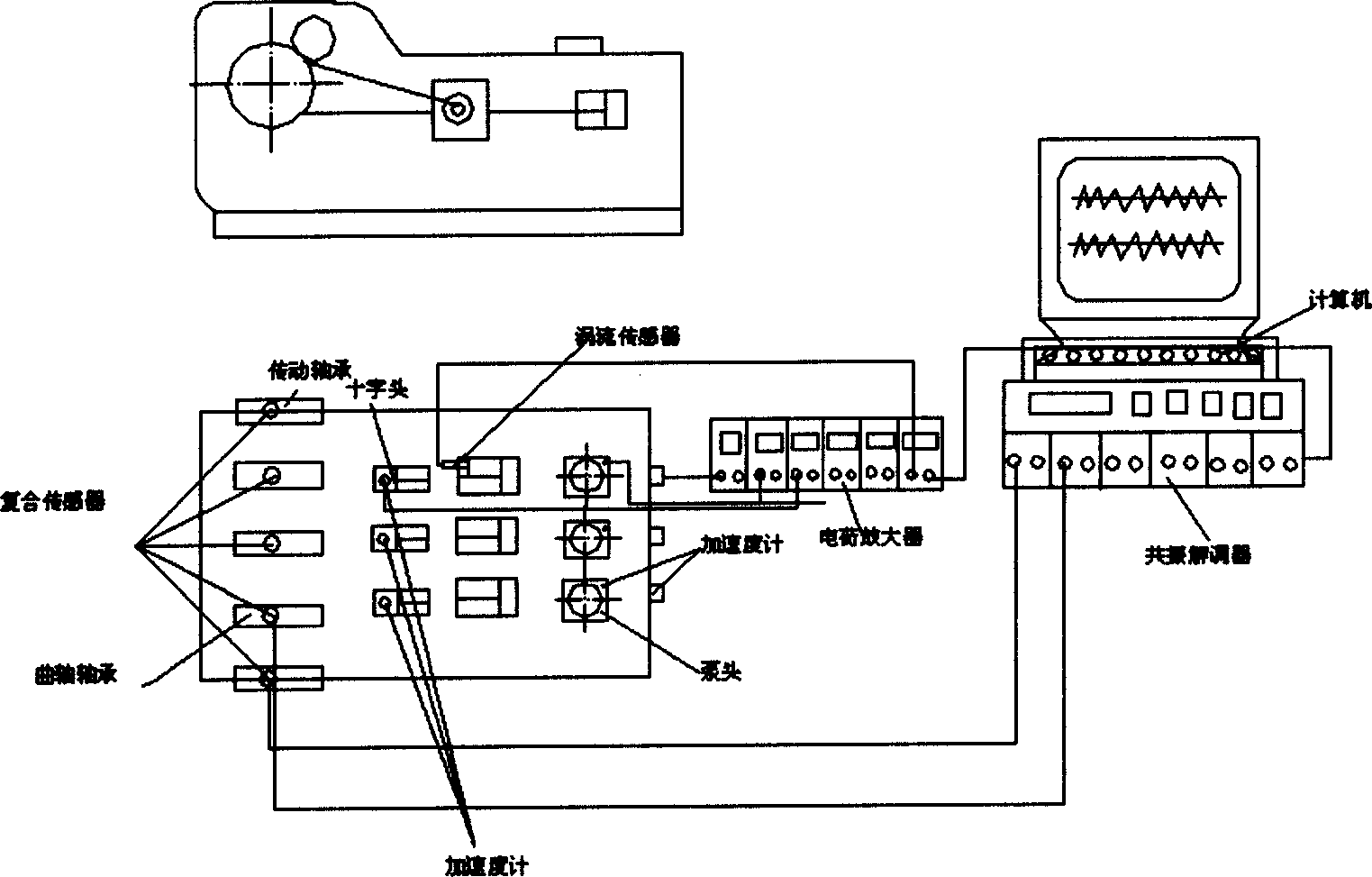

[0014] This system will be further described below with reference to the accompanying drawings. The invented software system, aiming at the actual conditions of the power end and fluid end of the drilling pump, combined with the experimental research work, adopts different signal analysis and processing methods on a complete vibration test platform (see Figure 1). Specifically:

