Ultraviolet radiant sensor system with sterilizer

A technology for sterilization and disinfection devices and sensing systems, which is applied in the field of optical sensing systems, can solve the problems of reduced sensor sensitivity, accumulated dirt, and decreased ability of sensors to detect ultraviolet radiation, so as to reduce the loss of water pressure head and promote maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

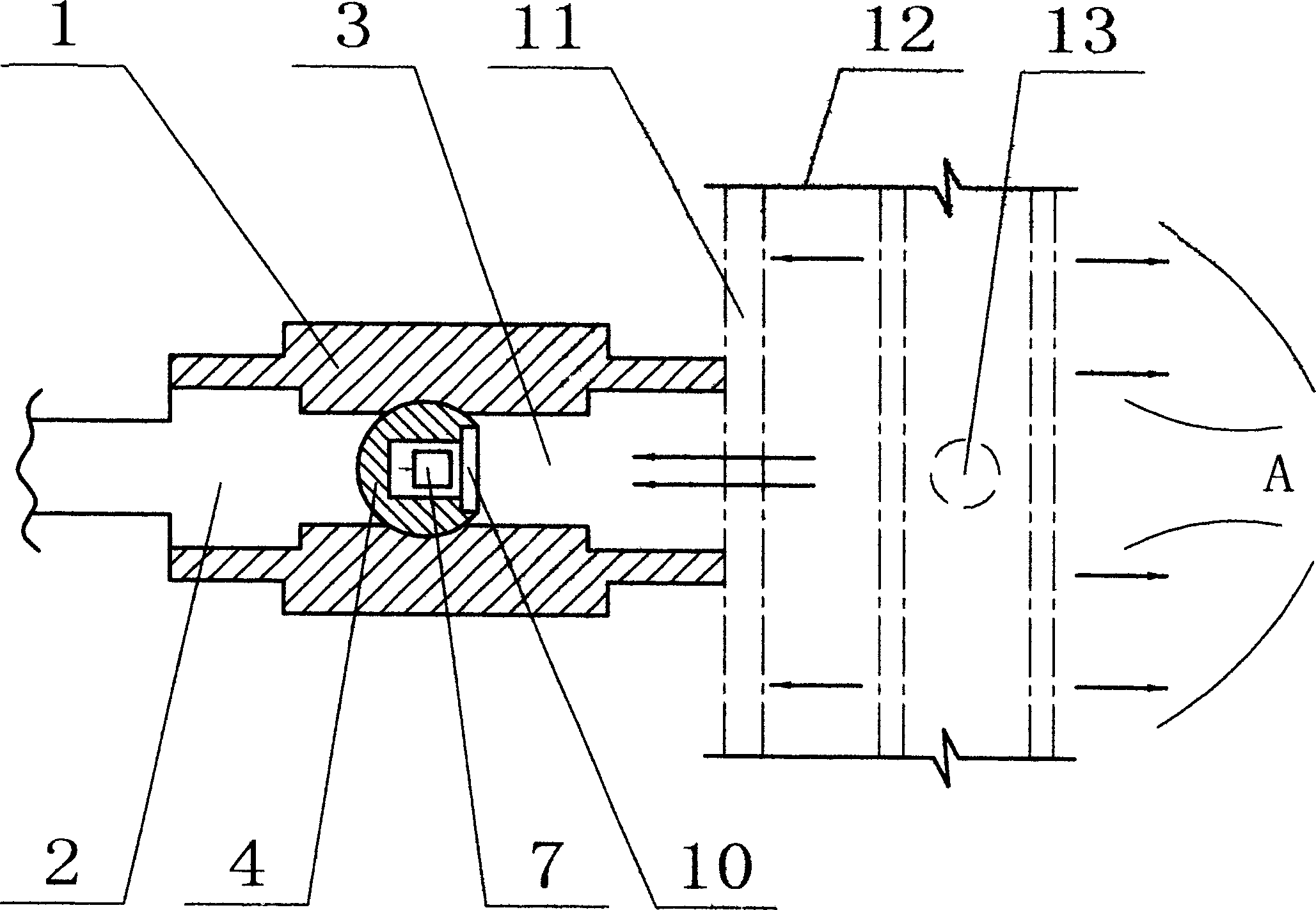

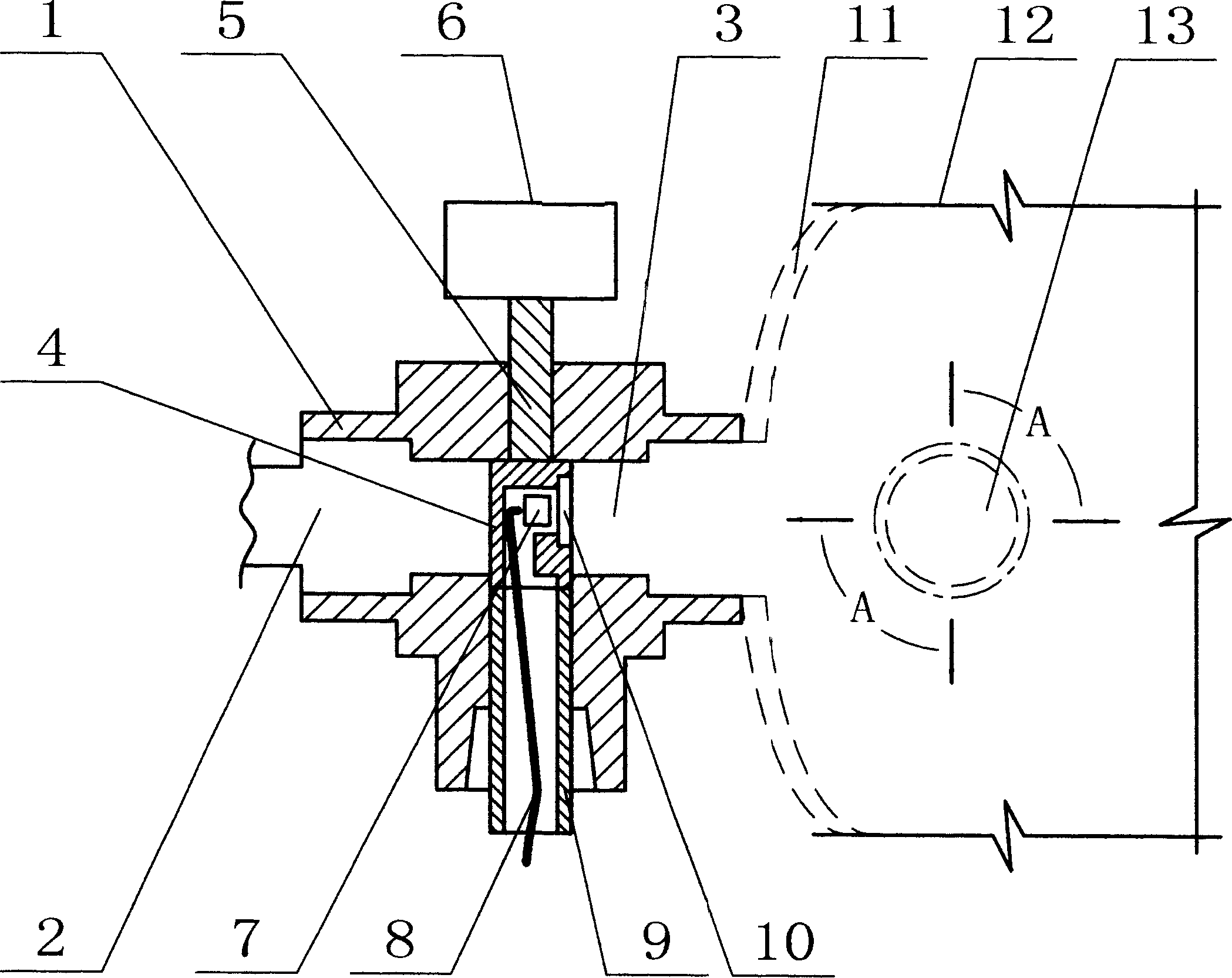

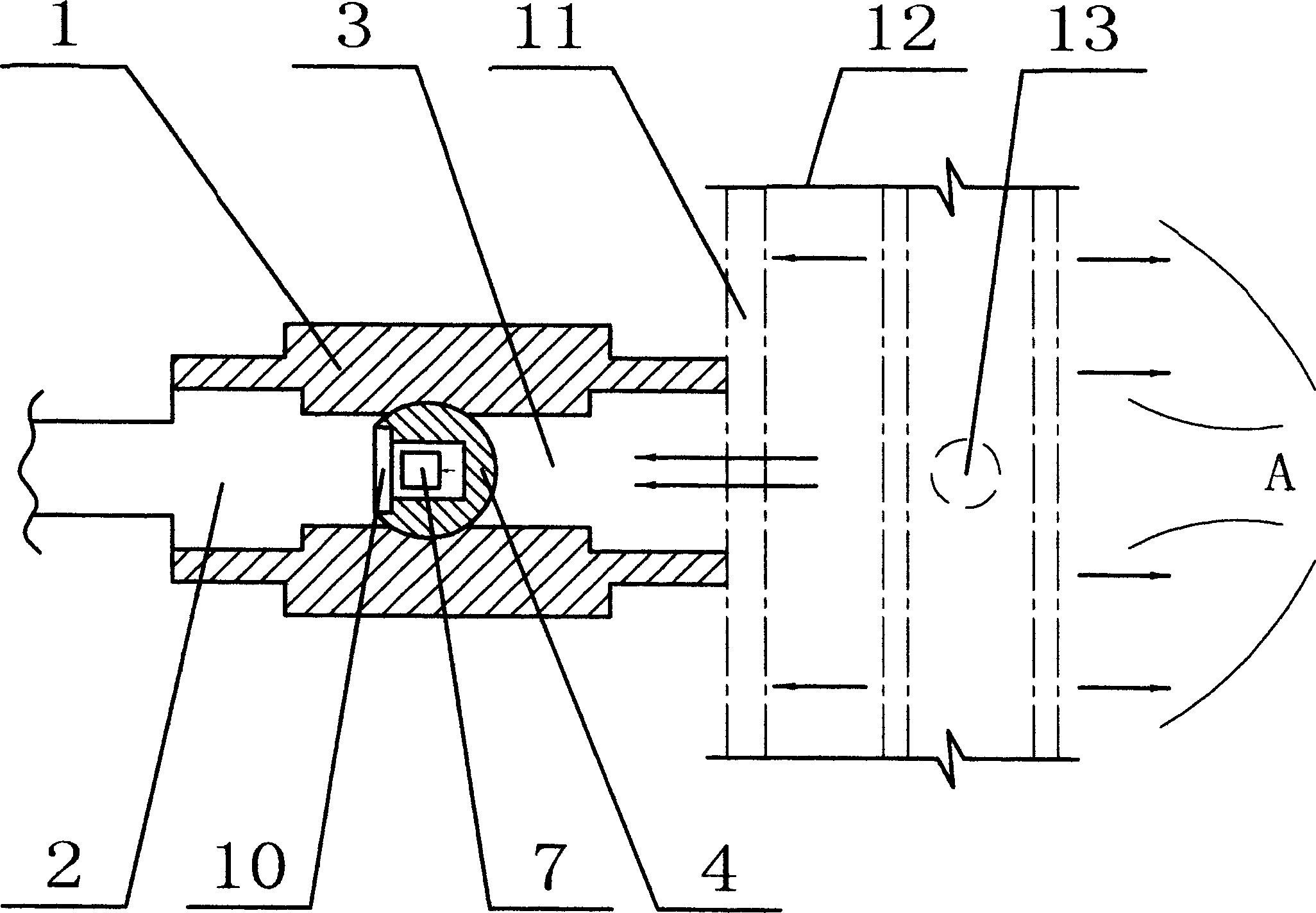

[0035] Figure 1~4 A first embodiment of an ultraviolet radiation sensing system is described. figure 1 and figure 2 illustrates the first embodiment of the sensing system in the first or detection position, while image 3 and Figure 4 The first embodiment of the sensing system in the second or cleaning position is illustrated.

