Production of nanometer heater for tumor magnetic thermal therapy

A heat-generating agent and nanotechnology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problem of not paying attention to the volume of the reaction system, reduce the magnetic dipole interaction, improve the heating effect, and reduce equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

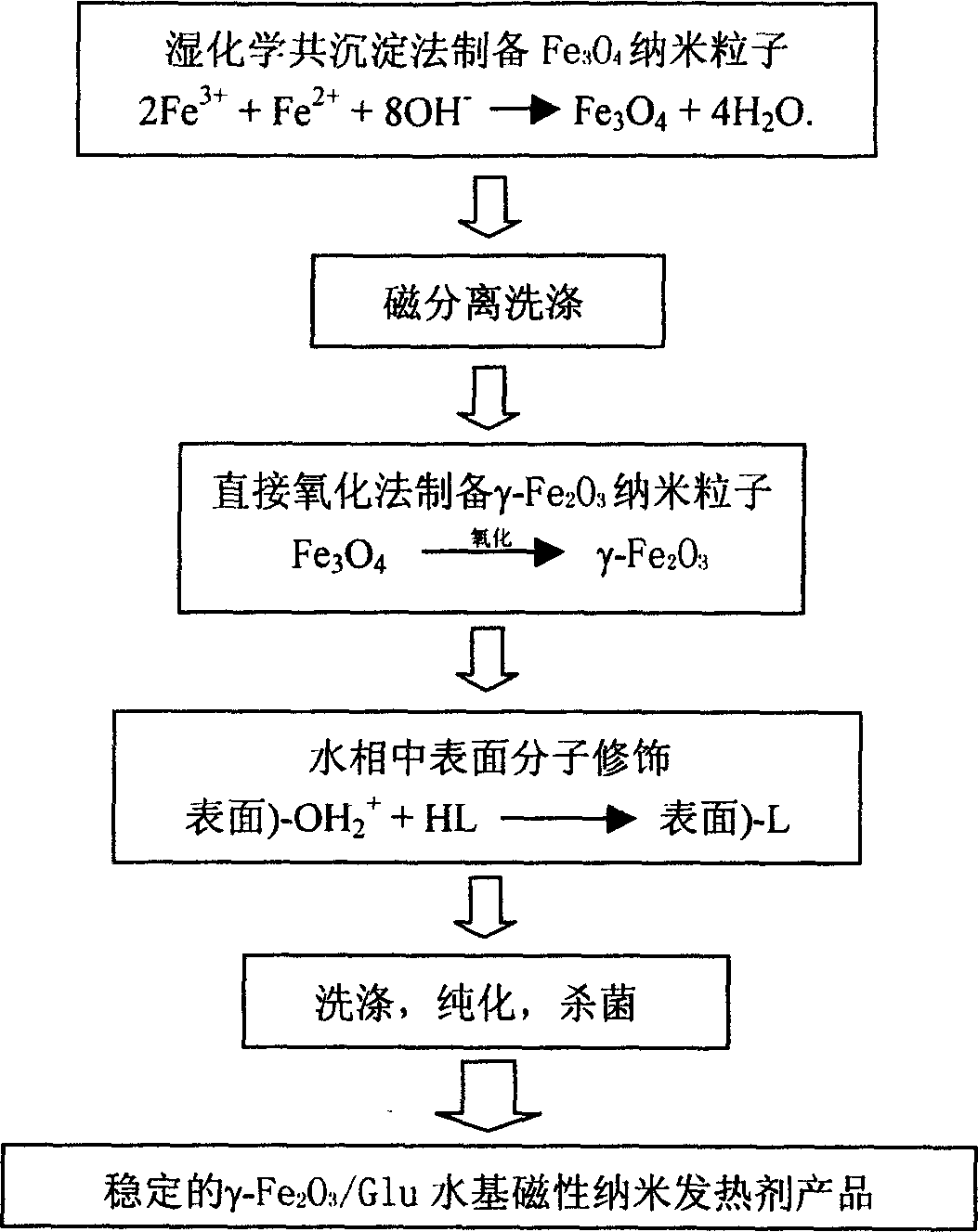

Method used

Image

Examples

Embodiment Construction

[0024] step 1):

[0025] Preparation of Fe by wet chemical co-precipitation method 3 o 4 Nanoparticles, the reaction is carried out in a 1-liter beaker or a 5-liter beaker or a 50-liter high-speed stirring reactor, and the reaction raw material is FeCl 3 and FeSO4 Press Fe 3+ / Fe 2+ = Mix at a certain ratio between 1.4-1.7 and add to the beaker or reactor, under stirring conditions, add 2.5% ammonia solution into the beaker or reactor through the addition funnel to chemically react with the iron salt until pH = 9, stop adding Ammonia, continue to stir for 1 h and then stop the reaction, and protect the whole reaction process with nitrogen gas.

[0026] Step (2):

[0027] Prepared Fe 3 o 4 Nanoparticles, after washing 3-4 times by magnetic separation, diluted with water to 2-4 g / l water-based Fe 3 o 4 The magnetic liquid is then oxidized with air at 90-100°C, pH = 2-3, and stirred for 4-5 hours to form a water-based γ-Fe 2 o 3 magnetic fluid.

[0028] Step (3):

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com