Acrylic resin, resin boards, transparent electrode boards for touch panels, touch panels, and processes for production of them

A manufacturing method and transparent electrode technology, applied in acrylic resin, resin plate, transparent electrode plate for touch panel, touch panel and their manufacturing fields, can solve problems such as plate cracking and plate cracking, prevent damage, improve durability Thermal performance, achieve lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

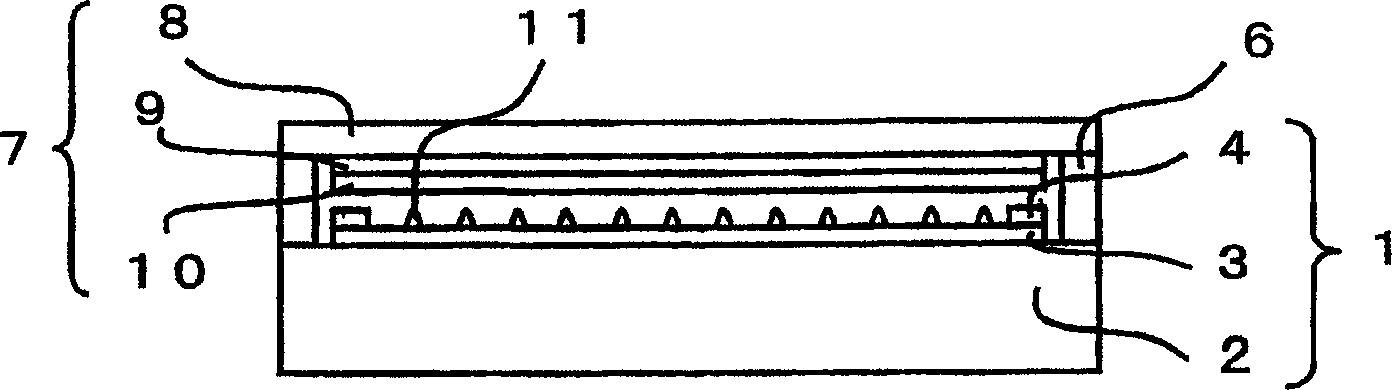

Image

Examples

Embodiment 1

[0140] In 10 parts of isostearyl methacrylate ("NK ester S-1800M" manufactured by Shin Nakamura Chemical Industry Co., Ltd.), 10 parts of methyl methacrylate and bis (oxymethyl) tricyclo [5, 2, 1 ,0 2,6 ] In 100 parts of a mixture of 80 parts of decane dimethacrylate, 0.05 parts of 2,2'-azobis(2,4-dimethyl-4-methoxyvaleronitrile) as a polymerization initiator were mixed, 0.05 part of tert-butyl peroxy pivalate, 0.05 part of tert-hexyl peroxy isopropyl carbonate and 0.03 part of terpinolene as a polymerization regulator, and the resulting mixture is put into a suction filter bottle, stirred, and vacuum removed gas to obtain a polymerization mixture.

[0141] The polymerization mixture was poured into a mold formed by inserting a gasket between a pair of tempered glass sheets at a distance of 1.7mm, and air bubbles were removed, and then placed in a heating furnace, and polymerized at 55°C for 1 hour, then at 50°C for 1 hour, and then heated at 135°C Polymerized for 3 hours. ...

Embodiment 2~24

[0143] [Examples 2-24, Comparative Examples 1-9]

[0144] Except having used the raw material composition shown in Tables 1-6, it carried out similarly to Example 1, and produced the acrylic resin board. The evaluation results are shown in Tables 1-6.

Embodiment 25

[0146] In Example 1, 0.05 part of n-dodecyl mercaptan was further added as a chain transfer agent to the polymerization mixture, and the rest was carried out in the same manner as in Example 1 to produce an acrylic resin plate. The evaluation results are shown in Table 7. Moreover, bis(oxymethyl)tricyclo[5,2,1,0 2,6 ] The residual monomer amount of decane dimethacrylate was 2.09%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com