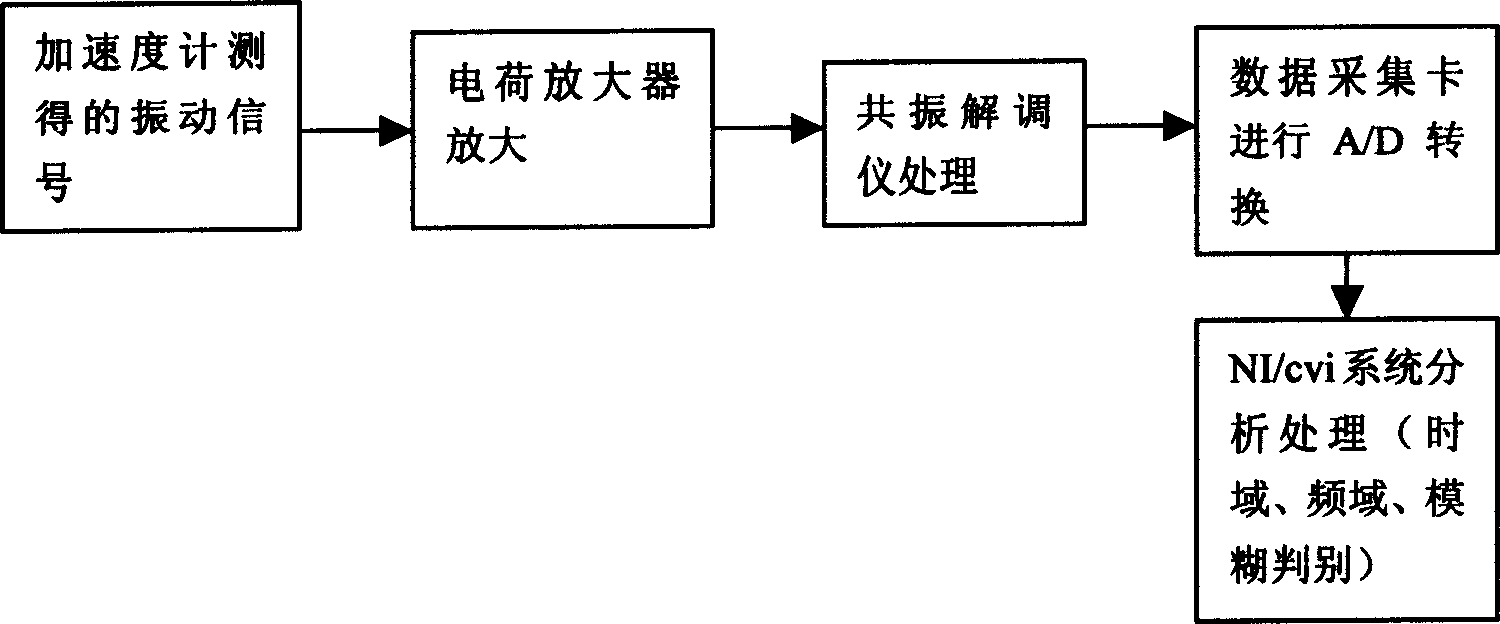

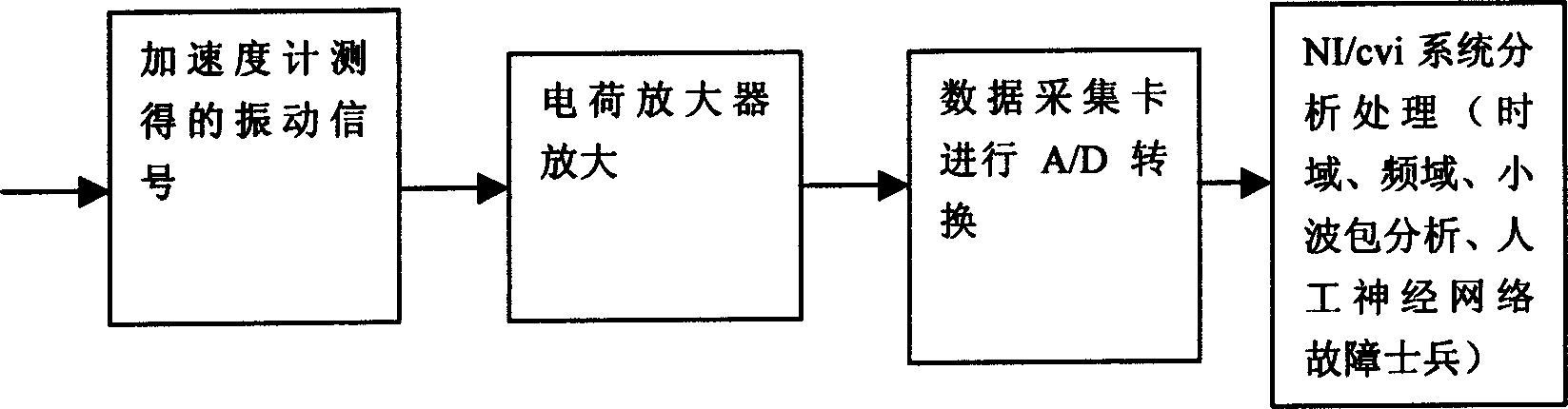

[0015] For the power end, the method shown in Figure 2 will be adopted for processing and analysis. Its purpose is to reduce noise interference and make the fault characteristic spectrum line stand out obviously, so the comprehensive analysis method of spectrum analysis, resonance demodulation and fuzzy identification is adopted. By analyzing the amplitude domain and frequency domain of the resonant demodulated wave, the magnitude and type of the fault can be determined. However, because there is a certain gap between the actual operating conditions of the bearing and the assumed conditions in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com