Lighting device support structure of drum washing machine knob mechanism

A technology of a drum washing machine and a support structure, applied in the field of washing machines, can solve the problems of unpreventable, unpreventable damage, light leakage, etc., and achieve the effects of improving trust, restraining shaking, and protecting the joint part.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

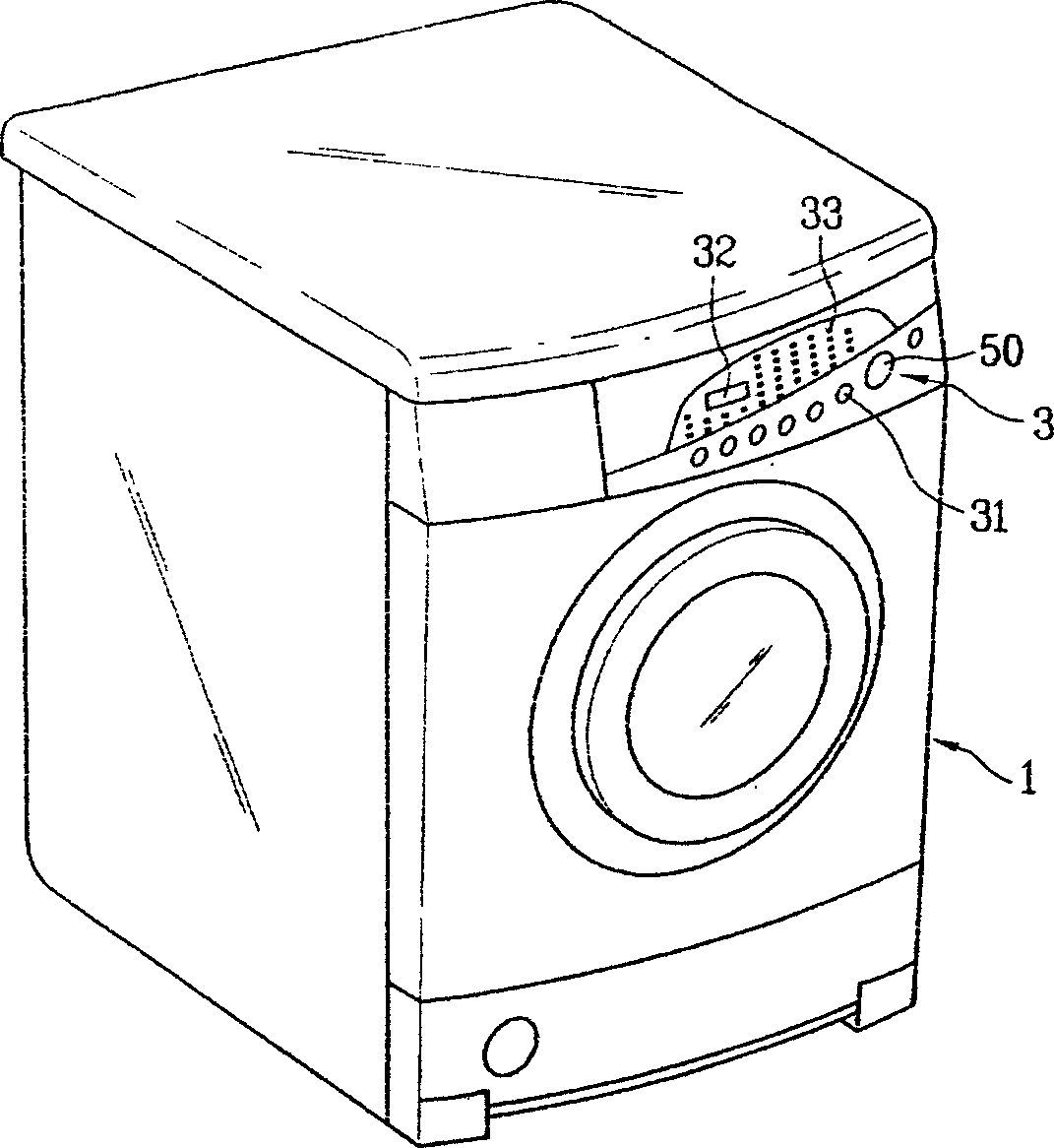

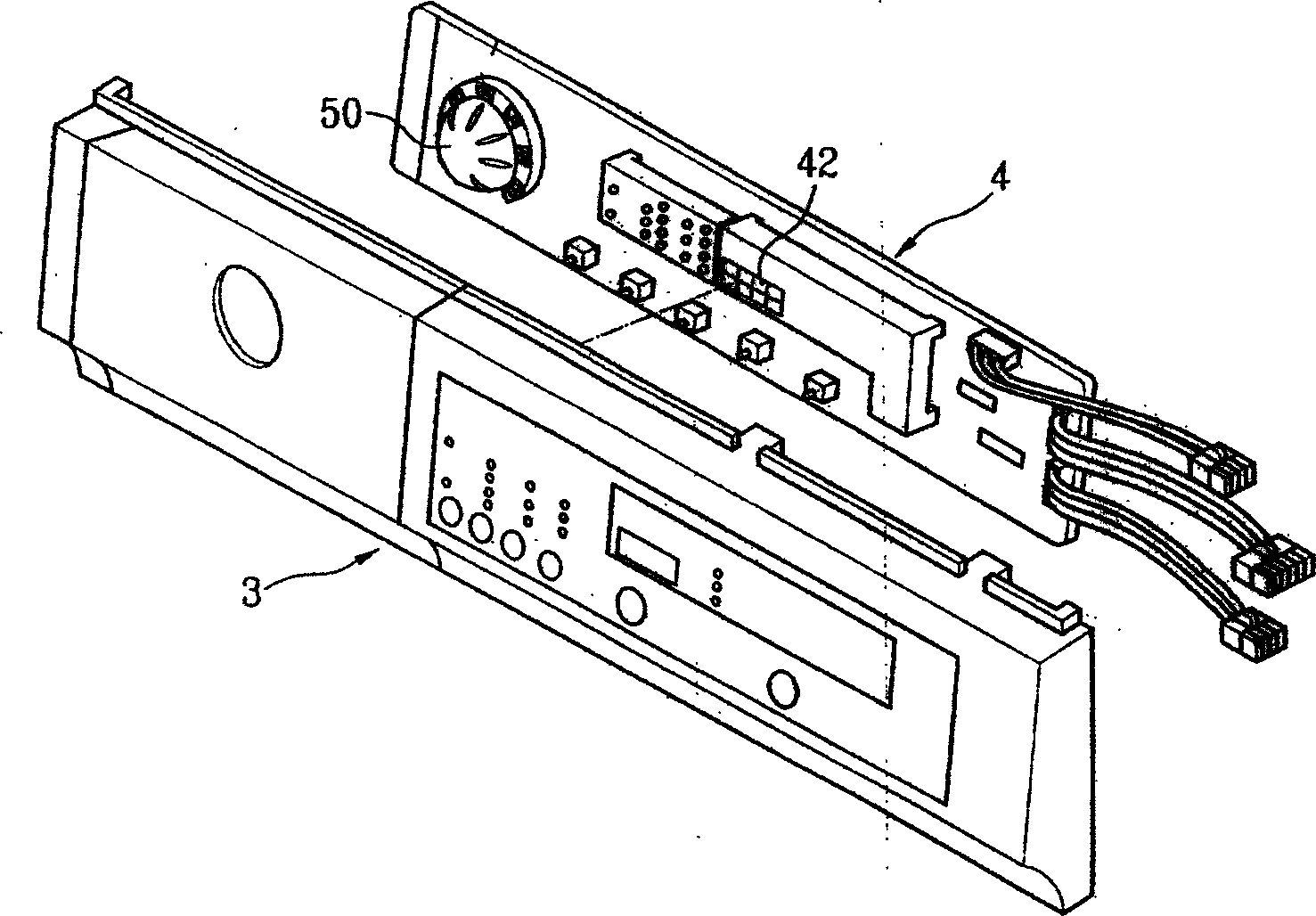