[0036] Such as Figure 1~4 As shown, the ultraviolet radiation sensing system mainly includes a casing (1), and a first cavity (2) and a second cavity (3) are arranged in the casing (1), and the first cavity (2) and the second cavity A sensing device casing (4) is inserted between the two cavities (3). The sensing device housing (4) is connected to the motor (6) through a shaft (5).

[0037] A sensing photosensitive diode (7) is arranged in the sensing device casing (4), and the sensing photosensitive diode (7) is connected on the cable (8). The sensing photodiode can detect and respond to ultraviolet radiation with a wavelength in the range ...

Embodiment 2

[0045] Figure 5-8 A second embodiment of an ultraviolet radiation sensing system is illustrated, Figure 5 and Figure 6 illustrates the second embodiment of the sensing system in the first or detection position, while Figure 7 and Figure 8 A second embodiment of the sensing system in the second or cleaning position is illustrated.

[0046] Such as Figure 5-8 As shown, the ultraviolet radiation sensing system mainly includes a casing (14), and a first cavity (15) and a second cavity (16) are arranged in the casing (14), and the first cavity (15) and the second cavity A spherical casing (17) is inserted between the two chambers (16), and the spherical casing (17) is connected on the motor (19) by a shaft (18).

[0047] A sensing photodiode (20) is arranged in the spherical casing (17), and the sensing photodiode (20) is connected on the cable (21). The cable (21) is drawn out from the conduit (22) connected on the casing (14). The spherical casing (17) is also provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com