Tubular supporting carbon molecular sieve membrance and its preparing method

A technology of carbon molecular sieve and tubular support, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

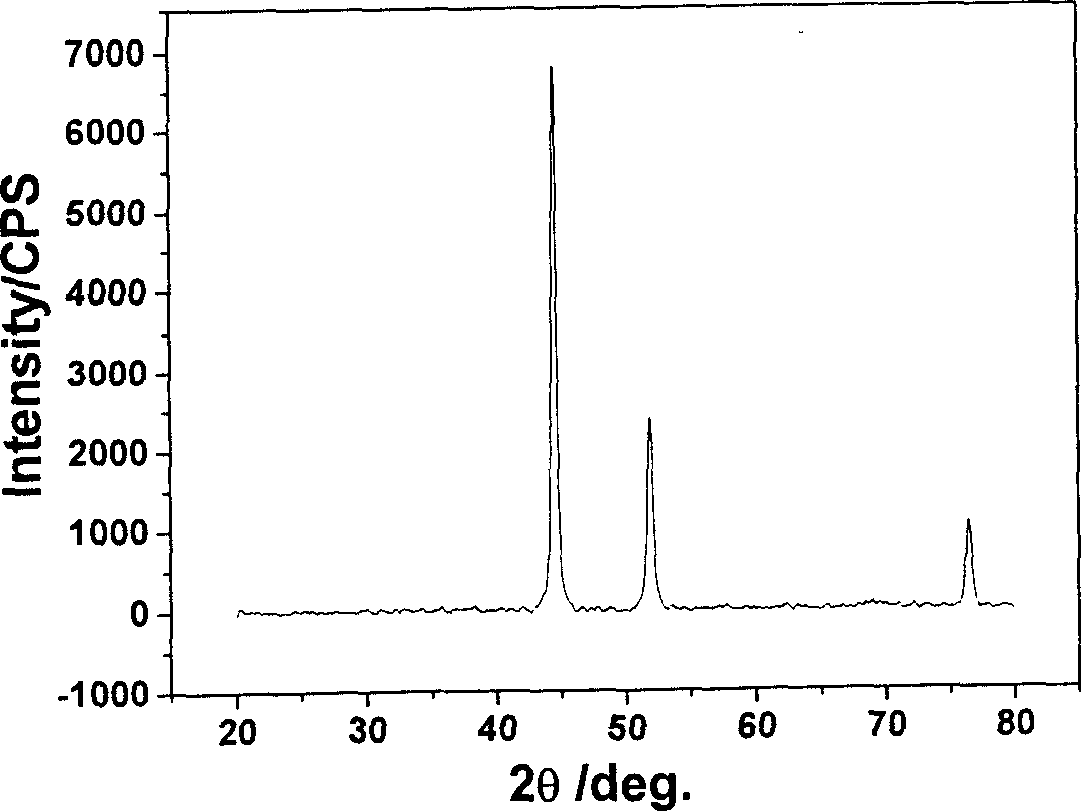

Image

Examples

Embodiment 1

[0035] After washing / drying the alumina ceramic tube with a pore size of 0.2 μm, the prepared stable aluminum sol film was coated by dipping method for 4 seconds, dried at room temperature for 24 hours, and dried in vacuum for 6 hours. Raise the temperature to 600°C at a rate of 1°C / min, keep it warm for 3 hours, and lower the room temperature naturally. The above steps are repeated 2 to 3 times to obtain a tubular support body with a nanopore diameter.

Embodiment 2

[0037] Wrap the outer surface of the aluminum sol-modified tubular support with nanopores with polytetrafluoroethylene, slowly dip it in 40% phenolic resin in anhydrous ethanol solution for 2 minutes, take it out slowly and at a uniform speed, turn it over and place it vertically, Dry at room temperature for 24 h, vacuum dry for 6 h, and then 2 Programmed temperature rise carbonization under protection. Raise the temperature to 600°C at a rate of 1°C / min, keep it warm for 3 hours, and then cool down to room temperature naturally. Repeat the above steps 3 times to obtain a qualified carbon membrane, and the membrane tube number is M1-3.

[0038] H measured at 30°C 2 , CO 2 , O 2 and N 2 The permeation fluxes were 2.0×10 -9 , 3.8×10 -9 , 1.0×10 -10 and 6.0×10 -11 mol·s -1 m -2 ·Pa -1 , gas selectivity H 2 / N 2 , CO 2 / N 2 , O 2 / N 2 and CO 2 / H 2 33, 63, 1.7 and 1.9 respectively.

Embodiment 3~7

[0040] Add self-made nano-nickel with a particle size of 57nm to 40% phenolic resin in anhydrous ethanol solution, the content of nano-nickel is 1%, 3%, 5%, 7.5% and 10%, and the film is repeatedly coated for 2-3 times. The carbon membranes prepared for the second time, the labels of the membrane tubes are M2-3, M3-3, M4-2, M5-2 and M6-2 respectively. When the nickel content in the carbon film is between 1% and 5%, as the nickel content increases, the H 2 The permeation flux decreases gradually. When the nickel content in the carbon membrane is 5%, the H 2 The permeation flux reaches a minimum, measured at 30 °C for H 2 The permeate flux is 8.0×10 -11 mol·s -1 m -2 ·Pa -1 ; while CO 2 The permeation flux increases gradually. When the nickel content in the carbon membrane is 5%, the CO 2 The permeation flux reaches 3.0×10 -9 mol·s -1 m -2 ·Pa -1 , CO 2 / H 2 The gas selectivity reaches a maximum of 38. When the nickel content is between 5% and 10%, with the gradual...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com