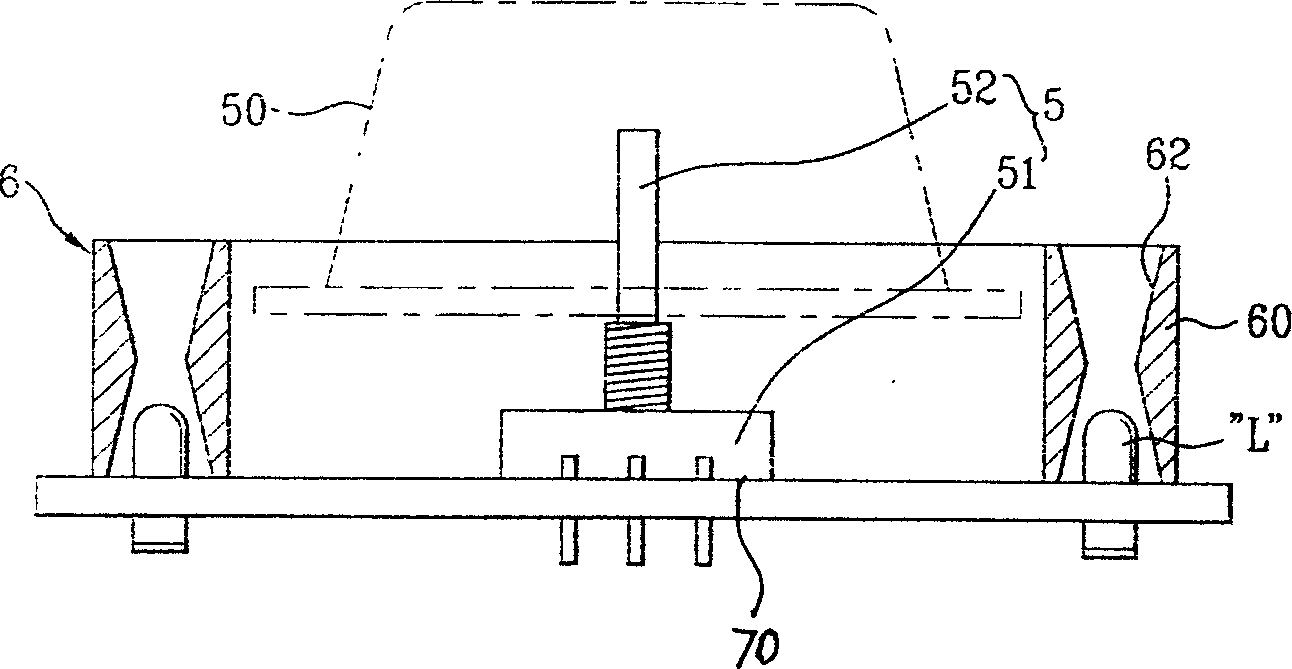

[0038] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail: Figure 5 It is a sectional view of the knob mechanism of the present invention. Image 6 express Figure 5 Plan view of the illuminator bracket in .

[0039] As shown in the figure, the knob mechanism of the drum washing machine of the present invention is composed of a rotary switch 5 , a knob 50 , and an annular illuminator bracket 6 .

[0040] The rotary switch 5 is composed of an encoder 51 fixed on the circuit board 70 and an encoder shaft 52 connected to the encoder 51; the knob 50 is combined with the encoder shaft 52 of the rotary switch 5; the illuminator bracket 6 encloses the knob 50 and fixed on the circuit board 70.

[0041] In the knob mechanism of the drum washing machine of the present invention composed of many components, the inner side of the main frame 60 of the illuminator bracket 6 has a supporting flange 61, and the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com