Semiconductor device and method for fabricating the same

A semiconductor and device technology, which is applied in the field of semiconductor devices and semiconductor device manufacturing, can solve the problems that it is difficult to reliably prevent the dielectric film from being damaged, and the dielectric film reduces the manufacturing output, so as to prevent the reduction of QSW, good electrical characteristics, and good The effect of coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

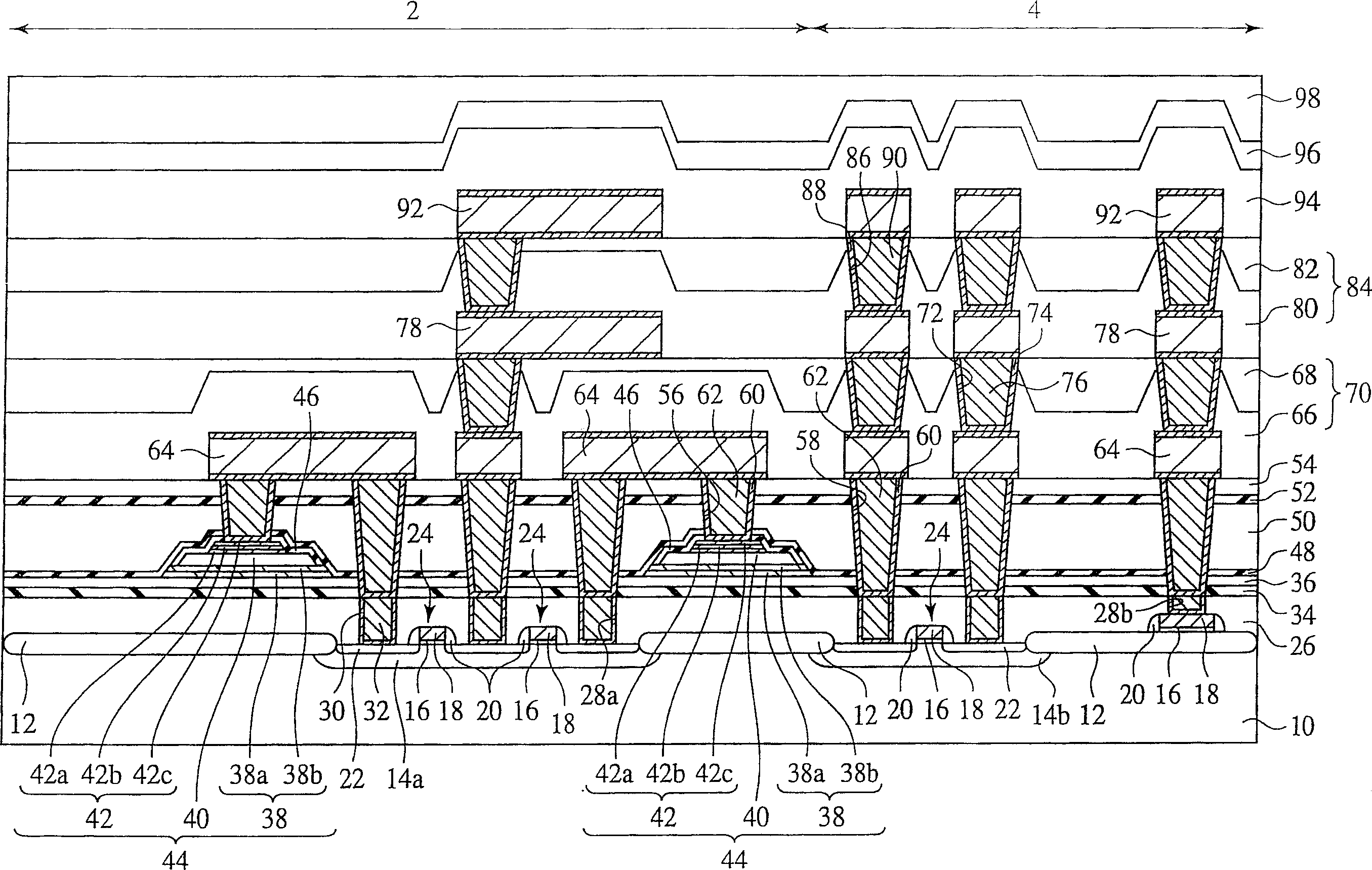

[0067] The following will combine Figure 1 to Figure 22 The semiconductor device according to the first embodiment of the present invention and a method of manufacturing the semiconductor device are explained.

[0068] Semiconductor device

[0069] First, combine figure 1 To FIG. 4, the semiconductor device according to the present embodiment is explained. figure 1 It is a cross-sectional view of the semiconductor device according to this embodiment. in figure 1 In the figure, the memory cell area 2 is shown on the left side of the figure, and the peripheral circuit area 4 is shown on the right side of the figure.

