Active, dyestuff modified bath dyeing technology

A reactive dye technology, applied in the field of reactive dye denaturation bath dyeing, can solve the problems of loss of dyeing ability of fibers containing -OH groups, low dye utilization rate, large amount of sewage, etc., to improve dyestuff utilization rate and reduce dyeing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

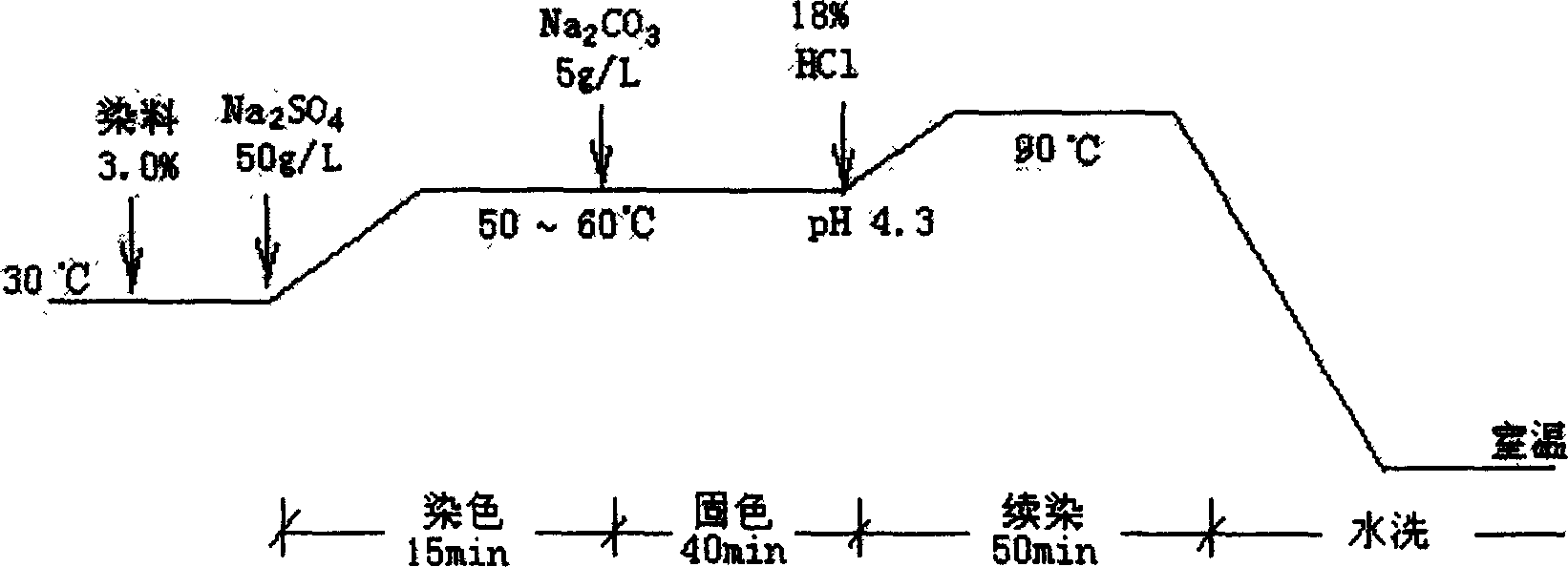

Embodiment 1

[0035] Embodiment 1: Soybean protein / PVA blended fiber tops Cibacron FN reactive dye denaturation bath dyeing and dyeing: Cibacron FN dyestuff consumption 3.0% (owf); Accelerator Yuanming powder 50g / L or salt 15g / L salt; Dyeing temperature 50~60℃; dyeing time is 15min.

[0036] Color fixing: the amount of color fixing agent sodium carbonate is 5g / L; the color fixing time is 40min. Keep the original dyeing bath temperature constant.

[0037] Denaturation: Add 18% hydrochloric acid solution to the dye bath to reduce the pH value of the dye bath to 4.3.

[0038] Continued dyeing: raise the dyeing temperature to 90°C and continue dyeing for 50 minutes.

