Optical thin-membrane production of dispersion oxide from copper-golden nanometer particle

A technology of oxide thin film and nano particles, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of copper-gold dispersed oxide composite thin film system that have not been reported, and achieve excellent nonlinear characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

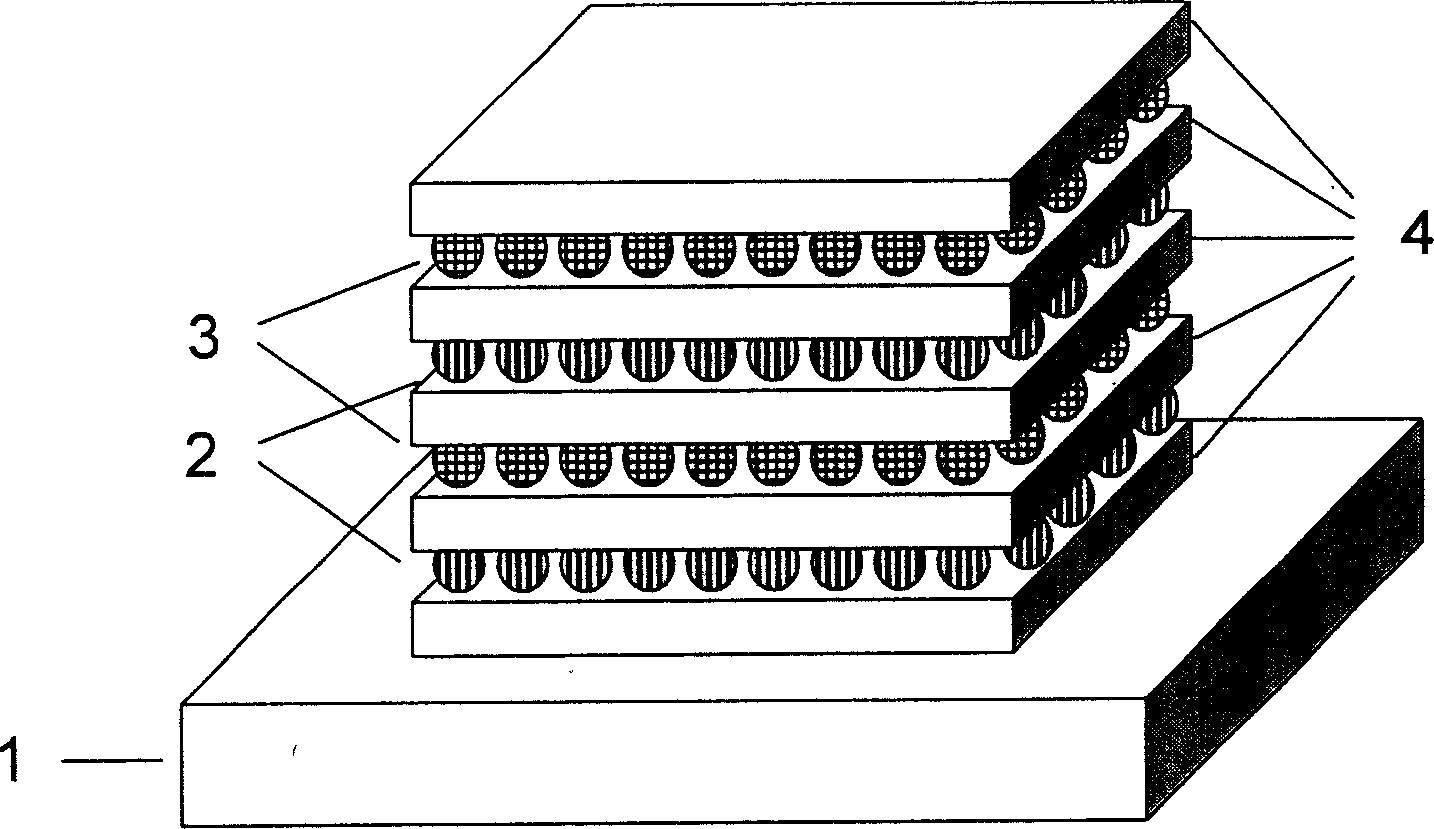

[0013] Cu of the present invention x Au 1-x / SiO 2 The copper-gold nanoparticles dispersed oxide multilayer film of the system is composed of several layers or even hundreds of layers of copper-gold nano-metal particle layers and oxides. The diameter of copper-gold nanoparticles is 2-100 nanometers, and the thickness of the oxide layer is several nanometers. to tens of nanometers. figure 1 Schematic diagram of the nano-metal particle dispersed oxide multilayer film designed for the present invention. Wedge 1 is the substrate, wedges 2 and 3 are Cu or Au nanoparticle layers, respectively, and wedge 4 is the oxide layer. The thin film is prepared by sputtering technique.

[0014] Its specific technological process is:

[0015] 1. Cu, Au and SiO 2 The sputtering target has a diameter of 50mm and a purity of 99.99%.

[0016] 2. Clean the quartz substrate ultrasonically in acetone for 5-10 minutes, and then put it into the sputtering chamber.

[0017] 3. The substrate press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com