[0070] Such as figure 1 As shown, a device isolation region 12 defining a device region is formed on a semiconductor substrate 10 such as silicon. Wells 14a and 14b are formed in the semiconductor substrate 10 in which the device isolation region 12 is formed.

[0071] A gate electrode (gate line) 18 is formed on the semiconductor substrate 10 on which the wells 1...

no. 2 example

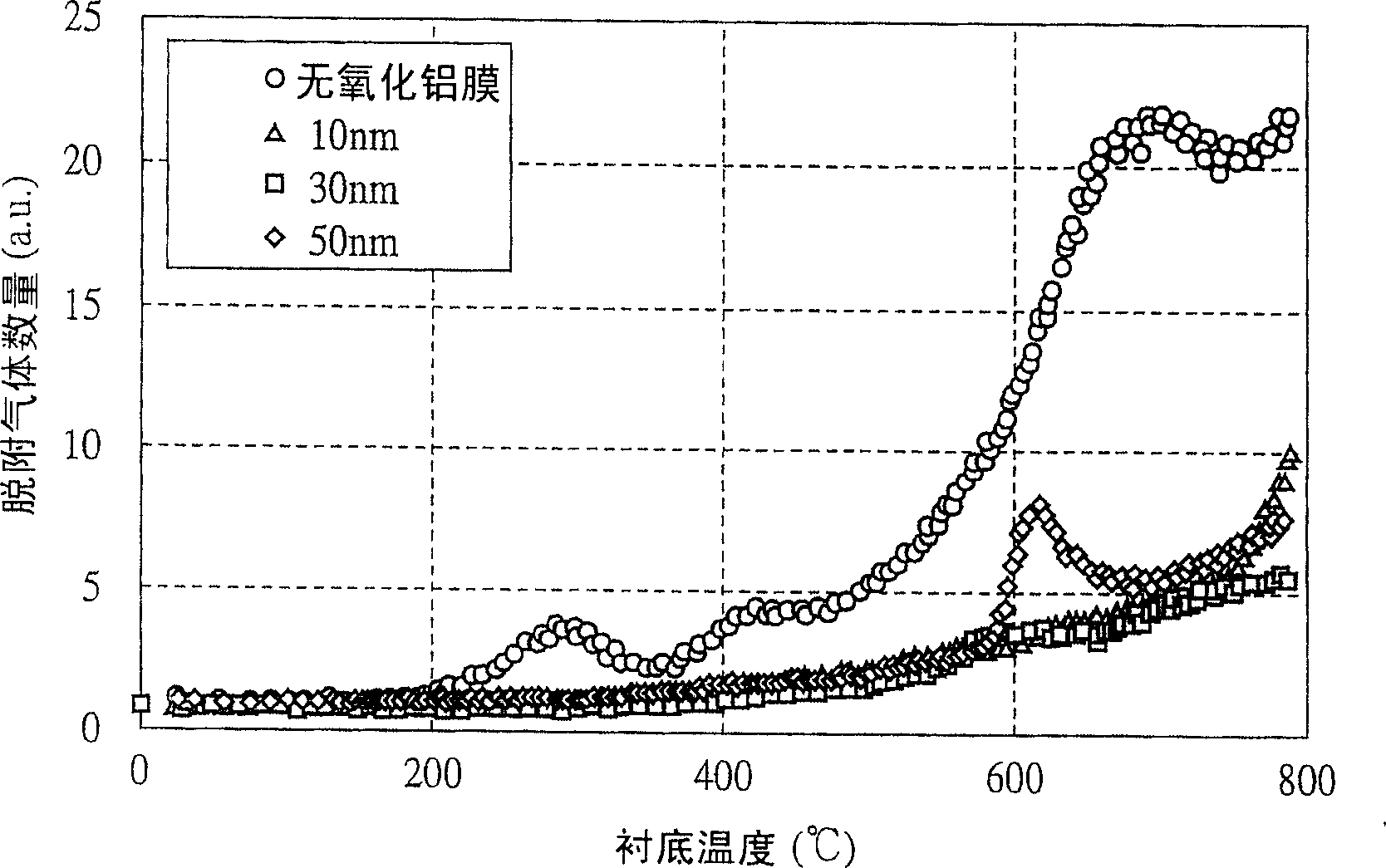

[0314] As described above, a flat barrier film (hydrogen diffusion preventing film) 52 for blocking the diffusion of hydrogen and water is formed on the capacitor, so that hydrogen and water can be surely prevented from reaching the capacitor 44.

[0315] However, when the barrier film 52 is simply formed, the exchange charge quantity Q of the capacitor 44 SW Usually reduced. The exchange charge quantity Q of the capacitor 44 SW This reduction is due to the large stress acting on the capacitor 44 when the ferroelectric film 40 forming the barrier film 52 and the barrier capacitor 44 is polarized.