[0039] Washing:

[0040] see attached figure 2 :

[0041] Dyeing effect:

[0042] Basic dyeing percentage: 65.7%

[0043] Total uptake percentage: 70.4%

[0044] Fixation percentage: 55.6%

[0045] Fixation efficiency: 78.9%

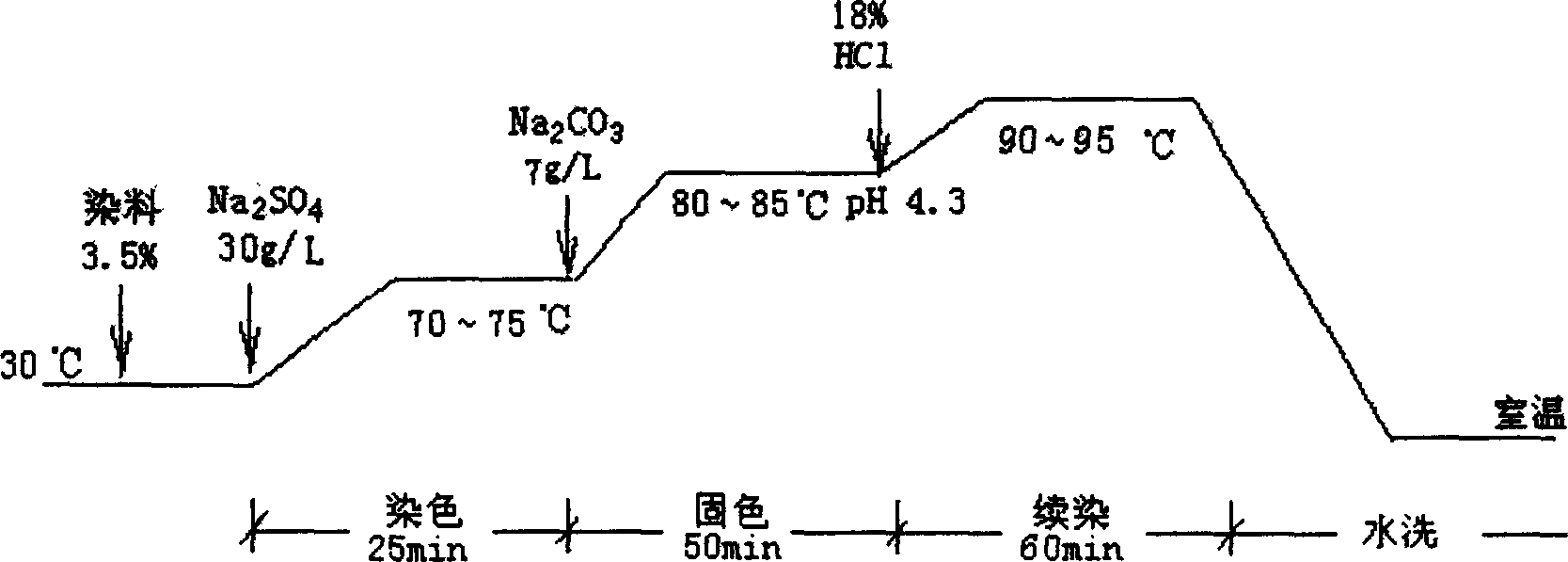

Embodiment 2

[0046] Embodiment 2: Soybean protein / PVA blend fiber plain weave woven fabric Cibacron LS reactive dye denaturation bath dyeing and dyeing: Cibacron LS dyestuff consumption 3.0% (owf); Accelerator Yuanming powder 30g / L; Dyeing temperature 70~75 ℃ ; Dyeing time is 25min.

[0047] Color fixing: the amount of color fixing agent sodium carbonate is 7g / L; the color fixing time is 50min. The temperature is 80-85°C.

[0048] Denaturation: Add 18% hydrochloric acid solution to the dye bath to reduce the pH value of the dye bath to 4.3.

[0049] Continued dyeing: raise the dyeing temperature to 90-95°C, and continue dyeing for 60 minutes.

[0050] Washing:

[0051] see attached image 3 :

[0052] Dyeing effect:

[0053] Basic dyeing percentage: 70.1%

[0054] Total uptake percentage: 88.3%

[0055] Fixation percentage: 73.0%

[0056] Fixation efficiency: 82.8%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com