Method for preparing optical thin film with gold silver nanometer particle and dispersal oxide

A nanoparticle and optical film technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of rare gold-silver composite metal particle dispersed oxide film, achieve excellent nonlinear characteristics, dispersion uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

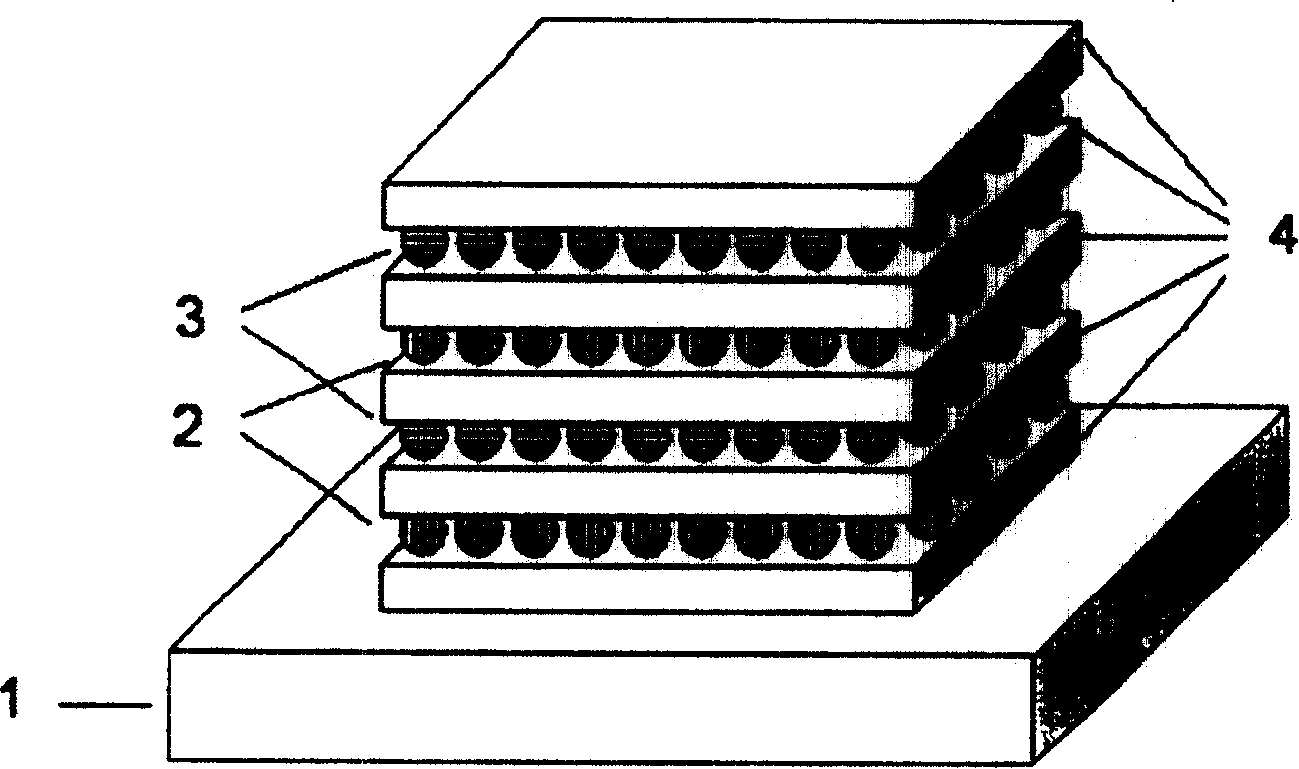

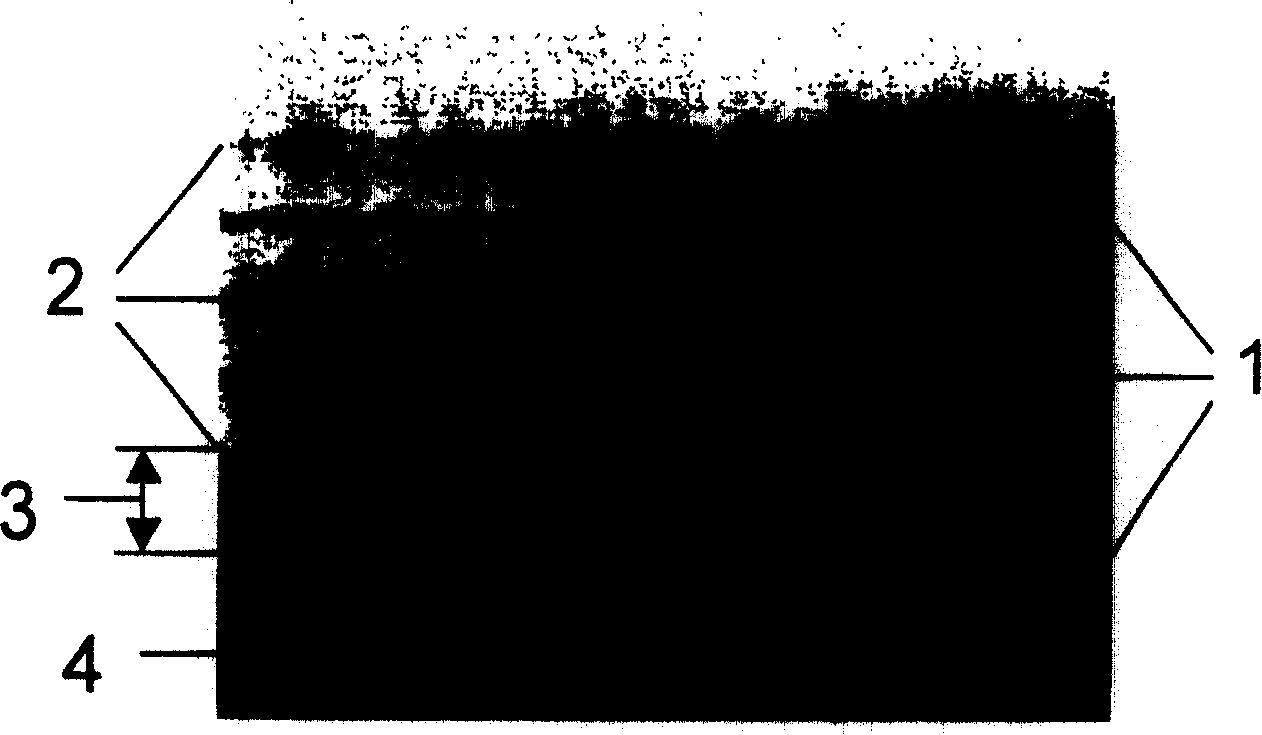

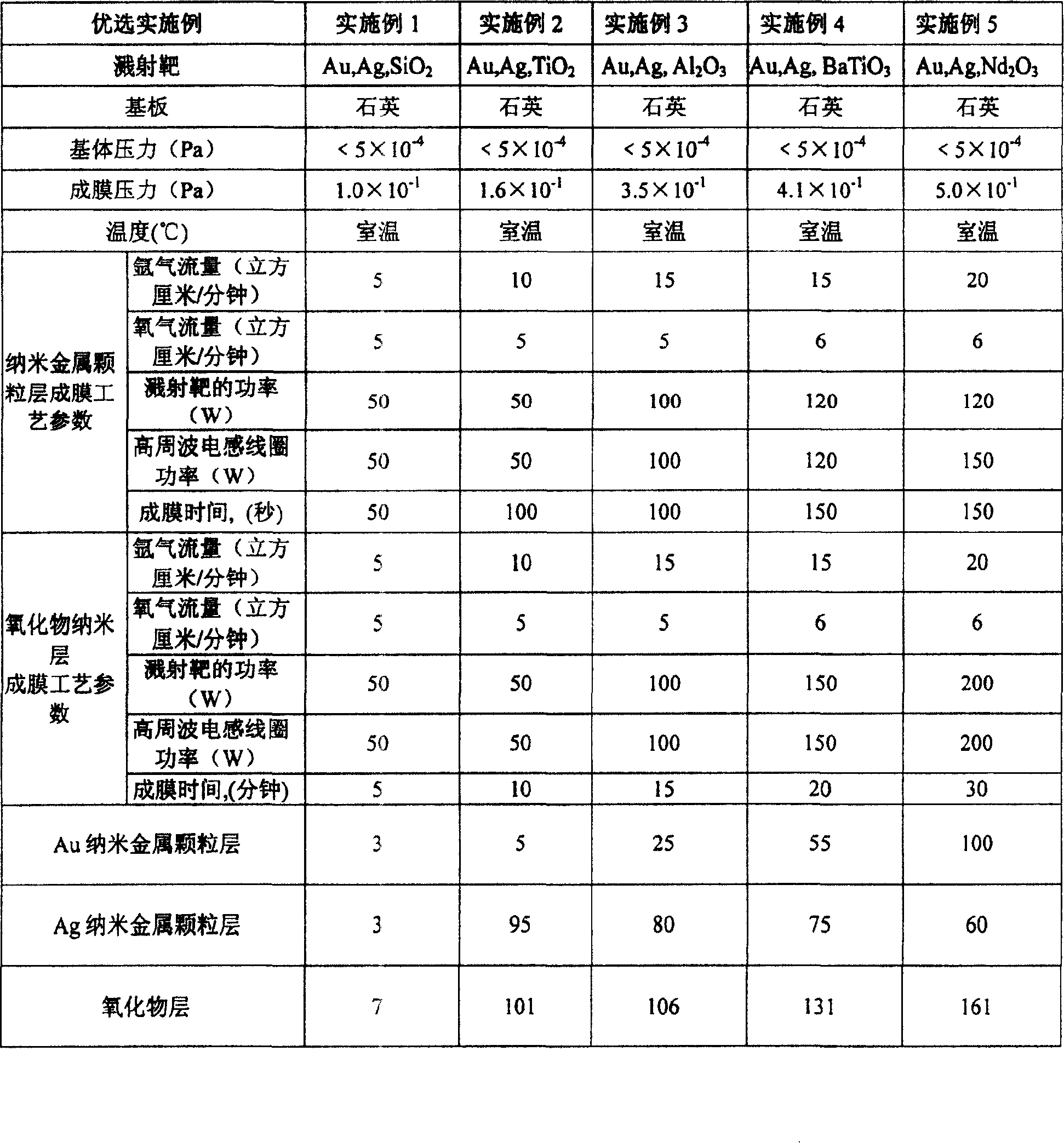

[0014] Au of the present invention x Ag 1-x / SiO 2 The gold and silver nanoparticles dispersed oxide multilayer film of the system is composed of several layers or even hundreds of layers of gold and silver nano metal particle layers and oxides. The diameter of gold and silver nanoparticles is 2-50nm, and the thickness of the oxide layer is several nanometers to tens of nanometers. figure 2 Represents the nano-layered morphology of the gold-silver multilayer film (the Au nanoparticle layer is 3 layers, the Ag nanoparticle layer is 3 layers, and the SiO nanoparticle layer is 3 layers. 2 Layer is 7 layers) cross-sectional transmission electron micrographs. Such as figure 2 As shown, the nano-metal particle layer is completely parallel and evenly spaced in a large area, and the thickness of the entire film is 70nm. Of which SiO 2 The thickness of the layer is 10 nm and the diameter of the gold and silver nanoparticles is 6-8 nm. The thin film is prepared by sputtering te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com