Digital-control servo system and its control for permanent magnet synchronous motor without bearing

A permanent magnet synchronous motor and servo system technology, applied in synchronous machines, electrical components, electromechanical devices, etc., can solve the problem of no patents and literature, and achieve the effects of reducing volume and power consumption, reducing length, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

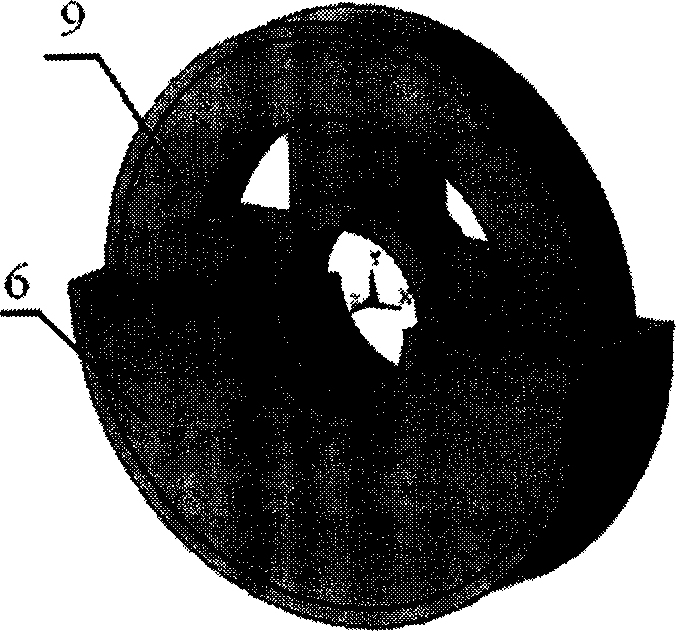

[0032] The control method adopted is a five-degree-of-freedom bearingless permanent magnet synchronous motor CNC servo system prototype body composed of a two-degree-of-freedom bearingless permanent magnet synchronous motor (21) and a three-degree-of-freedom radial-axial hybrid magnetic bearing (22). , using a linear closed-loop controller (30) to control the radial-axial position of the three-degree-of-freedom hybrid magnetic bearing; adjusting the control parameters of the position PID controller (31, 32, 33) to realize the three-degree-of-freedom radial-axial hybrid The magnetic bearing works stably; the Hall sensor (15) is used to detect the size of the rotor magnetic field, and the radial displacement and the motor speed are dynamically decoupled and controlled using a rotor field-oriented control strategy based on a two-degree-of-freedom bearingless permanent magnet synchronous motor; by adjusting the position control The parameters of two PI controllers (71, 72) and two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com