[0316] The inventor of the present application conducted serious research and came up with a hydrogen / water diffusion preventing film with a function of blocking hydrogen and water diffusion and a stress relief layer for reducing the stress of the hydrogen / water diffusion preventing film to form a barrier film. The hydrogen / water diffusion preventing film for preventing the diffusion of...

no. 3 example

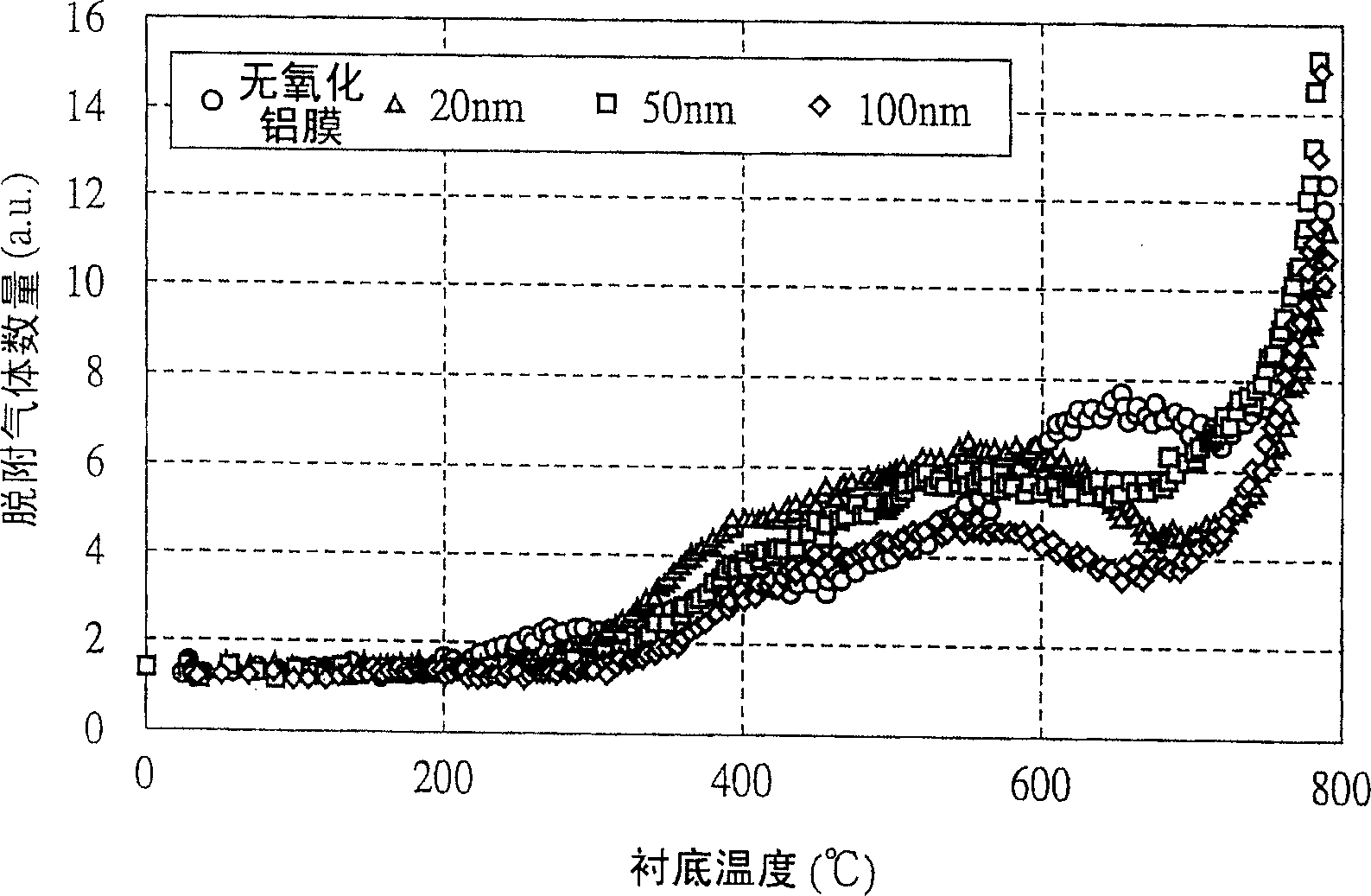

[0442] Next, a semiconductor device according to a third embodiment of the present invention and a method of manufacturing the semiconductor device will be explained with reference to FIGS. 35 to 37. FIG. 35 is a cross-sectional view of the semiconductor device according to the present embodiment. Figure 1 to Figure 34 The same components in the illustrated semiconductor devices and methods of manufacturing the semiconductor devices according to the first and second embodiments are represented by the same reference numerals, and the explanation of these reference numerals will not be repeated or simplified.

[0443]The main feature of the semiconductor device according to the present embodiment is that a plurality of hydrogen / water diffusion preventing films are stacked on each other with an intermediate layer formed therebetween, thereby forming a barrier film.

[0444] As shown in FIG. 35, a hydrogen / water diffusion preventing film 52 having a function of preventing the diffusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com